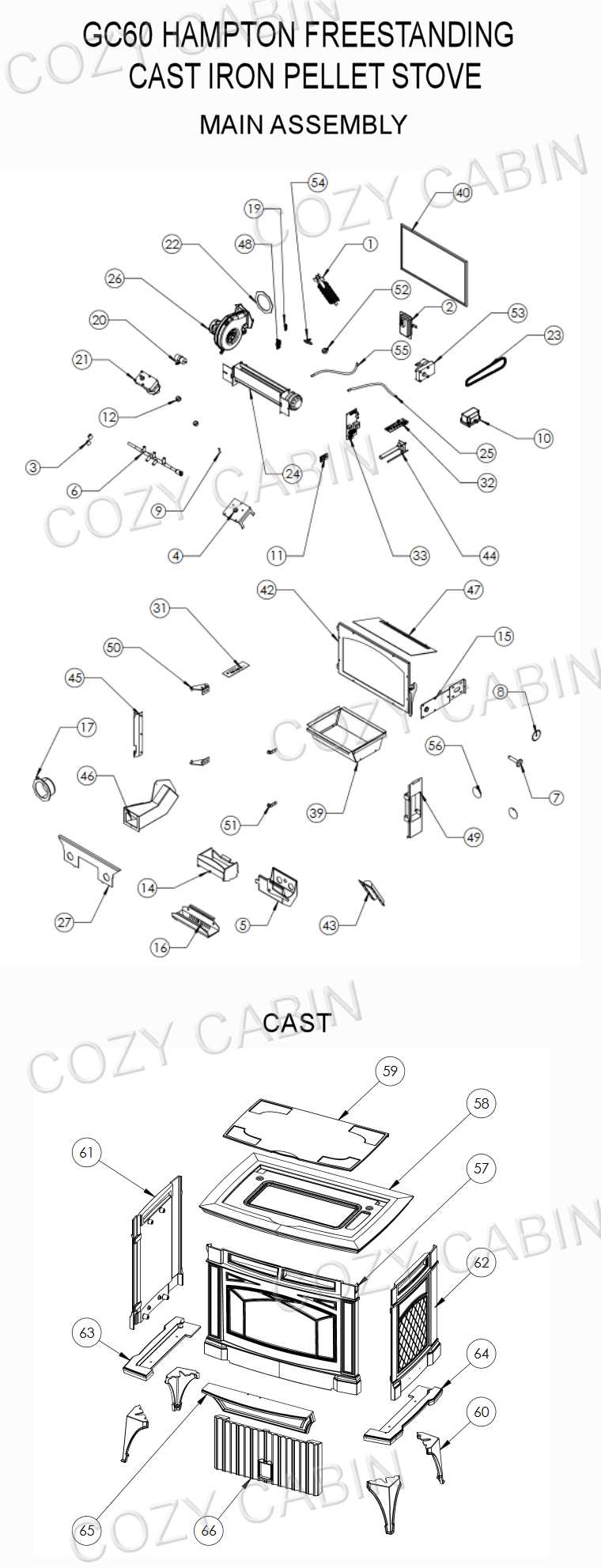

Maintaining an efficient heating system requires knowledge of its internal elements and how they function together. Identifying and understanding these components can significantly improve troubleshooting and repair efforts. Each component plays a vital role in ensuring smooth operation, and knowing how they interact is essential for proper maintenance.

In this section, we will explore the key elements of a heating unit, providing an overview of their positions and functions. By understanding the layout and mechanisms, you can easily spot potential issues and take the necessary steps to resolve them. Whether you’re a seasoned technician or a DIY enthusiast, having a clear view of these critical parts is crucial for successful operation.

Understanding Heater Components

To ensure optimal performance, it is important to familiarize yourself with the key elements of any heating unit. These components work together to generate and distribute warmth efficiently throughout the space. By understanding their roles, you can better identify issues and ensure smooth operation.

The essential elements of a heating system include the burner assembly, combustion fan, fuel delivery system, and the heat exchanger. Each part has a specific function, whether it’s igniting the fuel, circulating air, or controlling the flow of energy. Recognizing how these components interact helps with diagnosing problems and performing maintenance tasks effectively.

Familiarity with the unit’s layout will make troubleshooting much easier. Knowing where each component is located and understanding its purpose will help you pinpoint the source of any malfunction. Regular inspection and maintenance of these critical elements will keep the system running efficiently and extend its lifespan.

How to Read a Heater System Layout

Interpreting the layout of a heating system is essential for understanding its internal structure and functionality. These illustrations serve as a map, showing the arrangement of all critical components and how they interact. By learning to read these layouts, you can quickly locate specific elements, identify potential issues, and carry out repairs or maintenance tasks more efficiently.

The key to reading such a layout is focusing on symbols and labels. Typically, each component will be represented by a specific icon or shape, with corresponding annotations to explain its function and position. Pay attention to any color-coding or numbering systems, which can help indicate the flow of air, fuel, or electricity within the system.

Additionally, many layouts include reference notes that explain connections between components. These notes provide helpful information about the operational relationship between various parts, such as airflow direction, power connections, and safety features. Being able to understand these details will significantly improve your troubleshooting skills and enhance your overall maintenance knowledge.

Common Issues and Part Replacements

Heating systems, like any complex machinery, are susceptible to wear and tear over time. Understanding common malfunctions can help identify the need for replacements or repairs before they become major problems. Knowing which components are likely to fail and recognizing the symptoms of a malfunction are key to maintaining system efficiency and longevity.

One of the most common issues is a malfunctioning ignition system. If the unit fails to start or ignite properly, it could indicate a problem with the igniter or electrical connections. Another frequent issue is poor airflow, which may be caused by a clogged fan, blocked vents, or a malfunctioning blower motor. These problems can reduce the heating efficiency and increase energy consumption.

When components wear out or stop functioning, replacing them with high-quality, compatible parts is essential. Regularly inspecting key elements such as the combustion fan, fuel delivery system, and safety sensors will help ensure the system remains in optimal working condition. Timely part replacements prevent further damage and enhance the overall performance of the unit.