Maintaining your cleaning equipment in top condition is crucial for ensuring optimal performance and longevity. Understanding the internal structure and components is the first step in diagnosing issues and carrying out effective repairs. Whether you are troubleshooting or replacing parts, knowledge of how each component functions together is essential.

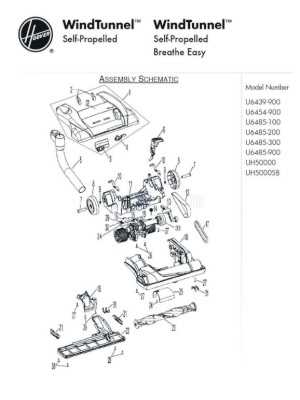

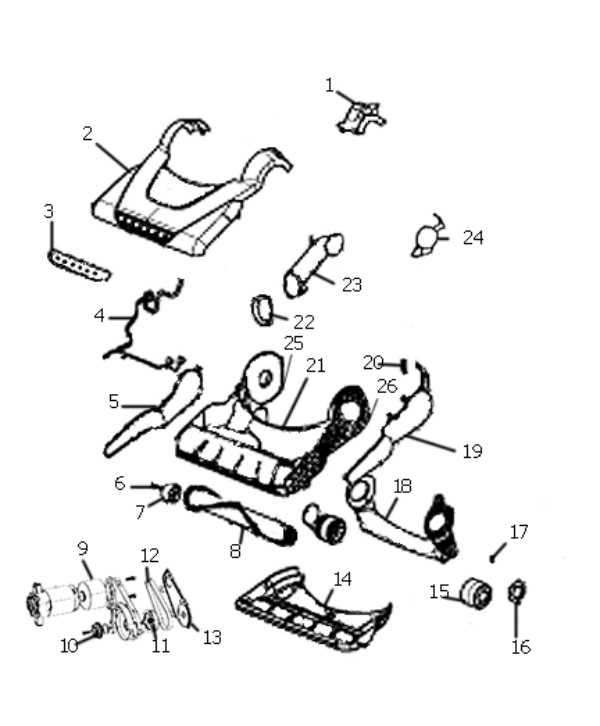

Knowing how to identify and fix problems allows you to make informed decisions about necessary replacements or repairs. Many models have unique layouts, making it important to refer to visual aids that show where each element fits and how it interacts with others. By mastering this, you can handle most maintenance tasks independently.

This guide aims to provide detailed insights into the key components of household cleaning machines. By following these instructions, you can easily spot what needs attention, extend the life of your equipment, and avoid unnecessary service costs.

Understanding Household Cleaner Components

Every cleaning machine is made up of various interconnected elements that work together to provide effective performance. Recognizing how these parts function individually and together is essential for both maintenance and troubleshooting. Knowing the role of each component helps in identifying issues and streamlining repairs.

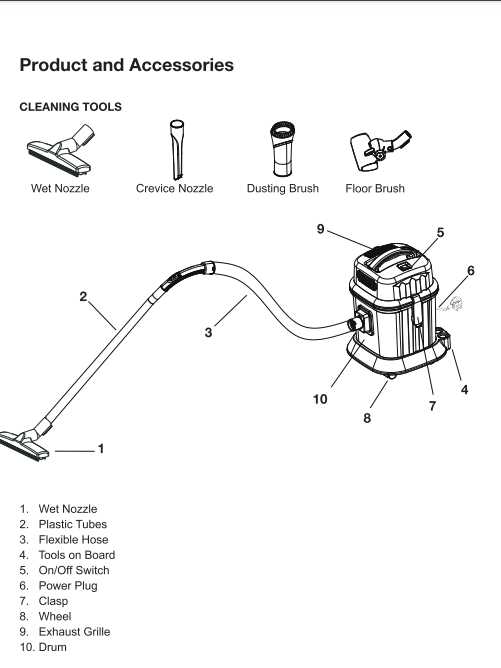

The key components of these devices include the motor, brushes, filters, and hoses. Each of these elements contributes to the overall efficiency and cleaning power. When one part malfunctions, it can affect the entire system’s functionality. For instance, a damaged motor can reduce suction, while clogged filters can lead to poor air flow.

Understanding the layout of these components is essential for any repair or maintenance process. Visualizing their arrangement allows for a clearer understanding of their interactions, making it easier to identify where issues may arise and how to address them.

How to Identify Vacuum Parts by Model

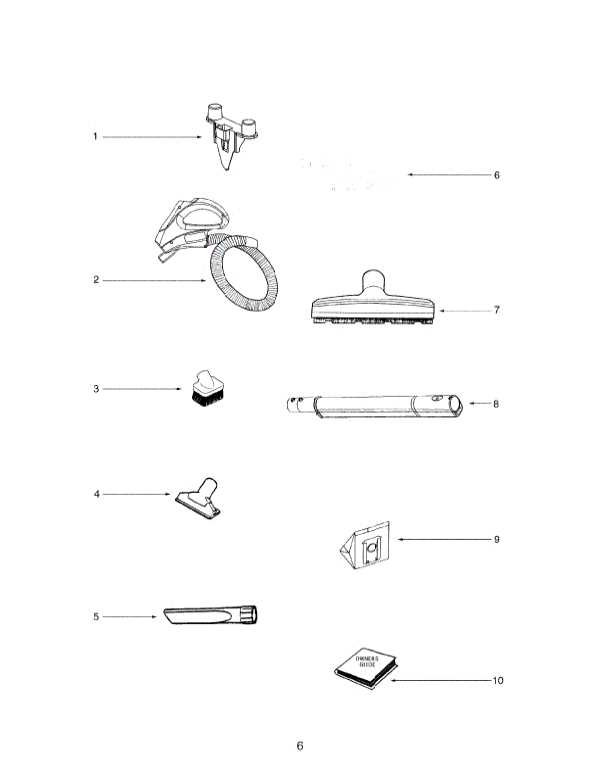

Recognizing the components of your cleaning machine can be a straightforward process once you know how to match them with the correct model. Identifying specific elements becomes easier with the help of a model number and a basic understanding of each part’s function.

Start by locating the model number on your device. Typically, it is found on a label or sticker located on the base or back of the machine. Once you have the model number, use it to access the appropriate resources for that particular model.

- Search for the user manual or online documentation related to your model number. Most manufacturers provide a detailed list of components and their functions.

- Check the manufacturer’s website or third-party repair sites for exploded views or visual guides that clearly show how each part is arranged.

- Consider taking pictures of the components when disassembling the unit. This can help you confirm the parts and ensure accurate reassembly later.

Once you have visual references, it will be easier to recognize parts, order replacements, and perform any necessary repairs. This methodical approach ensures that you’re always working with the right components for your specific model, saving both time and effort.

Common Repairs Using Diagrams

When a cleaning machine malfunctions, knowing how to troubleshoot and repair it is essential to avoid costly service calls. Diagrams can be invaluable tools for identifying where issues lie and for guiding you through common repairs. By understanding the layout of components, you can efficiently replace or fix broken parts, restoring functionality.

One frequent issue is a loss of suction, which may be caused by blockages in the hose or a damaged motor. A visual guide can help you locate and clean the hose or check for motor issues without the need for expert assistance.

Another common repair involves replacing filters or brush rollers. Over time, these components can wear out or become clogged, reducing efficiency. Diagrams will clearly show how to disassemble the unit and replace the worn parts, making this repair easy to manage at home.

By referring to these visual aids, you can make informed decisions about which components to repair or replace, ensuring your equipment stays in good working condition for longer periods of time.