Maintaining and repairing your equipment requires a clear understanding of its inner workings. Knowing how each component fits together and functions is crucial for troubleshooting and ensuring optimal performance. This guide will walk you through the essential elements of the machine, helping you identify and manage potential issues.

Whether you’re replacing worn-out components or simply performing routine maintenance, having a visual representation can significantly ease the process. A well-organized map of the tool’s structure not only saves time but also enhances safety during handling. By understanding the function of each part, you can keep your equipment running smoothly for years to come.

Effective maintenance depends on your ability to spot any worn or damaged sections quickly. With the right knowledge, you’ll be able to prevent costly repairs and extend the lifespan of your equipment.

Understanding Key Components of Your Tool

Every tool is made up of various essential elements that work together to deliver precise and efficient performance. Understanding these components and their functions allows you to make informed decisions during maintenance, ensuring that each part is functioning properly. From the drive mechanism to the cutting section, each part plays a crucial role in the overall operation.

Among the most important elements are the motor, which powers the machine, and the tension system, which ensures the proper alignment and stability of the cutting mechanism. Knowing how to recognize wear or damage in these parts can help you maintain consistent cutting precision and prevent unnecessary breakdowns.

Regular inspection of each part allows you to address minor issues before they evolve into more significant problems. The better your understanding of the tool’s components, the easier it becomes to identify the source of any malfunction and take quick action.

Additionally, keeping track of each element’s lifespan can help in planning proactive replacements, reducing downtime. Proper knowledge of the entire system will ultimately lead to improved performance and extended tool life.

How to Read a Tool Component Layout

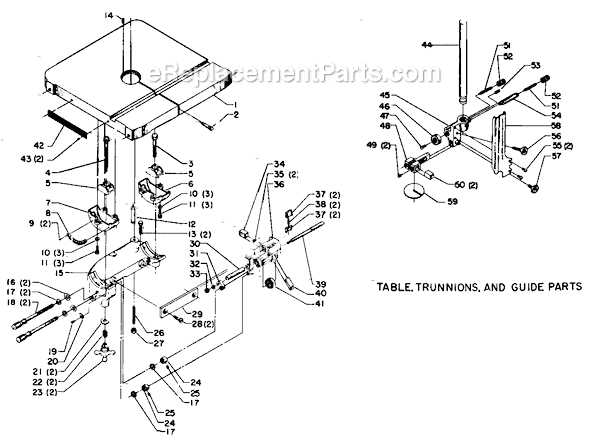

Interpreting a component layout for your equipment is essential for understanding how all elements interact. These layouts provide a detailed representation of the internal structure, highlighting key sections and their specific functions. Knowing how to read such diagrams allows for efficient troubleshooting and replacement of damaged components.

The layout typically includes labeled parts that correspond to the actual sections of the tool. Each component is marked with a reference number, which can be cross-referenced with the tool’s manual for additional details. By following these numbers, you can pinpoint the location of each part and understand its role in the operation.

Focus on the key areas such as the motor, tension system, and cutting mechanisms. Understanding these areas will help you quickly identify potential issues when inspecting the tool. A well-structured layout offers clarity, enabling you to perform repairs and adjustments more effectively.

By becoming familiar with the layout, you’ll not only improve your maintenance routine but also ensure that your equipment runs smoothly. Efficient reading of component layouts can significantly reduce repair time and enhance overall performance.

Replacing Components on Your Tool

Replacing worn or damaged components is a crucial aspect of maintaining your equipment’s functionality. Over time, some elements may deteriorate due to regular use, and addressing these issues promptly can prevent further damage and improve performance. Knowing when and how to replace specific sections is key to ensuring smooth operation.

Start by identifying the affected components. Refer to the tool’s layout or user manual to locate each element that needs replacement. Once identified, carefully remove the faulty part and replace it with a new, compatible component. It is essential to choose the right replacement to match the specifications of the tool.

Make sure to follow the manufacturer’s guidelines during the replacement process to avoid improper installation. Proper alignment and tensioning are critical for ensuring the new component works seamlessly with the rest of the tool. Regular replacement of key elements will enhance efficiency and extend the tool’s lifespan.