When it comes to maintaining your floor cleaning device, understanding how it works and knowing the various components involved is essential. Each machine is made up of key elements that contribute to its overall functionality, and recognizing these pieces can help in proper care and troubleshooting. Whether you’re fixing an issue or performing routine maintenance, having a clear understanding of the device’s internal setup makes a significant difference.

Knowing the different sections of the equipment ensures you can identify when something needs attention or replacement. This knowledge not only helps in extending the lifespan of the device but also enhances its cleaning efficiency. By examining each functional area, you gain a better grasp of how to keep everything running smoothly, from the water reservoir to the heating mechanism.

Proper maintenance involves regular inspection and sometimes disassembly, but with the right information, this becomes a manageable task. With the correct approach, small repairs or part replacements can be done easily, allowing you to keep your device in top condition without needing to rely on professional service. Let’s dive deeper into the structure of your equipment and explore the key components that play a vital role in its performance.

Understanding the Floor Cleaner Components

Every cleaning device is made up of several key elements that work together to ensure its optimal performance. Understanding how each section functions is crucial for troubleshooting, repairs, and maintaining the machine’s efficiency. These components range from the heating system to the water tank, all of which contribute to the overall cleaning process.

Essential Components of the Cleaning Equipment

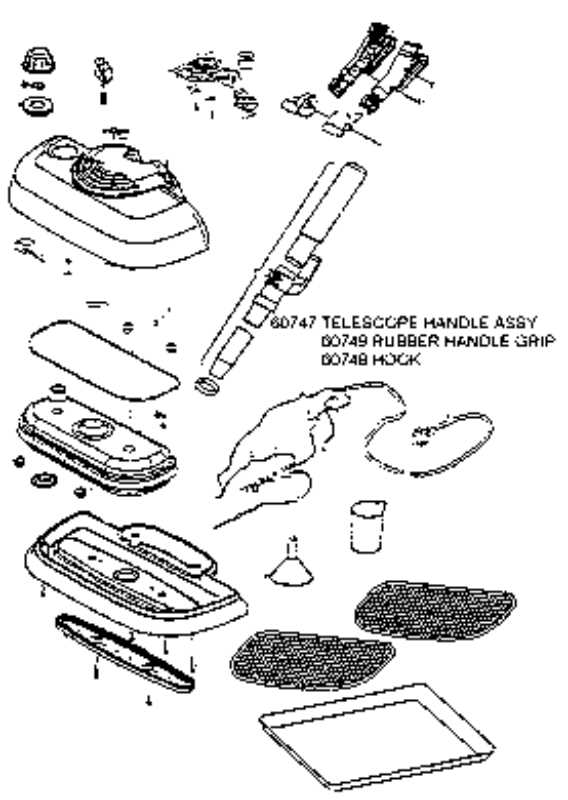

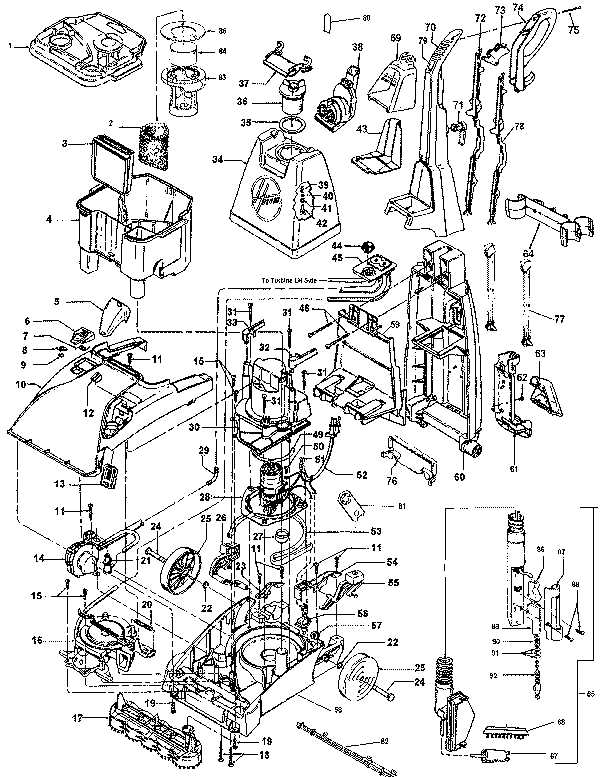

The device typically consists of a few central components: the reservoir, heating unit, cleaning head, and nozzle. Each piece plays a specific role in ensuring the machine can operate effectively. The water reservoir holds the liquid that is turned into steam, while the heating unit warms the water to the necessary temperature. The cleaning head is responsible for distributing the steam across the floor, and the nozzle controls the steam flow, directing it to the cleaning surface. Understanding how these parts interact can help in identifying potential issues and performing necessary repairs.

Maintenance and Care Tips

Regular maintenance is key to keeping your floor cleaner in working order. Ensuring that the reservoir is properly cleaned, the heating system is free from limescale, and the cleaning head is functioning without clogs is essential. By inspecting these components periodically, you can prolong the lifespan of the device and maintain its efficiency. Additionally, replacing worn-out or damaged parts promptly will prevent further damage and keep the machine running smoothly.

How to Identify Floor Cleaner Components

Recognizing the different sections of your cleaning device is crucial for effective troubleshooting and maintenance. Each part plays a unique role in the machine’s overall operation, and understanding their function can help you determine what needs repair or replacement. By familiarizing yourself with these components, you’ll be able to act quickly when something goes wrong and extend the life of your equipment.

Key Sections to Look For

The main parts of the device are typically easy to identify once you understand their general layout. The water container holds the liquid that gets transformed into steam, and the heating element is responsible for bringing it to the correct temperature. The head or cleaning pad distributes the steam, while the nozzle directs the flow for efficient cleaning. Knowing the function of each section will help you quickly locate any issues.

Common Signs of Malfunction

Once you know the components, it’s easier to spot signs of malfunction. A clogged or broken nozzle, for instance, could result in insufficient steam, while a damaged heating element will prevent the device from reaching the necessary temperature. Pay attention to any irregular sounds, leaks, or a decrease in performance, as these could indicate that one of the sections needs attention.

Common Floor Cleaner Components for Replacement

Over time, some elements of your cleaning device may wear out or become damaged, requiring replacement to maintain optimal performance. Recognizing the parts that are most prone to wear and tear can help you save time and money when servicing your machine. Below are some of the most common components that may need replacing throughout the lifespan of your equipment.

Frequently Replaced Components

- Water Reservoir: The container that holds liquid may crack or become clogged, requiring replacement to ensure proper steam production.

- Heating Element: If the machine fails to heat up, it could be due to a malfunctioning heating unit, which will need replacement for the device to function effectively.

- Cleaning Head: Over time, the head may become worn or damaged, leading to poor steam distribution. Replacing it ensures consistent cleaning results.

- Nozzle: A clogged or broken nozzle can obstruct the steam flow, requiring a quick replacement to restore full functionality.

Identifying When to Replace

Watch for signs that indicate a component needs to be replaced. If you notice a drop in cleaning efficiency, strange noises, or difficulty with steam flow, it might be time to check these common components. Prompt replacement will prevent further damage and ensure your floor cleaner operates as intended.