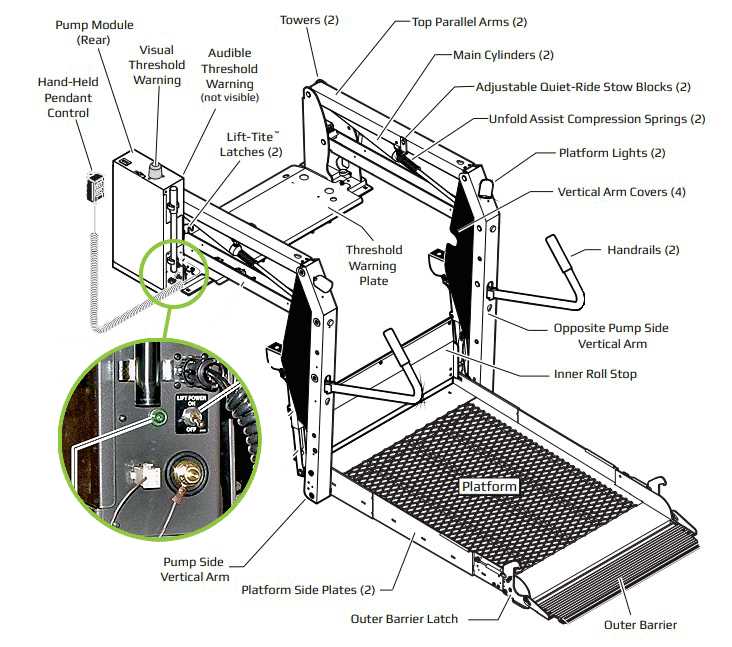

For efficient operation and long-lasting performance, it is essential to understand the key elements that make up mobility devices. Knowing how each part works together ensures smoother usage and easier troubleshooting when issues arise. This knowledge empowers users to make informed decisions regarding maintenance and repairs, ultimately prolonging the lifespan of their equipment.

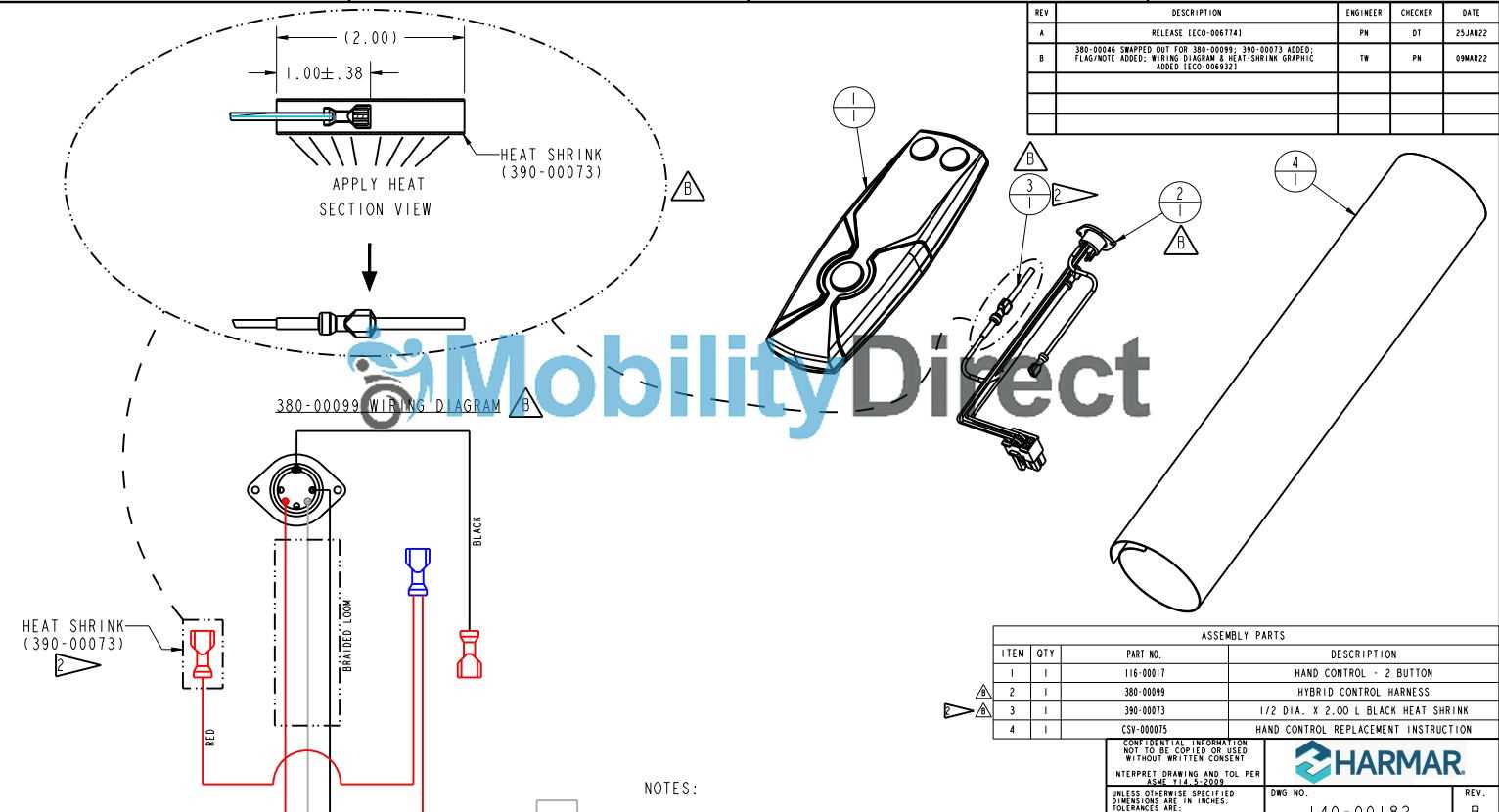

Detailed schematics provide a visual representation of how all components fit together, offering insight into their functions and interconnections. Having access to such resources simplifies the repair process and helps users recognize potential issues before they escalate.

Whether you’re an owner or a technician, being familiar with these resources and how to interpret them can significantly reduce downtime and improve overall performance. Proper maintenance and timely repairs are crucial in keeping the device running at its best.

Understanding the Mobility Device Components

Knowing the essential elements that comprise mobility equipment is crucial for ensuring smooth operation and addressing issues promptly. Each component has a specific function that contributes to the overall performance. Gaining a deeper understanding of how these parts interact allows for better care, maintenance, and troubleshooting.

Key Functional Elements

- Base structure: This provides stability and supports the other components. A strong foundation ensures that the device operates efficiently and securely.

- Drive mechanism: Responsible for moving the device, it includes motors or mechanical systems that provide movement in various directions.

- Support arm or platform: The part designed to provide additional support, often adjustable to meet user needs.

- Control system: This allows users to operate and manage the equipment’s functions, from movement to safety settings.

Importance of Proper Maintenance

Regular inspection of each component is essential to avoid unexpected failures. Over time, wear and tear can affect performance, leading to potential safety risks. By familiarizing yourself with the function and location of each element, you can quickly identify issues and perform basic repairs when necessary.

- Visual checks: Ensure there are no visible signs of damage, such as cracks or loose parts.

- Functionality tests: Periodically test each function to ensure everything is operating smoothly.

- Lubrication and cleaning: Keep moving parts clean and well-lubricated to extend their lifespan.

How to Read a Mobility Equipment Schematic

Understanding the visual representation of equipment components can significantly enhance your ability to perform repairs and maintenance. These schematics break down the structure into easily identifiable sections, allowing users to pinpoint where each part fits and functions within the system. By becoming familiar with these visuals, you can troubleshoot effectively and carry out repairs with confidence.

Visual aids provide a detailed layout of all the essential components and their interactions. The key to reading these illustrations is recognizing symbols and understanding the relationships between parts. Each part is typically labeled with numbers or letters that correspond to descriptions in accompanying manuals or lists.

Important aspects to focus on:

- Component labels: Ensure you can identify each element by its label. This will help you match it to the corresponding part number or description in a manual.

- Connections: Pay attention to how parts are linked. Arrows or lines may indicate how different components work together.

- Scale: The schematic might show a scaled version of parts, so understanding the relative sizes can help in identifying the correct component for repairs.

Once you are familiar with the symbols and structure, it becomes easier to follow along with the schematic and make accurate assessments during maintenance. Regular practice with these visual tools will build your confidence in troubleshooting and repairing the equipment as needed.

Common Issues and Repair Tips for Mobility Devices

Like any mechanical equipment, mobility devices can experience problems over time. Recognizing common issues early and knowing how to address them can prevent more serious damage and extend the lifespan of the system. Regular maintenance and quick fixes are key to ensuring smooth and reliable operation.

One of the most common problems is difficulty with movement, often caused by wear in the drive system or issues with electrical components. If the device struggles to move or respond to controls, checking for loose connections or low power levels should be the first step.

Typical issues and solutions:

- Power failure: Ensure the battery is fully charged, and check for damaged wires or disconnected terminals. If the battery seems weak, it might need to be replaced.

- Unresponsive controls: Inspect the control system for any faults, such as faulty buttons or wiring. Cleaning the control panel can often resolve minor issues.

- Unstable movement: Check for issues in the support mechanism. Tighten any loose parts, and ensure there is no debris or obstruction in the movement path.

By addressing these problems promptly and knowing when to replace parts or seek professional help, you can keep the device running smoothly and avoid unnecessary repairs. Regular inspections and preventative care are essential to avoid major malfunctions.