Maintaining your chainsaw in top condition requires a clear understanding of its internal structure and key components. Whether you are a professional or an enthusiast, knowing how each part works together can greatly improve your ability to troubleshoot and perform repairs. A detailed guide to these elements helps ensure smooth operation and longevity of the tool.

Proper maintenance is essential for avoiding costly repairs and ensuring efficiency during use. By familiarizing yourself with the essential components of your equipment, you can identify potential issues early on and replace faulty parts when necessary. This guide will help you navigate through the various sections of your chainsaw, highlighting the most common components and their functions.

Learning how to interpret a parts map allows you to accurately pinpoint and replace malfunctioning pieces. With a bit of knowledge and the right resources, you can ensure your chainsaw continues to perform at its best for years to come.

Understanding Chainsaw Components

To effectively maintain and repair your tool, it’s crucial to understand how each internal element contributes to overall functionality. Each component works in harmony to ensure smooth operation, and knowing how they interact allows you to identify issues early. From the engine to the chain assembly, all parts play a vital role in performance and longevity.

Key Components and Their Functions

The engine is the heart of your chainsaw, responsible for converting fuel into power. The ignition system ensures the engine starts smoothly, while the fuel system delivers the necessary energy. The carburetor regulates fuel flow to the engine, and the air filter keeps debris from entering and causing damage. Other essential elements, like the chain brake and the clutch, provide safety and control during use.

Common Issues and Solutions

Understanding the function of each part also helps in diagnosing common problems. If the engine struggles to start, the ignition system or fuel delivery might be at fault. A worn-out chain or tensioning mechanism could result in reduced cutting efficiency. Regular inspection of each component ensures potential issues are addressed before they affect performance.

How to Read the Chainsaw Component Map

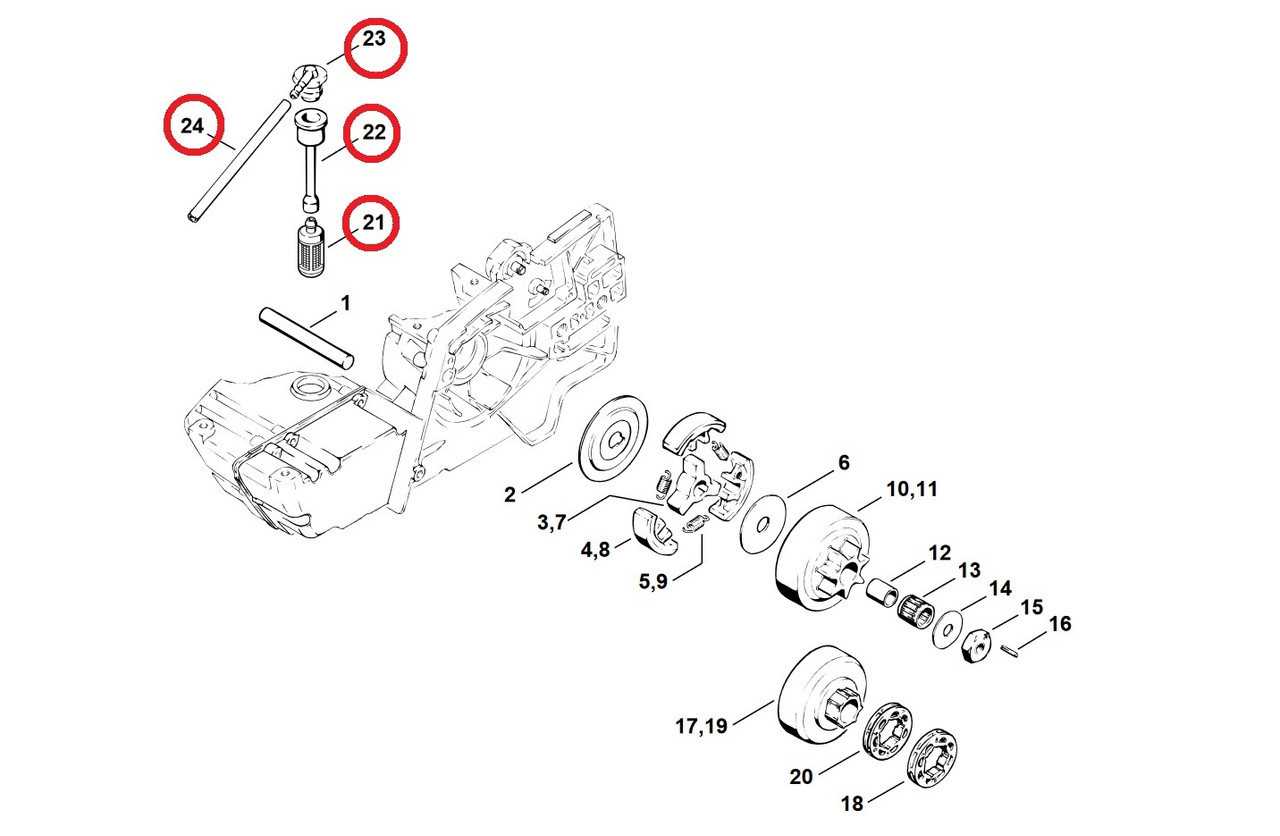

Understanding how to interpret a component map is essential for effective maintenance and repair. These visual guides provide a clear overview of the tool’s internal structure, helping you identify and locate specific parts quickly. Knowing how to read this map will allow you to troubleshoot issues and replace worn-out elements with precision.

Identifying Key Sections

The map typically divides the tool into various sections, each corresponding to a specific system or mechanism. The engine area will be labeled separately from the chain assembly or the fuel system. Look for numbered sections or labeled parts that indicate where each component is located within the overall structure. This makes it easier to find the exact piece you need to repair or replace.

Understanding Part Numbers and Labels

Each part will have a corresponding number or label that connects it to a specific reference in the parts catalog. The map will often provide a legend or list with detailed information about these numbers, including descriptions and the compatible model. By cross-referencing these details, you can ensure that you are selecting the correct replacement components for your tool.

Common Repair Issues for Chainsaws

Chainsaws are robust tools, but like any mechanical equipment, they can experience issues over time. Understanding the most common problems helps you identify and address them promptly, reducing downtime and maintaining efficiency. From engine troubles to chain-related concerns, recognizing the symptoms can save you both time and money on repairs.

Engine Not Starting

If your chainsaw’s engine fails to start, it is usually related to the ignition system, fuel delivery, or spark plug. A clogged fuel filter or improper fuel mixture can prevent the engine from receiving the right amount of power. Similarly, a damaged spark plug or faulty ignition coil can prevent the engine from firing. Regularly checking these components can help you quickly diagnose the issue and get the tool running again.

Reduced Cutting Efficiency

When a chainsaw isn’t cutting properly, the issue often lies with the chain assembly or tensioning system. A dull or worn-out chain can cause inefficient cutting, while improper chain tension may affect performance. Regularly sharpening the chain and ensuring the correct tension can prevent this issue. Additionally, check for debris buildup around the chain brake or guide bar, which can also hinder the tool’s effectiveness.