In this section, we explore the essential elements that make up complex machinery systems. Understanding the relationship between these components is crucial for effective maintenance, troubleshooting, and overall system performance. By breaking down the components and their roles, users can gain a deeper insight into the functioning of the entire setup.

Every system is made up of interconnected pieces, each contributing to the smooth operation of the whole. Proper identification and understanding of these individual units can help optimize their use, reduce errors, and streamline repairs. Whether you are a professional technician or a hobbyist, knowledge of these elements enhances efficiency and reduces downtime.

Detailed exploration of each component’s purpose, function, and connectivity provides a comprehensive understanding that is indispensable for anyone involved in system management or repair. A structured view of these elements can also assist in predicting potential issues and planning preventive measures.

Understanding the System Configuration

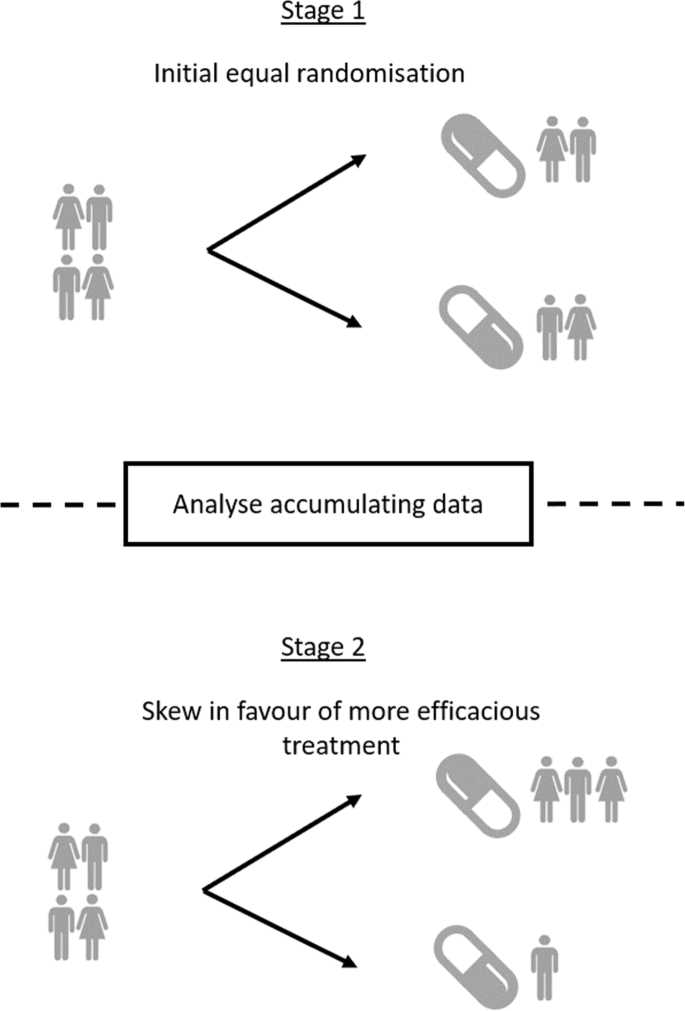

In this section, we delve into the structure and functionality of a specialized machinery system designed for optimal performance. The system consists of various interconnected elements, each playing a significant role in achieving the desired results. Gaining a thorough understanding of how these components work together is essential for ensuring smooth operation and minimizing the risk of malfunctions.

The key to mastering the system lies in recognizing the interactions between its individual units. Each part contributes to the overall efficiency, whether it’s handling specific tasks or supporting the primary functions. Familiarizing oneself with this configuration is essential for troubleshooting and ensuring that all units operate in harmony, making the system reliable and effective for long-term use.

Key Components of the System

The system is composed of several critical elements that work in unison to ensure its proper functionality. Each unit has a specific role, contributing to the overall operation and stability of the machinery. Understanding these key components is vital for maintaining performance and resolving any potential issues that may arise during usage.

Critical components include those that handle core operations, support vital processes, and enable smooth interaction between various units. Knowing the purpose and function of each part allows for more efficient troubleshooting and effective management of the system. When all units are in sync, the system operates at its best, providing consistent results over time.

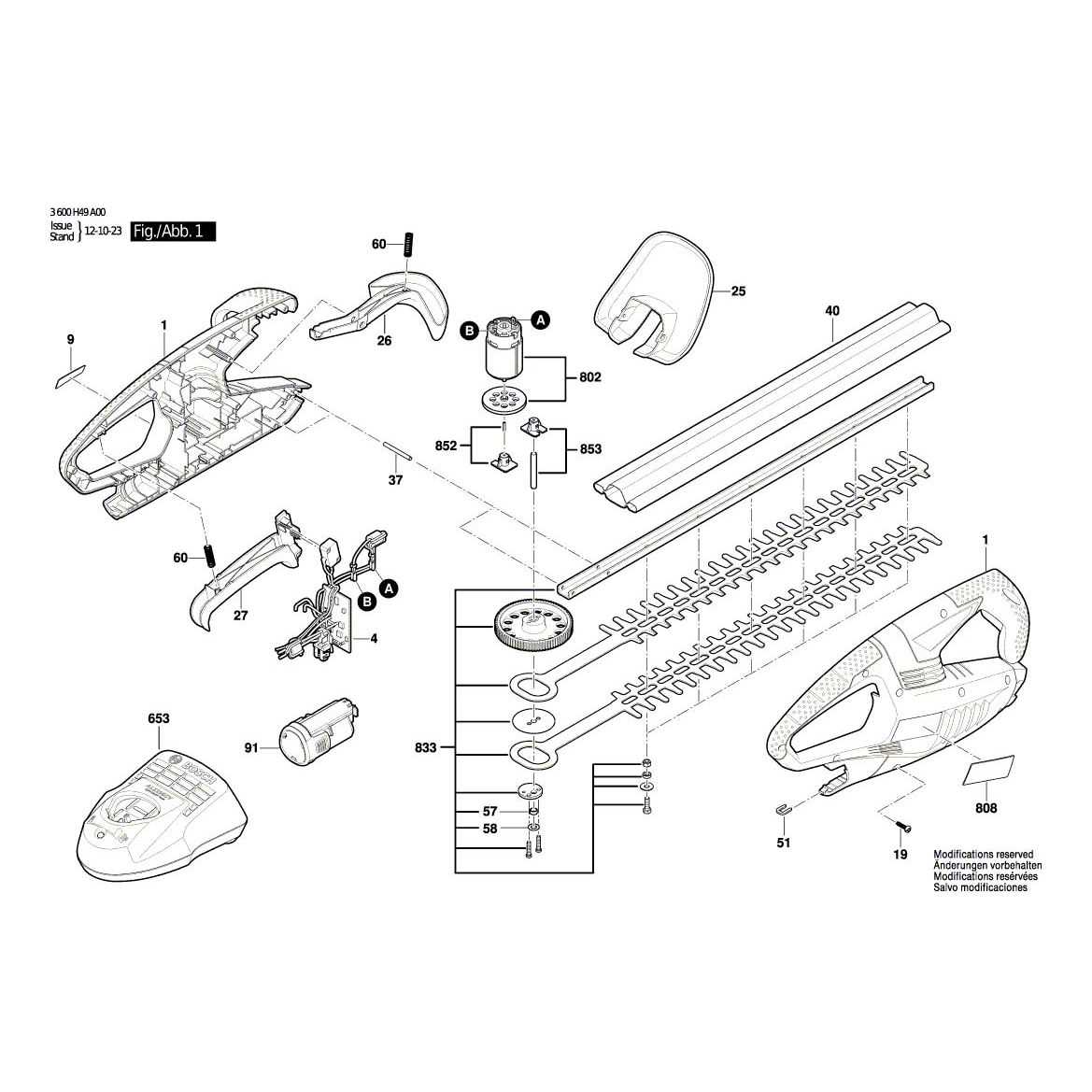

How to Use the Component Layout Effectively

Utilizing a component layout requires understanding how to read and interpret the visual representation of the system’s structure. A clear and accurate layout serves as a guide to identify and locate each element, making it an essential tool for maintenance, repairs, and upgrades. The more familiar you are with the layout, the more efficiently you can navigate and resolve potential issues within the system.

Steps for Effective Use

Start by familiarizing yourself with the overall structure and the positioning of individual units within the layout. Once you understand the general setup, focus on the details of each section. Pay attention to labels and any distinguishing features that indicate specific parts or connections. This will allow you to quickly identify any parts that need attention or replacement.

Tips for Accuracy and Efficiency

Carefully cross-reference the layout with the physical system to ensure everything matches up correctly. Using this approach helps prevent mistakes and saves time during maintenance. Regularly consulting the layout during repairs or inspections will improve your efficiency and accuracy, ensuring that each component is correctly addressed when necessary.