When it comes to maintaining and repairing your vacuum, knowing the structure and individual elements is crucial. A clear view of how everything fits together helps ensure proper functionality and longevity of the device. By understanding each section, you can make informed decisions about replacement or maintenance needs.

In this guide, we will explore how to interpret a detailed layout of a vacuum cleaner’s internal parts. This will include tips on identifying key components, understanding their functions, and learning how to troubleshoot common issues based on the assembly. With this knowledge, users can manage their cleaning equipment more effectively and avoid costly repairs.

Whether you’re a professional technician or a homeowner, this knowledge can be extremely valuable. Understanding how the pieces interact ensures that each part works in harmony, preventing damage and optimizing performance.

Understanding Vacuum Cleaner Components

Every vacuum cleaner consists of several essential elements that work together to ensure efficient cleaning. These components play a key role in the overall performance of the device. Understanding how each part contributes to the machine’s function allows for better maintenance and troubleshooting.

Key Internal Elements

The heart of the vacuum lies in its motor, which powers the suction mechanism. Coupled with the filtration system, the motor ensures that dirt and debris are efficiently picked up and contained. The housing, which encases all these elements, provides the structure and durability required for the machine to withstand everyday use.

Accessory Attachments and Their Functions

In addition to the core components, various attachments enhance the vacuum’s versatility. These include specialized brushes, extension hoses, and other tools that help tackle different surfaces and cleaning tasks. Understanding the function of each accessory is vital to ensure they are used correctly and effectively.

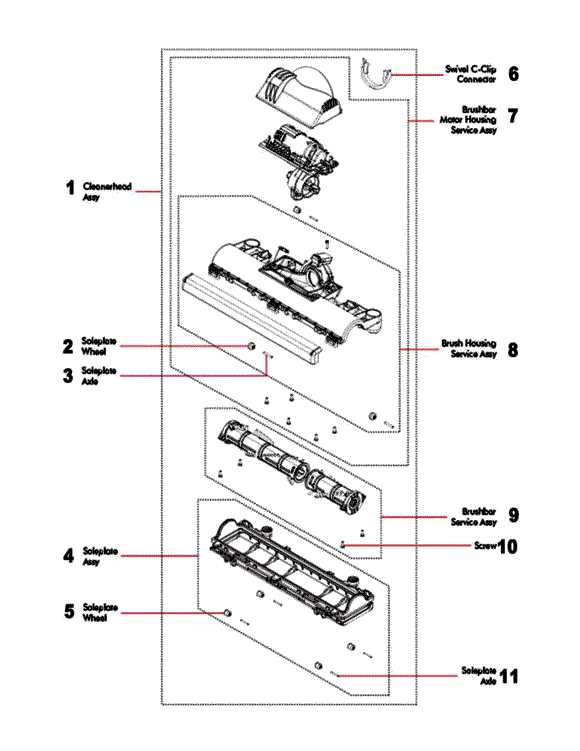

Identifying Key Parts in the Diagram

To effectively understand how a vacuum operates, it’s essential to recognize the critical components that make up the structure. A visual representation can significantly help in pinpointing where each element fits and how it interacts with others within the machine.

Recognizing Core Functional Elements

At the core, the motor is the driving force behind the cleaning performance. Often depicted centrally, it connects to the suction system and is responsible for drawing in dirt. The filtration system, which traps fine particles, is usually placed near the exhaust, ensuring clean air is expelled back into the room.

Understanding Additional Components

Other significant features include the brush bar, which is typically located near the floor head, and the dust canister that stores debris. These accessories are critical for ensuring the vacuum’s efficiency, and their proper positioning is vital for optimal functionality. Identifying their placement on a visual layout ensures the machine operates as intended.

How to Use the Vacuum Component Layout

Understanding how to read a visual layout of a vacuum cleaner’s structure is essential for effective maintenance and repair. By knowing how to interpret each section, you can identify specific areas that need attention and understand the role of each component.

Step-by-Step Interpretation

Start by familiarizing yourself with the overall layout, focusing on the major sections such as the motor, suction system, and filters. Each part will be labeled clearly, helping you trace the connections between them. Use this reference when planning repairs or replacements to ensure proper handling of the device’s internal elements.

Utilizing the Layout for Maintenance

Once you’re familiar with the individual parts, you can use the visual guide to help with routine maintenance. Check for wear and tear in components like the filter or brush bar, and ensure that parts are correctly aligned for optimal performance. By following the layout, you’ll be able to address any issues effectively without causing damage to the machine.