Maintaining a chainsaw involves understanding its individual components and how they interact. Knowing where each part fits and functions is essential for both efficient use and troubleshooting. Whether you’re a professional or a hobbyist, this knowledge can save time and money when repairs or replacements are necessary.

Identifying each piece of the machinery allows for quick assessments and accurate fixes. Knowing the key sections and their purposes helps pinpoint issues before they escalate. With this guide, you’ll be able to visualize the inner workings of the tool, ensuring your equipment runs smoothly.

By mastering the structure of your chainsaw, you gain the confidence to perform regular maintenance and replacements. Understanding how each part contributes to the overall function allows for a longer-lasting tool and improved performance.

Poulan Wild Thing Overview and Components

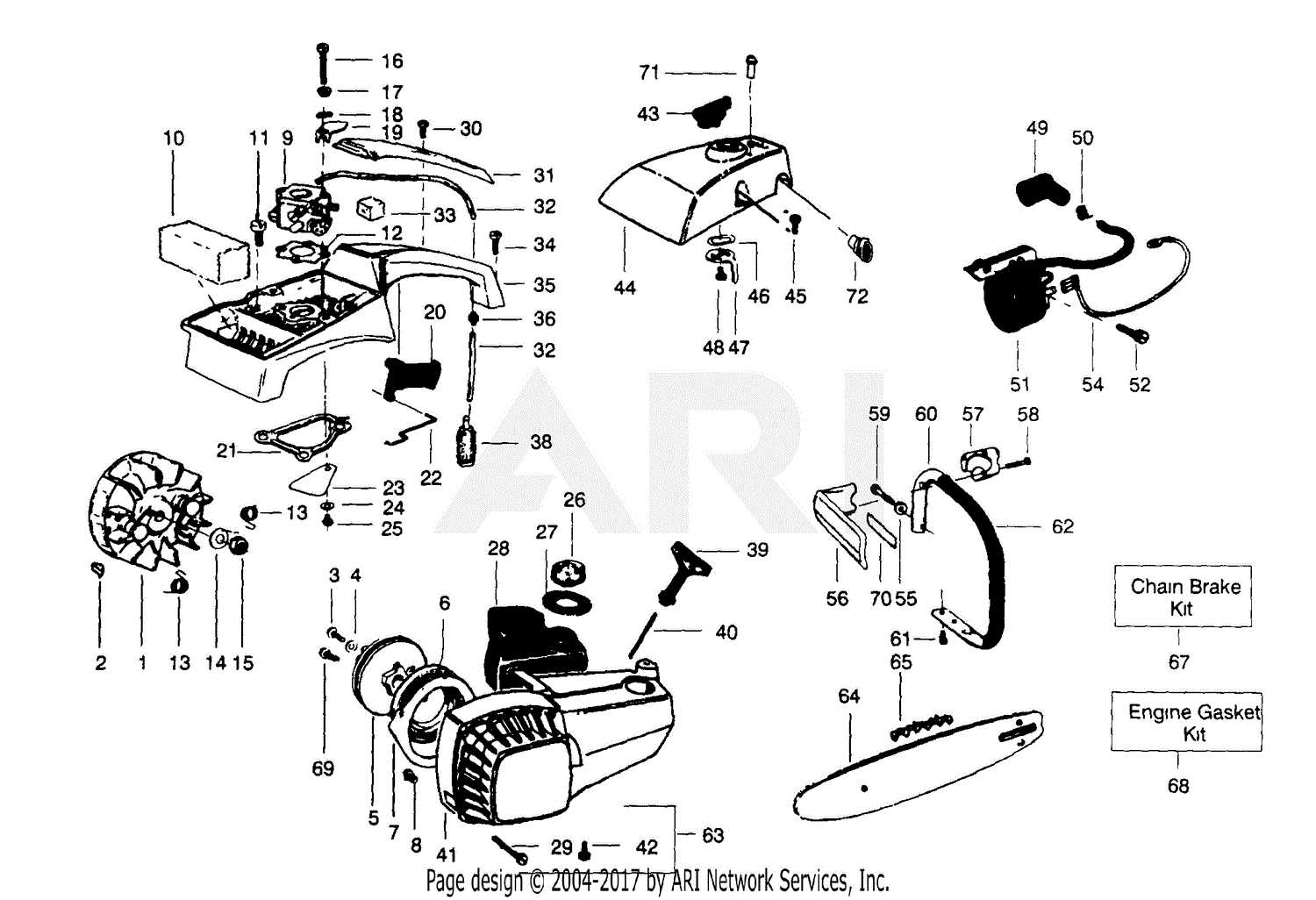

Understanding the core elements of a chainsaw is crucial for efficient maintenance and repair. Each piece plays a role in the overall functionality, contributing to its performance and longevity. Familiarizing yourself with the layout and function of these components ensures that you can handle basic upkeep and repairs without unnecessary complications.

Key Features of the Tool

This chainsaw features a variety of parts that work in unison to provide the cutting power needed for different tasks. The motor, handle, and safety mechanisms are among the most important components, each contributing to the tool’s overall performance. The engine powers the blade, while the safety features protect the user from potential harm.

Commonly Used Components

Several components are vital for the chainsaw to operate effectively. These include the chain brake, air filter, carburetor, and ignition system. Each part ensures that the tool operates efficiently and safely. Understanding their locations and functions helps users spot any issues early, allowing for prompt troubleshooting and part replacement when necessary.

Understanding the Parts Breakdown for Maintenance

Effective upkeep of any chainsaw relies on a clear understanding of its individual components and how they interact. Recognizing the role each element plays allows users to perform routine checks and address issues before they lead to bigger problems. A thorough knowledge of the tool’s structure ensures that any maintenance or repair is carried out with precision, improving the lifespan and performance of the machine.

Critical Components for Regular Care

To maintain smooth operation, certain elements must be inspected and cleaned periodically. These include the engine, carburetor, chain, and filter systems. Each part serves a specific function, and neglecting their care can lead to inefficiency or damage. Regular maintenance involves checking for wear and tear, ensuring all parts are securely in place, and replacing any components that show signs of damage.

How to Spot Potential Issues Early

Familiarity with the tool’s parts allows for quick detection of potential problems. For instance, if the chain becomes loose or the air filter is clogged, performance will degrade. Knowing what to look for and when to take action prevents costly repairs and ensures the tool runs optimally. Keeping an eye on these key components and performing preventive maintenance regularly can avoid significant downtime.

How to Identify and Replace Faulty Parts

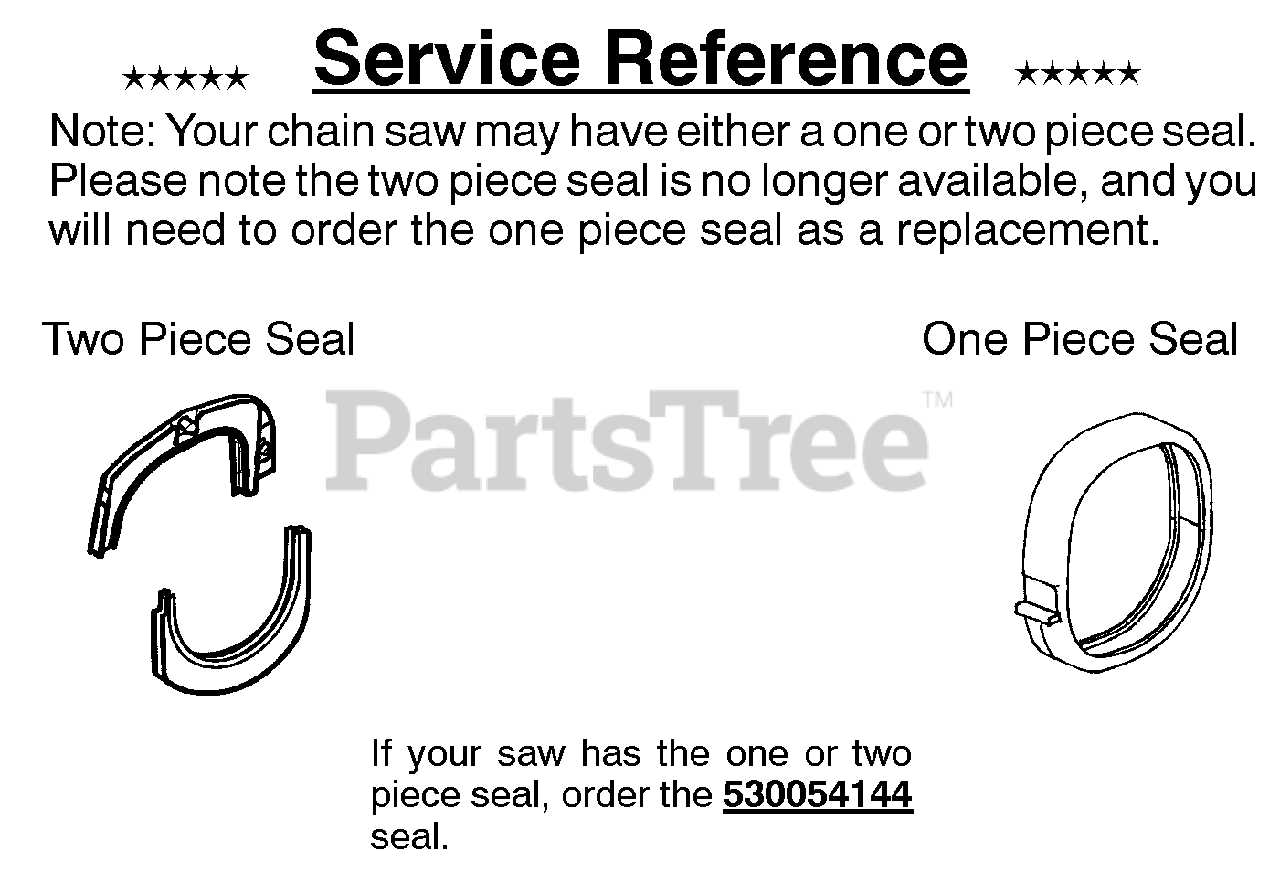

Identifying malfunctioning components is key to keeping your chainsaw running smoothly. Regular inspection allows you to detect worn-out or damaged parts before they affect performance. Whether the tool isn’t starting, is running inefficiently, or is producing unusual sounds, recognizing the issue quickly can prevent further damage and costly repairs. Knowing how to troubleshoot and replace problematic elements will ensure your tool remains in top condition.

Start by assessing the key features of the tool, such as the engine, chain, air filter, and spark plug. Each of these components is critical for optimal performance. If the engine stalls or struggles to start, it could be due to a clogged air filter or a faulty spark plug. A worn-out chain may cause difficulty in cutting, while a malfunctioning carburetor can result in poor fuel efficiency.

Once the faulty component is identified, the replacement process can begin. Many parts are easily replaceable with basic tools and a bit of know-how. Be sure to consult the user manual for specific instructions on how to remove and install each part correctly. For more complex repairs, it may be necessary to seek professional assistance to avoid causing additional damage.