For anyone who relies on power equipment, understanding the internal workings and how to maintain it is essential for long-lasting performance. Troubleshooting, repairing, and keeping track of various components can often be challenging, but having the right reference materials makes all the difference.

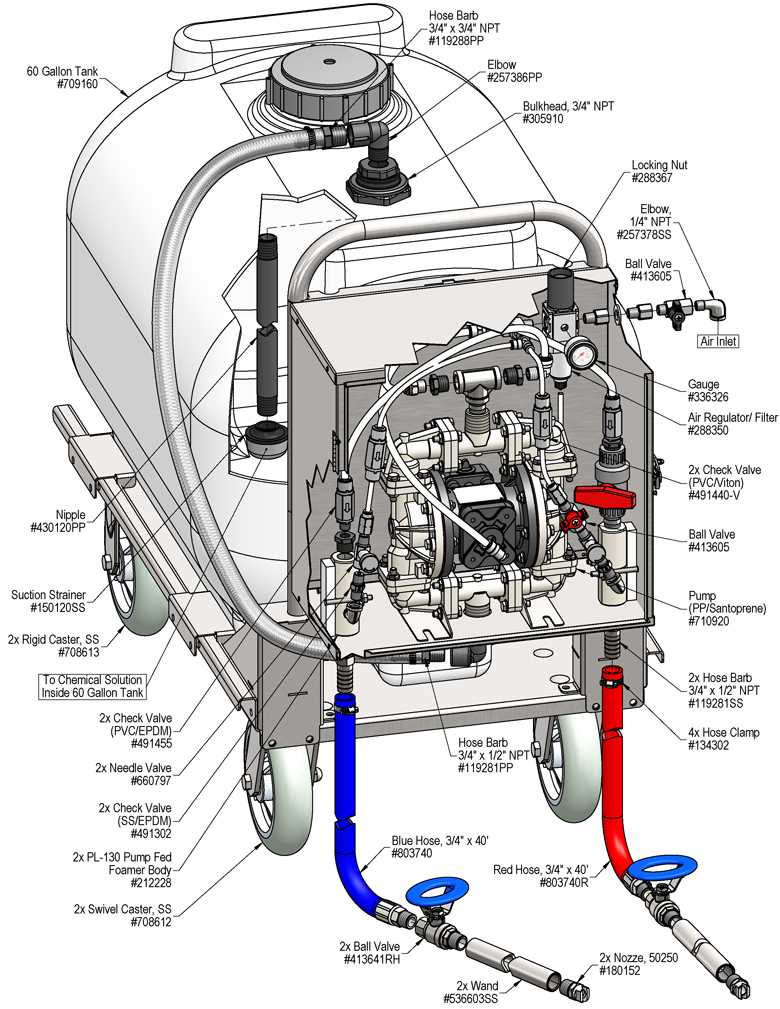

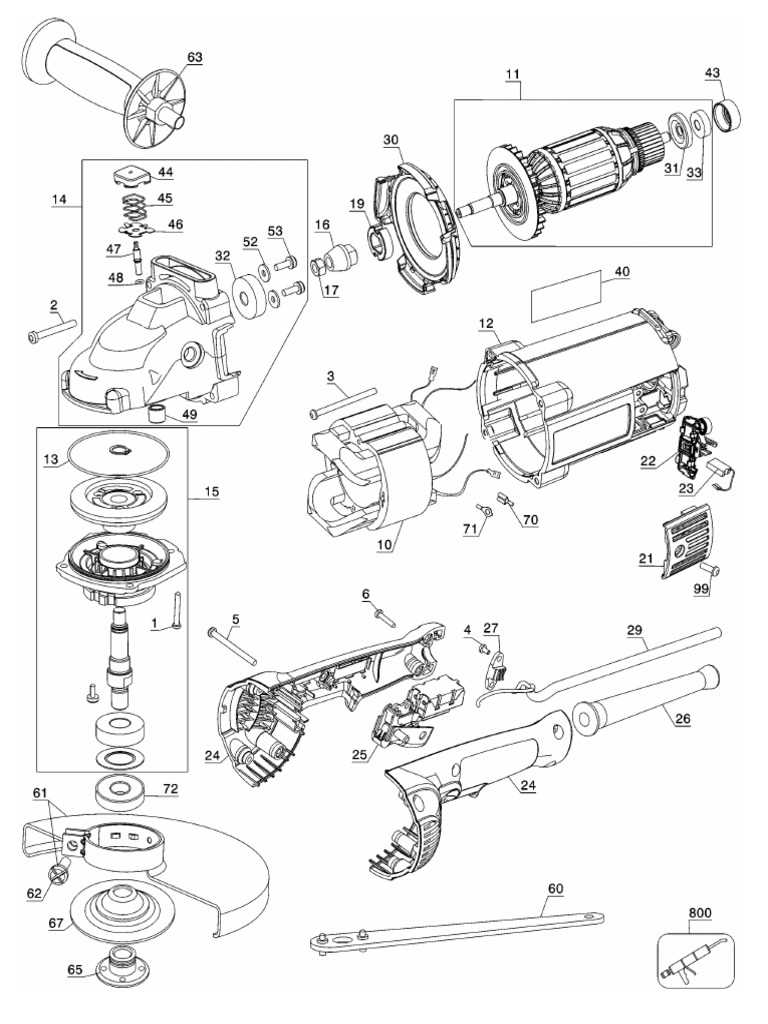

By examining detailed illustrations and schematics of the equipment, you can gain a clear understanding of how each part functions within the larger system. This guide will walk you through key features, highlight common issues, and offer practical solutions to keep your machine running smoothly for years to come.

Knowing the right parts and how to service them will ensure that you can confidently tackle any maintenance tasks or repairs. Whether you’re a professional or a hobbyist, these resources are invaluable for a successful upkeep strategy.

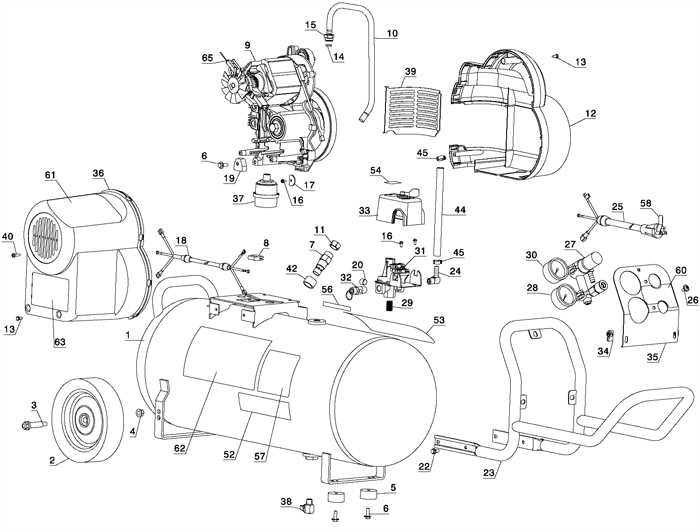

Understanding Key Components of Your Air Compressor

When working with any mechanical device, a clear understanding of its individual elements and their functions is essential. Each component plays a specific role in the overall performance and efficiency of the machine. By knowing how these parts interact, you can better maintain and troubleshoot your equipment.

Essential Elements for Smooth Operation

The heart of any air compressor lies in its motor and pump assembly. These two key elements work together to compress air and store it for use. Other critical parts include valves, pressure switches, and tanks, each contributing to the overall functionality and safety of the device.

Identifying Common Components and Their Roles

Understanding each part’s role helps you recognize potential issues before they escalate. For example, the air intake valve regulates airflow, while the pressure switch ensures the system maintains the correct pressure level. Regular inspection and familiarity with these components enable you to perform effective maintenance and repairs.

How to Use the Schematic Effectively

Having a visual reference for your equipment’s internal layout is crucial for accurate repairs and maintenance. By using a well-structured illustration, you can easily identify each component and understand how they fit together within the system. This guide will help you leverage such references to ensure efficiency during repairs.

Step-by-Step Approach to Reading the Schematic

Start by locating the main sections of the image, which are typically divided by function. Each section corresponds to a different part of the machine, such as the motor or pressure system. Understanding the layout allows you to quickly pinpoint the area in need of attention and avoid unnecessary disassembly.

Tips for Troubleshooting with Visual Aids

To diagnose issues effectively, match the problem you’re experiencing with the corresponding component in the schematic. For example, if the compressor is not building pressure, look closely at the pressure relief valve and the regulator section for potential blockages or malfunctions. A clear understanding of the image can lead to faster and more accurate repairs.

Common Issues and Fixes for Air Compressors

Despite their reliability, air compressors can experience various issues over time. Understanding common problems and knowing how to address them can save you time and money on repairs. Here are some of the most frequent challenges and their solutions.

Air Compressor Not Starting

If your compressor is failing to start, the issue could lie with the motor, electrical connections, or the pressure switch. To troubleshoot this problem:

- Check the power source and ensure that the unit is plugged in properly.

- Inspect the pressure switch for any visible signs of damage or malfunction.

- Test the motor and check for any electrical faults or blown fuses.

Loss of Pressure

When your compressor struggles to maintain pressure, several components could be to blame. Common causes include:

- Leakage in the hose or fittings: Check for cracks or holes in the air hose and replace any damaged sections.

- Faulty intake valve: Ensure the intake valve is working correctly and free from debris.

- Issues with the regulator: Inspect the regulator and adjust it as necessary to maintain proper pressure levels.