For effective operation and maintenance, it is essential to have a clear understanding of the inner workings of any heavy machinery. By breaking down the key components and their relationships, users can identify areas that require attention or potential upgrades. A detailed overview of these elements ensures smoother operations and can save time and costs in the long run.

In this section, we will explore how to navigate the detailed schematics of complex machinery. These visual guides serve as invaluable resources, offering insights into the specific parts and their functions. Whether you are a mechanic or a regular user, knowing where each piece fits within the system can be crucial for troubleshooting or regular upkeep.

Having a strong grasp of the machine’s framework can also improve safety and extend the lifespan of your equipment. Proper identification and care of each segment contribute to the overall performance and reliability, preventing unexpected breakdowns and costly repairs. Through this guide, you will gain the knowledge needed to ensure the long-term efficiency of your machinery.

Understanding the Key Machine Components

To ensure optimal performance, it is important to familiarize yourself with the core elements that make up any complex machinery. Each component plays a vital role in the machine’s function, and understanding their purpose allows for better maintenance and troubleshooting. By recognizing how these individual parts interact, users can easily identify potential issues and address them efficiently.

Critical Elements of the System

Every machine relies on a range of components, each designed for a specific function. From the engine and hydraulic systems to the structural framework, knowing the purpose of each part helps in proper care and operation. A well-maintained structure ensures that each segment operates smoothly, contributing to the overall reliability and efficiency of the equipment.

Identifying Parts for Efficient Repairs

Properly identifying each element is essential when performing repairs or upgrades. With an in-depth understanding of how each part fits into the larger system, users can quickly pinpoint which component requires attention. This knowledge can significantly reduce downtime and repair costs, helping to keep the machinery running smoothly for longer periods.

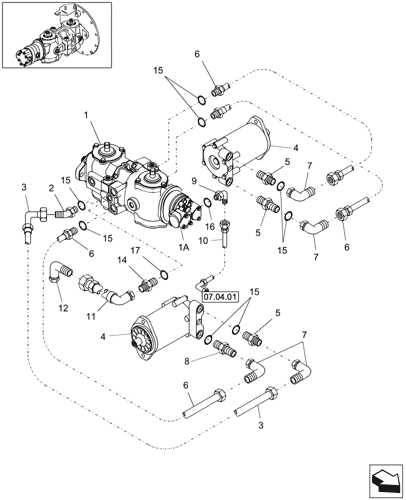

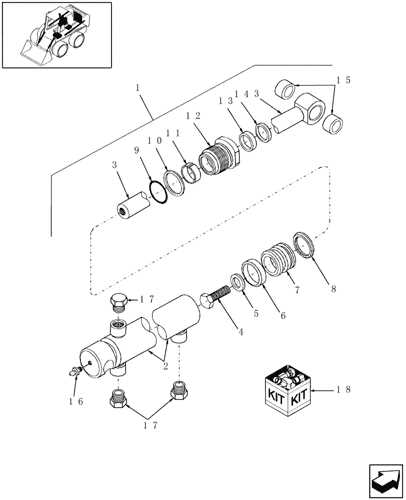

How to Read the Equipment Schematic

Understanding how to interpret visual guides is crucial for efficient maintenance and repair. These schematics provide a detailed view of the machine’s internal components and their interconnections. With the right approach, users can quickly identify specific parts, their functions, and how they work together within the system.

Decoding Symbols and Labels

Each schematic uses a combination of symbols and labels to represent various components. Familiarizing yourself with these markings will enable you to understand the different sections and their relationships. Key elements to look for include:

- Component Labels: These indicate the name or function of each part.

- Connection Lines: Show how parts are linked, often representing mechanical or hydraulic connections.

- Reference Numbers: Used to identify parts for easy lookup in manuals or for ordering replacements.

Using the Schematic for Troubleshooting

When it comes to identifying problems, a schematic is an invaluable tool. To effectively troubleshoot, follow these steps:

- Identify the specific area of the system that is malfunctioning.

- Locate the corresponding section on the schematic.

- Check the related components for potential issues like wear or damage.

- Use the reference numbers to find replacement parts or further details.

By mastering the reading of these visual guides, you can ensure more accurate repairs and reduce the chances of missing underlying issues. With practice, interpreting schematics becomes an essential skill for maintaining the efficiency of the machinery.

Key Elements for Maintenance and Repair

For effective upkeep and longevity of heavy machinery, it’s important to focus on the core components that require regular attention. These key elements are essential for maintaining proper function and performance. Understanding the critical areas that need periodic inspection ensures that any potential issues are addressed promptly, preventing larger problems from arising.

Among the most vital components for maintenance are the engine, hydraulic system, and structural framework. Each of these systems plays a unique role in the overall operation, and neglecting them can lead to decreased efficiency or even breakdowns. Routine checks and timely repairs of these areas can extend the life of the equipment and improve its reliability.

In addition to the primary systems, certain smaller components such as filters, seals, and hoses should not be overlooked. These parts play a critical role in keeping the machine running smoothly. Regular replacement and maintenance of these items ensure that the larger systems remain undisturbed and function at their optimal levels.