When dealing with heavy lifting equipment, it’s crucial to have a clear understanding of the key elements that make up the system. These components work together to ensure smooth operation and safety, whether it’s moving large loads or facilitating precise control. The success of any lifting operation heavily depends on the functionality and reliability of these parts.

Each part has a unique role that contributes to the overall performance. From the motor that powers the system to the cables that guide the load, every element must be carefully designed and maintained. Knowing how each part interacts with the others is essential for operators and maintenance teams to ensure optimal efficiency and safety.

By exploring the different sections of these systems, one can better appreciate their importance in daily industrial operations. Proper knowledge helps avoid costly repairs and downtime, improving the longevity of equipment and ensuring that it meets safety standards. In the following sections, we’ll delve into the core components of such systems and their functions in detail.

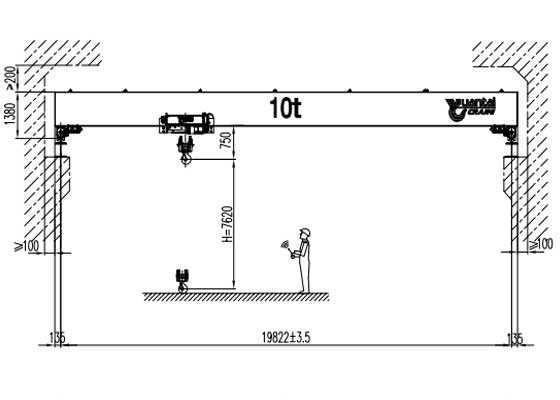

Key Elements of Lifting Systems

To ensure the efficiency and safety of lifting operations, it’s essential to understand the main components that make up the machinery. These crucial elements work in unison to move heavy loads with precision, providing both power and control in a variety of industrial settings. Each element is designed to serve a specific purpose, ensuring that the entire system operates smoothly.

Important Components

- Drive Motor – Powers the system and controls the movement of the lifting mechanism, offering both speed and torque.

- Load-bearing Mechanism – Includes pulleys, cables, and drums that support and transport the load efficiently.

- Control System – Allows the operator to manipulate the machine, adjusting speed, direction, and load capacity.

- Structural Frame – Provides the necessary support to hold all the components in place while withstanding heavy loads and stress.

Functionality and Interaction

Each element works in harmony with others to create a balanced and effective system. The motor drives the load-bearing components, while the control system allows for precise adjustments in speed and load handling. Without a sturdy frame, however, the system wouldn’t have the necessary support to function properly. Proper interaction among these elements guarantees safe and reliable lifting operations in any setting.

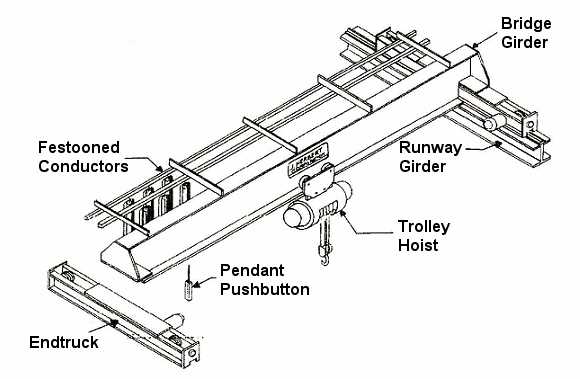

How to Identify Lifting System Components

Recognizing the key elements of lifting machinery is essential for effective operation and maintenance. By understanding the distinct characteristics and functions of each component, operators can quickly identify any issues that may arise. Proper identification ensures that necessary repairs or replacements are made on time, avoiding costly downtime and enhancing safety during lifting tasks.

Common Features of Key Components

- Motor Unit – Typically located near the drive system, it’s often marked with technical specifications and power ratings.

- Load Support Mechanism – These parts, such as ropes or pulleys, are designed for heavy lifting and often show signs of wear over time, which helps in identifying them.

- Control Panel – Usually located near the operator’s position, this component allows the user to manipulate the system’s movement and often includes labeled buttons or switches.

- Structural Frame – This is the sturdy base of the system, often made of metal, and it is typically the most visible part, providing support for all internal components.

Visual and Functional Indicators

Each component of the system can often be identified by its specific function and physical characteristics. The motor, for example, will have electrical connections and power ratings displayed on its body. Similarly, the load-supporting components, such as pulleys and cables, will be visibly worn after heavy use. Understanding these signs and knowing where to look for specific labels or markings makes identification easier and more efficient.

Understanding the Function of Each Part

Each component of a lifting system plays a critical role in ensuring the machinery operates smoothly and efficiently. Understanding the specific function of every element allows operators and maintenance teams to optimize performance and troubleshoot issues effectively. By comprehending how each part interacts with the others, it becomes easier to maintain system reliability and extend its lifespan.

The drive motor, for example, is responsible for powering the entire system, controlling both speed and direction. Without it, the entire operation would grind to a halt. Similarly, the load-supporting mechanisms, including cables and pulleys, allow the system to bear heavy weights and control their movement. These components are crucial for both the safety and efficiency of the operation, as they directly affect how well the load is handled.

Equally important is the control system, which enables the operator to adjust the operation, ensuring precision and accuracy in every move. The structural frame, while not often noticed, serves as the foundation that holds all these components in place. It must be durable and resistant to stress to ensure the system’s stability, especially during heavy-duty tasks.

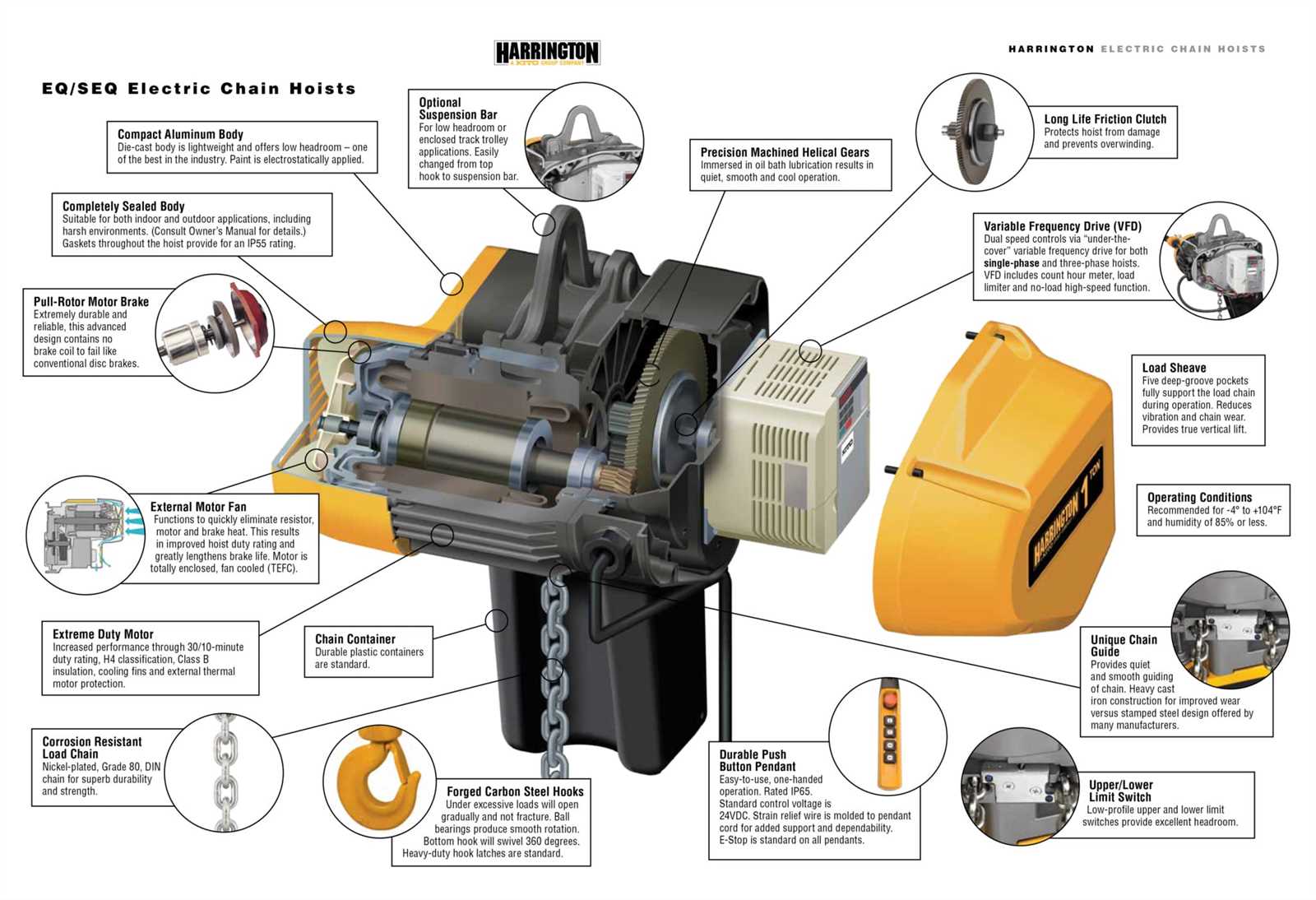

Detailed Breakdown of Crane Hoist Parts

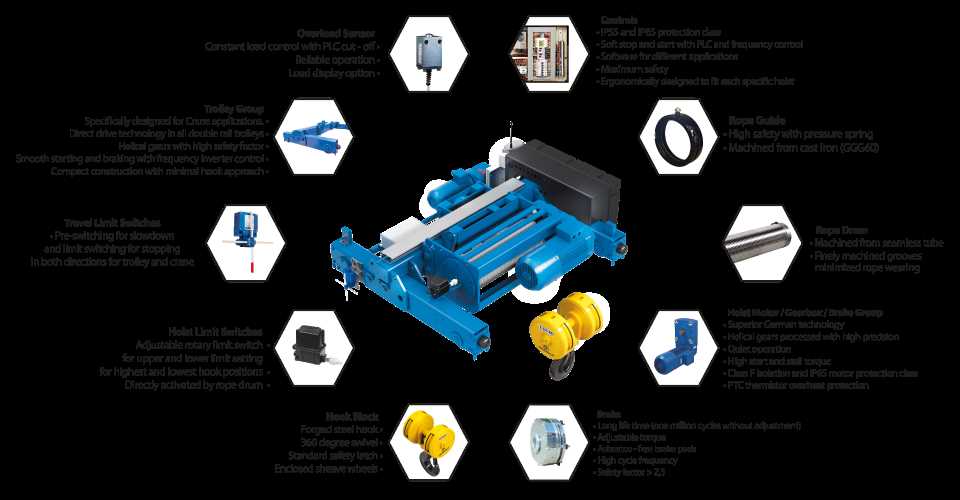

Understanding the components of a lifting mechanism is essential for ensuring its effective operation and safety. In this section, we will explore the individual elements that make up the system, focusing on their function, importance, and interaction with each other.

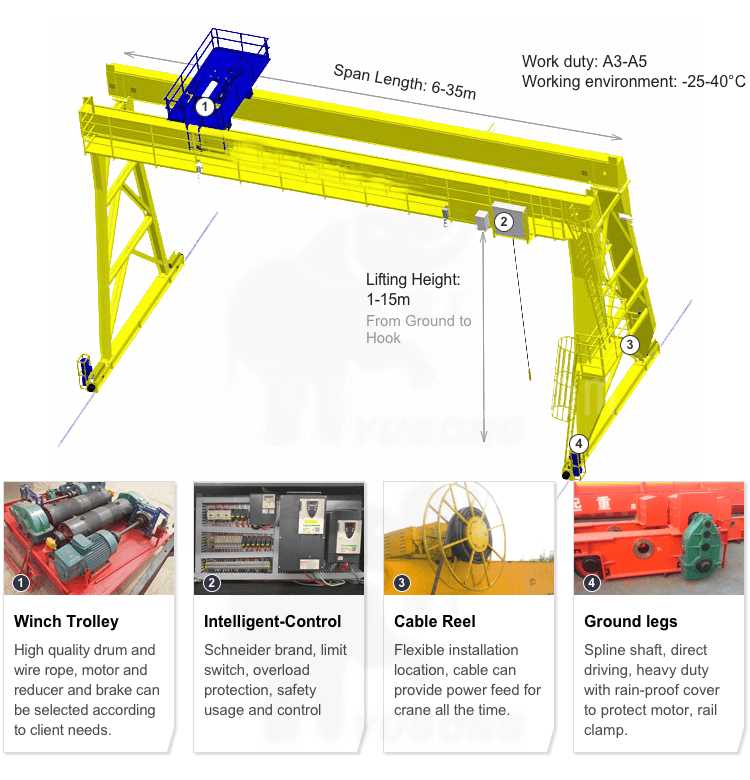

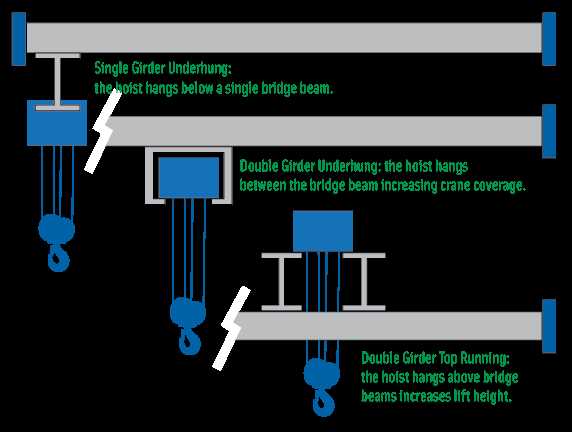

Core Elements of the Lifting Mechanism

The heart of any lifting equipment lies in its primary components, which work together to achieve the desired load handling. Each element, from the drive motor to the load-bearing components, plays a crucial role in ensuring smooth and safe operations. For instance, the motor powers the system, while the load-bearing structures support the weight and ensure stability throughout the process.

Supporting Structures and Mechanisms

Alongside the primary elements, there are several support systems designed to enhance the overall efficiency and durability. These include the cables and pulleys that help transfer force and the brake mechanisms that prevent unwanted movement. The collaboration of these parts contributes to the reliability of the entire system, reducing the risk of malfunction or failure.

Common Issues and Maintenance Tips

Regular usage of lifting equipment can lead to wear and tear over time, resulting in various operational challenges. Identifying these issues early and performing the necessary upkeep can prevent costly repairs and ensure safe and efficient functionality.

Frequent Problems and Solutions

One common issue is the malfunctioning of the drive system, which may cause the entire mechanism to operate erratically. Regular inspection of the motor and electrical components is crucial. Another issue is the wear on load-bearing elements, which can lead to instability. It’s essential to check for any signs of damage or strain on these elements and replace them when needed.

Maintenance Practices for Longevity

To maintain optimal performance, ensure regular lubrication of moving components to reduce friction and prevent overheating. Cleaning all elements to avoid debris buildup is also important for preventing damage. In addition, performing periodic checks on the brake and safety systems will help to identify any potential malfunctions before they lead to accidents.