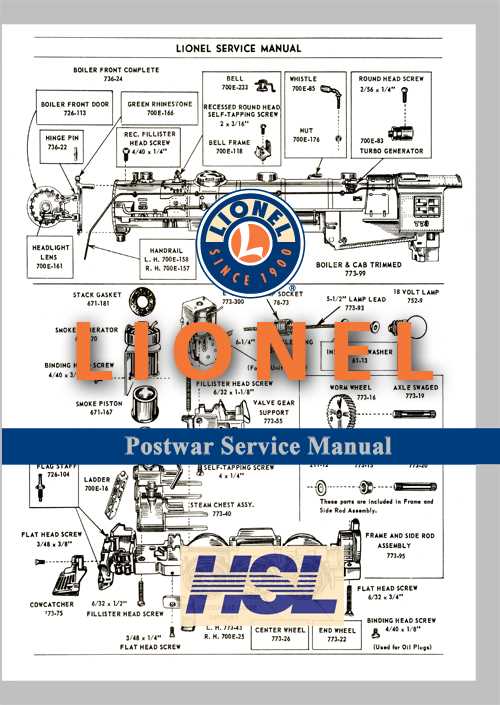

When working with model train systems, having a clear visual guide for assembly, maintenance, and repairs can make all the difference. Whether you’re troubleshooting a malfunction or upgrading a component, these visual resources help you identify the right pieces and understand how they fit together.

These guides offer a detailed look at each individual component, often showing how parts interact and providing insights on where issues might arise. By referring to these illustrations, you can efficiently navigate through complex setups and ensure all pieces are correctly aligned and functioning.

Mastering these resources allows hobbyists and professionals alike to streamline their work process and tackle repairs with confidence. Clear, easy-to-understand visuals reduce the guesswork involved, ensuring smoother operations and a more enjoyable experience.

Understanding Model Train Component Guides for Beginners

For those new to the world of model railroading, understanding how to read and interpret visual guides for train assembly and repair is essential. These resources provide a detailed look at every element of the system, offering clarity on the placement and function of each part. Whether you are setting up a new system or troubleshooting an existing one, these visuals help make sense of complex layouts and mechanisms.

Basic Structure of the Visual Guides

These guides typically feature clear images or drawings that label each individual component, showing how everything fits together. Beginners can learn how to match the right parts and understand their roles within the system. Over time, you’ll become more familiar with how to navigate these images, making it easier to locate specific components when needed.

Why Understanding These Guides is Crucial

Having a strong grasp of these visual aids ensures that you can quickly identify and fix problems in your model train setup. By following the illustrated steps, even complex repair processes become more approachable. This knowledge not only helps in repairs but also enhances your ability to expand or customize your system efficiently.

How to Use Visual Guides for Train Repairs

When it comes to repairing your model train system, visual guides can be incredibly useful in pinpointing issues and ensuring you address them correctly. These resources provide clear illustrations of the various components, making it easier to see how everything is supposed to fit together and where problems might arise. Knowing how to use these guides effectively can significantly speed up the repair process.

Steps for Effective Repair Using Guides

Follow these steps to make the most of your repair visuals:

- Identify the Issue – Before consulting any guide, make sure you know what isn’t working properly. Is it a malfunction in the engine, track, or accessories?

- Locate the Relevant Guide – Find the correct visual that matches the specific area you’re working on. These guides often have sections dedicated to different train types or functions.

- Examine the Diagram Carefully – Look for labels that indicate the placement of each component. Pay attention to the connections and how pieces should align.

- Remove and Inspect Parts – After identifying the parts in the guide, gently remove the faulty component and check it for damage or wear.

- Compare with Visuals – Once the part is out, compare it with the guide to ensure it’s properly placed or intact. If you need to replace it, find the correct replacement based on the visual references.

Tips for Smooth Repairs

- Work Slowly – Avoid rushing through the steps. Thoroughly check the visual guide to avoid missing any important details.

- Keep Tools Organized – A clean and organized workspace ensures you don’t lose any small components during the repair.

- Consult Multiple Resources – If one visual guide doesn’t provide enough detail, try another source to cross-check and clarify your steps.

Common Issues Identified with Component Guides

When working with visual guides for your model train system, it’s important to be aware of the common issues that can arise during repairs. These illustrations are designed to simplify troubleshooting, but sometimes, discrepancies or misunderstandings can make the repair process more challenging. By recognizing these issues early, you can avoid unnecessary mistakes and streamline the maintenance process.

One of the most frequent problems is difficulty in accurately identifying components, especially when the visuals lack sufficient detail or clarity. In some cases, small parts may be overlooked, leading to incomplete repairs. Another common issue is interpreting how components fit together, which can be confusing if the diagram doesn’t clearly indicate the proper alignment or sequence of assembly.

Additionally, outdated or incorrect guides may not reflect the latest model updates, causing confusion when you try to match parts. It’s also possible to encounter inconsistencies between different sources, which can make it hard to know which version of the guide is the most accurate. Understanding these common challenges will help you approach repairs with greater awareness and confidence.