Knowing the individual elements of a complex machine is essential for proper maintenance and repair. This knowledge helps in identifying issues, replacing faulty parts, and ensuring the system operates smoothly. A detailed map of these components serves as a useful guide for anyone working with the equipment.

By examining the layout and connections between different sections, users can gain a clear understanding of how the entire mechanism functions. Recognizing each component’s role allows for better decision-making during troubleshooting and enhances the overall efficiency of operations.

Maintenance experts and technicians rely on such resources to streamline their work, making repairs faster and more accurate. With the right visual guide, even those with minimal experience can follow clear instructions and perform tasks confidently.

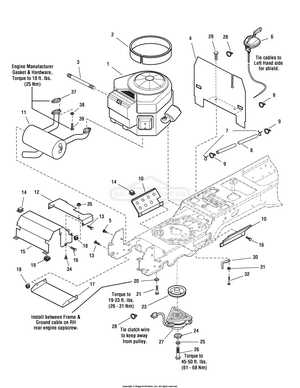

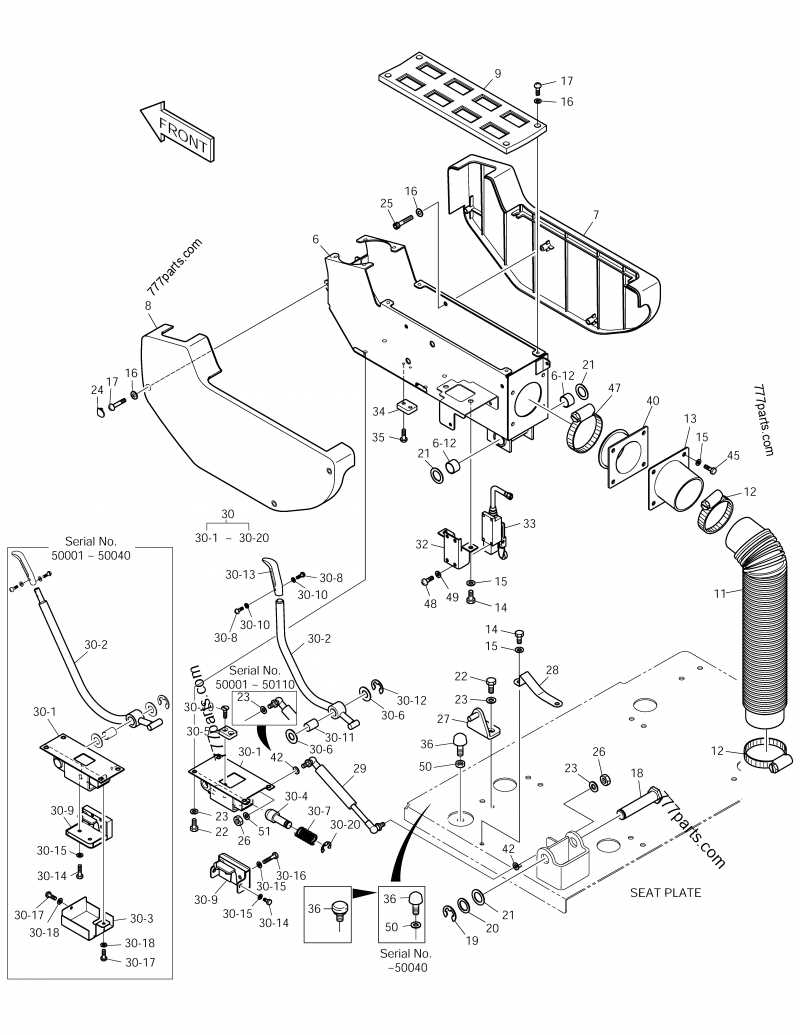

Dyt4000 Parts Breakdown

Understanding the structure of any machinery involves analyzing its different sections and how they interact with each other. Each element plays a crucial role in ensuring the system functions properly, and recognizing their positions and connections is key to effective maintenance and troubleshooting.

In this section, we will explore the key components and their functions within the system. The different sections are designed to work together seamlessly, and each part contributes to the overall performance. Knowing where each component is located helps in diagnosing issues and planning repairs.

By breaking down the machine into individual sections, users can gain a deeper insight into its operation. This understanding allows for quicker identification of potential problems and more efficient solutions when performing routine maintenance or repairs.

Understanding Key Components in the Diagram

Identifying the main elements of any complex system is crucial for effective management and repair. Each section serves a distinct purpose, and understanding these roles allows for smoother maintenance and quicker troubleshooting. Having a clear overview of how everything fits together is essential for any technician or operator.

Critical Sections and Their Functions

Each section plays a specific role in the system’s overall operation. Understanding these roles ensures that users can easily identify which components need attention during maintenance. Whether it’s a mechanical part or an electrical system, knowing where each piece fits helps in organizing repairs more efficiently.

Interconnections and Workflow

The interaction between different components is what drives the entire system. These connections determine how effectively each part performs its function. By recognizing how one section impacts the others, users can more easily diagnose faults and address them promptly without disrupting the overall workflow.

How to Use the Dyt4000 Diagram for Repairs

Using a visual representation of a system’s structure is essential for efficient repair work. By referring to such a resource, technicians can locate problematic areas, identify specific parts that need attention, and carry out tasks with precision. A clear map of the machine’s layout is the key to performing repairs accurately and quickly.

Start by analyzing the layout to understand the position of each section. This helps in narrowing down the source of any issue. Once the faulty part is identified, the next step is to check its connection to other components, ensuring that everything is functioning in unison. Having a clear reference makes it easier to follow the repair process without skipping important steps.

When working with intricate systems, always refer back to the layout to avoid confusion. This will not only save time but also reduce the chances of making errors during repairs. Using this approach helps technicians stay organized and ensures that all tasks are completed efficiently.