For anyone operating a heavy-duty vehicle, understanding the components and mechanisms that keep it running smoothly is crucial. Proper maintenance ensures longevity and optimal performance, especially when tackling challenging tasks in the field. Whether you are an experienced operator or a first-time user, having clear and accurate references to your machine’s structure can make a significant difference in repair and upkeep efficiency.

Efficient repair starts with knowing exactly which parts need attention and how they interact with each other. Using a detailed visual guide for a machine’s assembly helps to quickly locate the issue and prevent unnecessary disassembly. Identifying worn-out or damaged parts accurately can save time and reduce repair costs, enabling the owner to focus on what matters most–getting the job done.

Having a comprehensive reference of all components also allows for easy identification when ordering replacements. With the right information at hand, you can be confident in finding the best solutions and ensuring that your equipment stays in top condition, minimizing downtime and maximizing productivity.

Understanding Tractor Components

Having a clear understanding of a vehicle’s internal elements is essential for any operator. When it comes to large machinery, each component plays a specific role in ensuring smooth performance and reliability. By familiarizing yourself with these critical sections, you can more effectively diagnose issues, perform necessary repairs, and maintain the equipment over time.

For instance, recognizing the core sections such as the engine, transmission, and hydraulics allows for quicker troubleshooting and targeted interventions. Each system interacts with others, meaning that one malfunctioning element can impact multiple areas. Knowing how each piece contributes to the overall operation enables the user to approach maintenance with confidence and precision.

By studying these assemblies in detail, it becomes easier to identify when a specific element needs attention. Whether dealing with wear, damage, or simply routine upkeep, the ability to pinpoint problem areas quickly will save both time and resources. The key to efficient operation lies in understanding the functionality and structure of the machine’s most crucial components.

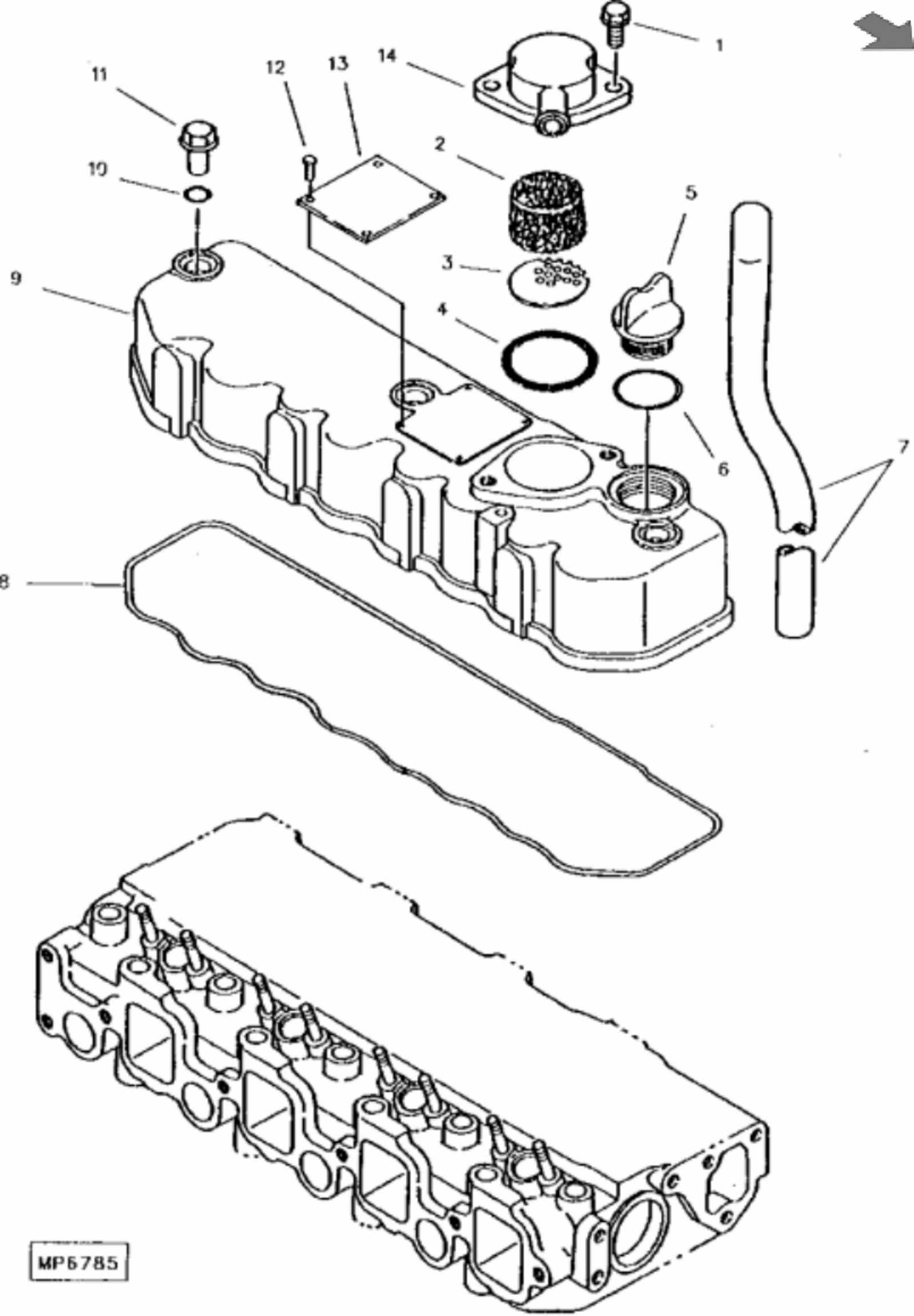

How to Use the Parts Diagram

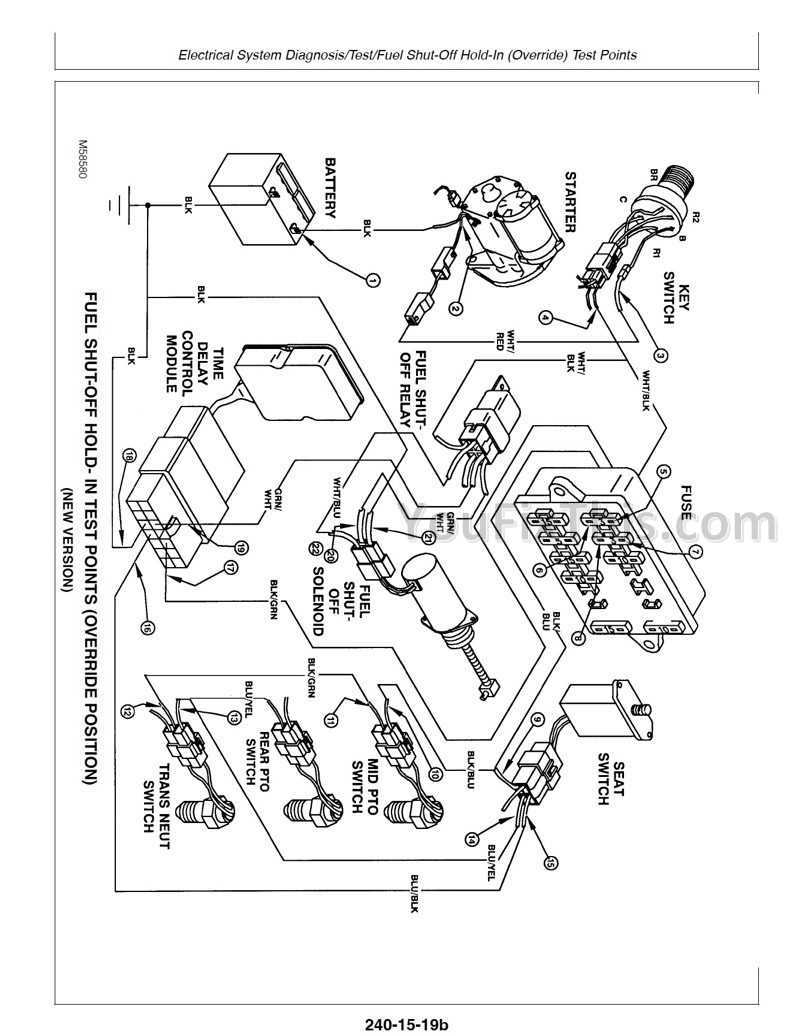

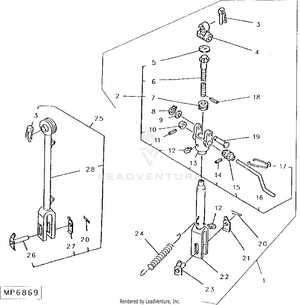

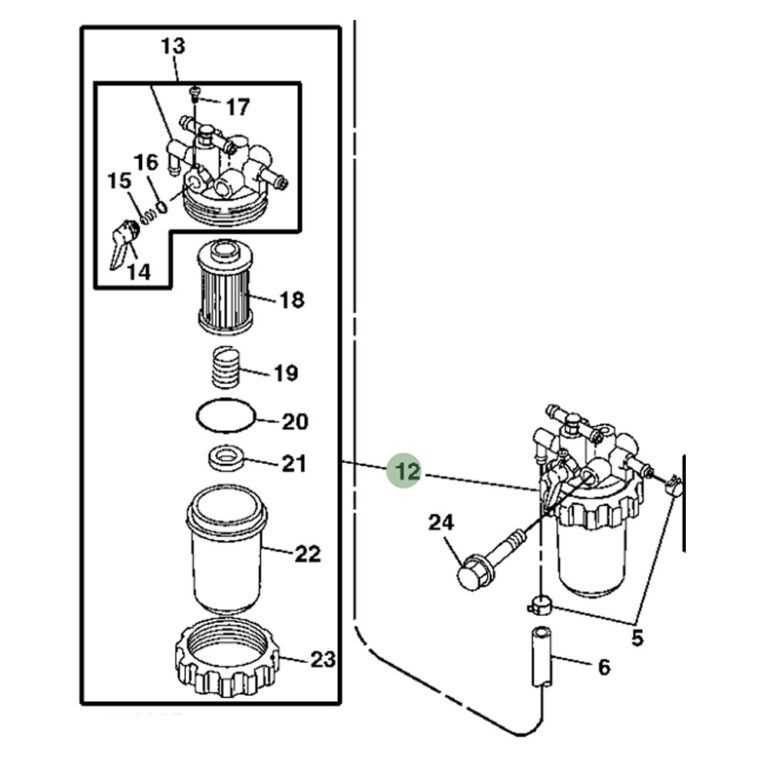

To efficiently maintain and repair a machine, it’s essential to know how to interpret visual guides that map out its internal structure. These guides provide a detailed look at all critical components, helping you to identify the exact location and function of each part. Understanding how to use these references can drastically improve the accuracy and speed of any repair process.

When consulting the visual map, start by locating the section that corresponds to the area in need of attention. These guides often divide the machine into various categories, such as the engine, transmission, or hydraulic systems. Once you’ve pinpointed the relevant section, you can identify specific components, which can then be cross-referenced with the manufacturer’s part numbers or descriptions to ensure proper replacements.

Additionally, visual references can be especially helpful for identifying parts that are prone to wear or need regular servicing. By regularly consulting these resources, you can stay ahead of potential issues, making repairs or replacements as needed before they affect the machine’s performance.

Common Repairs for Heavy-Duty Machinery

Maintenance and repair are an inevitable part of operating heavy machinery. Over time, certain components may show signs of wear or failure, requiring attention to keep the equipment running efficiently. Recognizing common issues early on can help prevent more significant breakdowns, ensuring minimal downtime and optimal performance.

Engine and Transmission Troubles

One of the most frequent repairs involves the engine and transmission system. These areas can experience wear due to consistent use, often leading to overheating, leaks, or poor performance. Regular inspection of belts, hoses, and fluid levels is crucial for identifying potential problems before they escalate. If an issue is detected, replacing faulty components promptly can extend the life of the entire system.

Hydraulic System Maintenance

The hydraulic system is another key area that often requires repair. Leaks, pump failure, or issues with the cylinders can disrupt the overall functionality of the machine. Inspecting hoses and seals regularly helps identify small problems that could lead to more serious damage. Early replacement of worn-out parts can prevent costly repairs down the line and ensure the machine’s hydraulic systems operate smoothly.