When it comes to maintaining your equipment, understanding its internal structure is crucial. Whether you’re dealing with a handheld machine or larger outdoor equipment, knowing the components helps ensure optimal performance and longevity.

Each model has a unique assembly, and familiarizing yourself with the layout of its parts can simplify troubleshooting and repairs. In this section, we’ll explore the key elements of your equipment and how they interact, offering a clear view of how everything fits together.

By understanding the various sections and components, you can identify wear and tear, replace damaged parts, and maintain your tool with ease. With the right knowledge, you’ll be prepared for any maintenance tasks, ensuring your machine operates at its best.

Understanding the Tool’s Key Components

Having a clear grasp of your equipment’s structure is essential for effective use and maintenance. Recognizing how each part works together ensures smooth operation and helps identify issues before they become major problems.

In any outdoor device, the core parts include the motor, airflow system, and controls. Understanding how these elements interact allows for better performance management and easier troubleshooting when needed. The key is to familiarize yourself with the layout and functionality of each section to maintain efficiency.

Maintenance and repairs can be simplified once you know the arrangement of components. Proper knowledge helps you replace worn-out or malfunctioning elements, ensuring the equipment continues to work properly over time. Staying informed about the machine’s internal workings is an important step in getting the most out of your tool.

Key Components of the Outdoor Equipment

Each piece of outdoor machinery is made up of several critical components that work in unison to ensure proper functionality. Understanding these elements is essential for effective use and maintenance, allowing the user to spot issues quickly and keep the machine running smoothly.

Among the most important sections are the motor, which drives the entire mechanism, and the airflow system, responsible for directing the output efficiently. Other notable parts include the control system, which enables the user to adjust settings, and the housing, which protects the internal mechanisms from wear and environmental elements.

Familiarizing yourself with these key components will provide the knowledge needed for repairs and preventive care. Regular inspection and replacement of worn-out sections can significantly extend the life of your equipment.

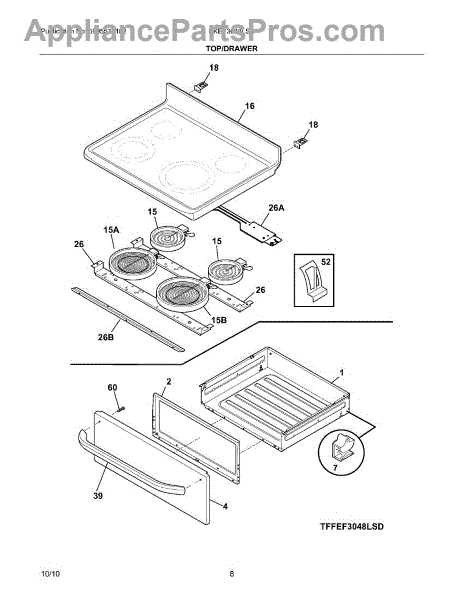

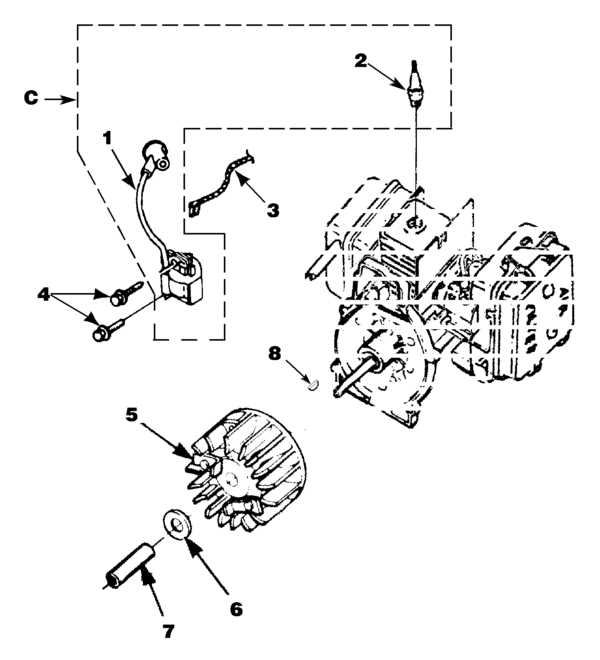

How to Read the Parts Diagram

Interpreting a parts layout effectively is key to understanding how a machine is constructed and how its components fit together. By analyzing the visual representation, you can pinpoint each individual piece and its specific function within the system. This knowledge is vital for troubleshooting and repairs, helping you identify what needs attention and how to make improvements.

Typically, the diagram is organized with numbered labels or clear sections for each component. You’ll see different parts, such as the engine, control mechanisms, and casing, with lines connecting them to show how they work in unison.

| Component | Function |

|---|---|

| Motor | Drives the entire mechanism, providing the power needed for operation. |

| Airflow System | Directs the output and ensures the proper distribution of air. |

| Control Panel | Allows the user to manage settings such as speed and power. |

| Housing | Protects the internal components from dust, dirt, and damage. |

Once you’re familiar with the layout, you’ll be able to use the diagram to locate specific components quickly and understand their role in the machine’s operation. This will make repairs and maintenance tasks much more manageable.

Identifying Common Equipment Issues

When using outdoor machinery, encountering issues is a common experience. Knowing how to recognize and diagnose these problems early can save time and money in the long run. By understanding typical malfunctions, you can take steps to fix them before they become more severe.

Here are some common issues that may arise with your tool:

- Reduced Power Output: This can be caused by issues with the motor or airflow system, preventing the machine from operating at full capacity.

- Overheating: Overheating can occur if the engine is clogged or if it’s running continuously without sufficient breaks. It may also indicate a cooling system problem.

- Difficulty Starting: If the tool doesn’t start, the spark plug or fuel system could be faulty, or the battery might need to be replaced.

- Excessive Vibration: This could point to loose parts or imbalanced components that are not properly aligned.

- Excessive Noise: Unusual sounds often indicate that internal components have worn out or that parts are improperly assembled.

By regularly checking for these common issues, you can keep your equipment in good working order. Early identification allows for simple fixes, which prolongs the life of your tool and improves its performance.