When maintaining and repairing heavy machinery, a clear understanding of the equipment’s structure is essential. A visual representation of the key elements can make it easier to identify each component and its role in the system. Such guides allow users to navigate complex assemblies with ease, ensuring efficient troubleshooting and repairs.

Accurate reference tools are invaluable for anyone working with large machines. They provide insights into how parts fit together, where potential issues may arise, and how to replace or repair individual components. For both beginners and professionals, these resources offer a roadmap for managing equipment in the most effective way.

Having access to a comprehensive reference that highlights all crucial components helps save time and reduce errors. This knowledge is especially important when handling machinery that requires precise adjustments to maintain performance. Whether you’re dealing with routine maintenance or more serious repairs, such guides simplify the process and enhance understanding.

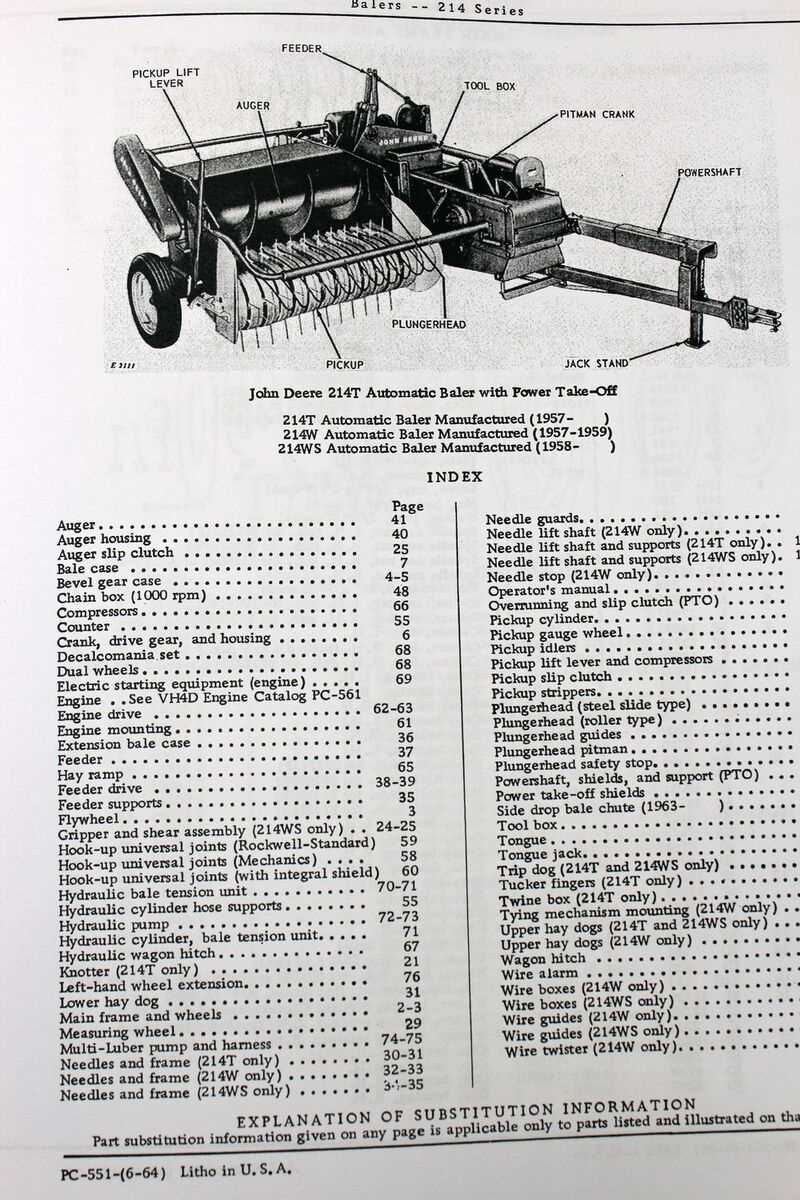

Understanding the John Deere 214 Parts

To effectively maintain and repair complex machinery, it is essential to have a clear understanding of its individual components. Each element plays a specific role in ensuring the proper functioning of the entire system. Familiarity with how parts interact with each other and contribute to overall performance can significantly enhance troubleshooting and repair processes.

When working with large equipment, having detailed knowledge of its structure helps identify wear or damage in critical areas. Understanding the design of each piece, from the smallest bolt to larger mechanisms, provides valuable insight into their function and replacement procedures. Recognizing the importance of each part allows for more efficient maintenance and longer equipment lifespan.

Additionally, recognizing common wear points and identifying possible failures in the machinery’s structure can prevent more costly repairs down the line. Familiarity with the essential components ensures that maintenance tasks are carried out with precision and confidence, reducing downtime and enhancing operational efficiency.

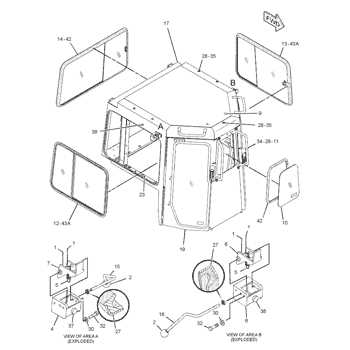

How to Read the John Deere 214 Diagram

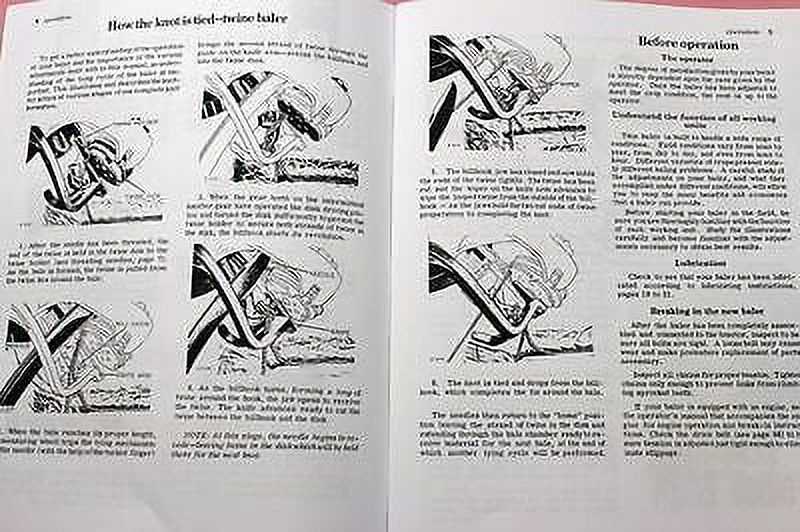

Understanding a visual representation of machinery components is crucial for efficient repairs and maintenance. These guides are designed to show the relationships between various elements and help identify each one’s function. Learning how to interpret such layouts simplifies troubleshooting and speeds up the repair process.

First, focus on the symbols and labeling conventions used in the guide. Different sections of the machine will be represented by specific shapes or lines, each corresponding to a particular component. Familiarizing yourself with these symbols ensures that you can easily navigate the diagram and find the part you need.

Additionally, pay attention to the flow of the diagram. It often follows a logical sequence, showing how each part connects and operates within the larger system. Understanding this flow helps predict how failures might affect other components and guides you in making the right repairs. With practice, reading these guides becomes an invaluable skill for any operator or technician working with heavy machinery.

Common Repairs with John Deere 214 Parts

Frequent maintenance and repairs are essential for the longevity of any machine. Over time, certain components may wear down due to regular use, requiring replacement or adjustment. Recognizing the most common issues allows operators to anticipate and address potential problems before they lead to significant downtime.

One of the most common repairs involves addressing mechanical failures in key systems, such as the drivetrain or engine components. These parts may require frequent inspections to ensure smooth operation. Regular maintenance of the cooling and lubrication systems is also critical to avoid overheating and prevent costly damage.

Another frequent issue is the replacement of consumable components such as belts, filters, and seals. These items naturally degrade with use and should be replaced as part of routine upkeep. By staying on top of these common repairs, operators can keep equipment in optimal condition and reduce the risk of unexpected breakdowns.