Efficient lawn care requires an understanding of the essential components that make up various maintenance tools. When it comes to keeping your garden equipment running smoothly, knowing the structure and function of each element is crucial. This knowledge enables easy troubleshooting and repairs, ensuring optimal performance throughout the year.

In this section, we will explore the key components of a garden maintenance device, identifying their roles and how they contribute to the tool’s overall functionality. Whether you’re looking to replace a part or simply want to gain a deeper understanding, this guide will provide valuable insights into the device’s internal mechanisms.

Understanding Lawn Maintenance Tool Components

When using a garden tool for regular upkeep, it is essential to understand the role of each internal component. This knowledge helps maintain the tool’s efficiency and ensures that it operates smoothly. Familiarizing yourself with the structure allows you to spot any issues early and address them before they cause more significant problems.

Each part of the device is designed to fulfill a specific function, from the motor to the cutting mechanism. The correct interaction between all components is what allows the tool to perform its tasks effectively. Recognizing these elements and their connections will make it easier to perform repairs or replacements when necessary.

In the following sections, we’ll break down the various components, discussing their roles and how they work together. Whether you are troubleshooting an issue or performing routine maintenance, knowing the different parts will improve your overall experience with the equipment.

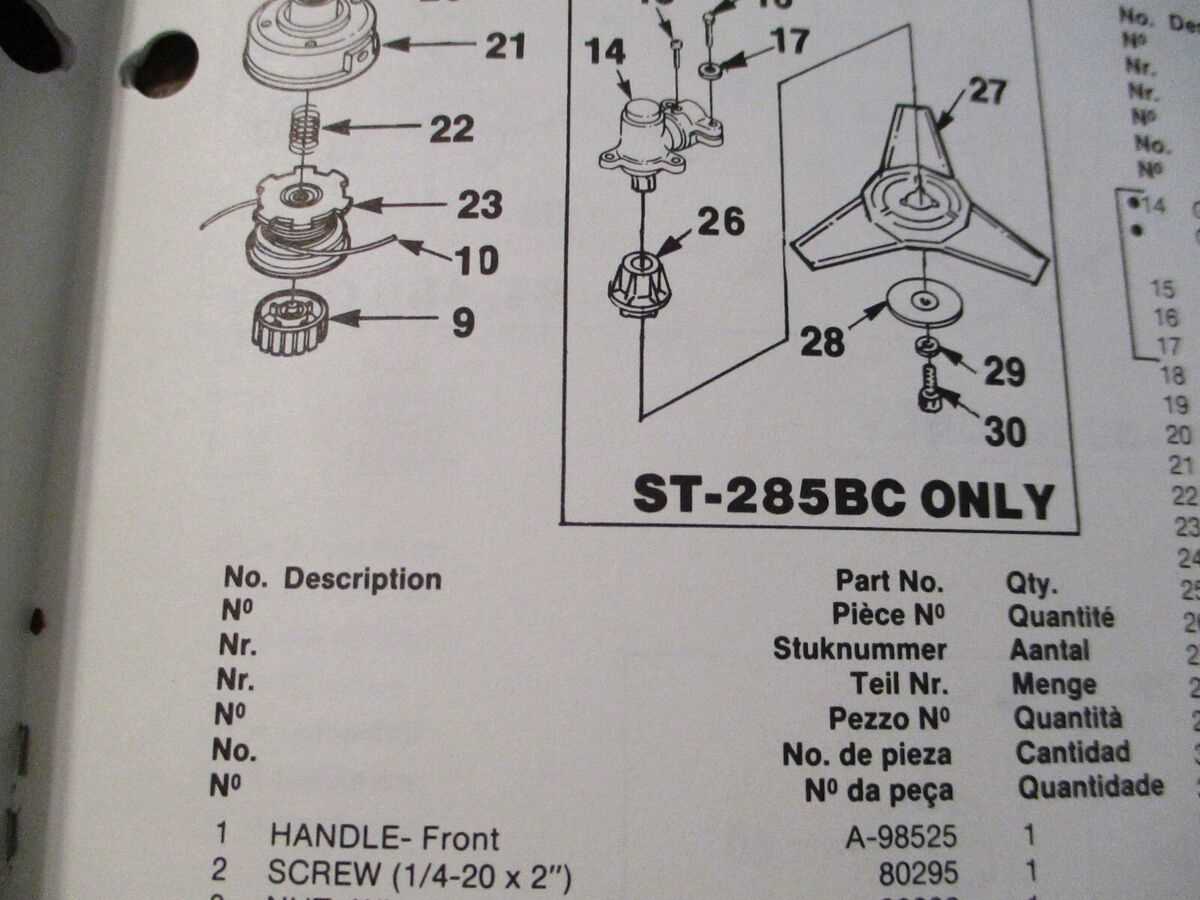

Identifying Key Parts for Efficient Repairs

To ensure your garden tool operates at peak performance, it’s crucial to recognize the essential components that require attention during maintenance. Identifying these parts allows for quicker diagnosis of any malfunctions and helps in choosing the right replacement or repair strategy. By understanding which elements are most likely to wear out, you can perform efficient repairs and prevent unnecessary breakdowns.

Key components such as the motor, the mechanism responsible for driving the cutting action, and the housing that contains them, play a vital role in the overall performance of the equipment. Knowing how these parts interact and wear over time ensures that you can address potential issues before they affect functionality.

Whether replacing a worn-out element or troubleshooting a malfunction, focusing on these crucial components will save time and money. Being able to pinpoint the exact issue makes the repair process much more straightforward and lessens the risk of further damage to the tool.

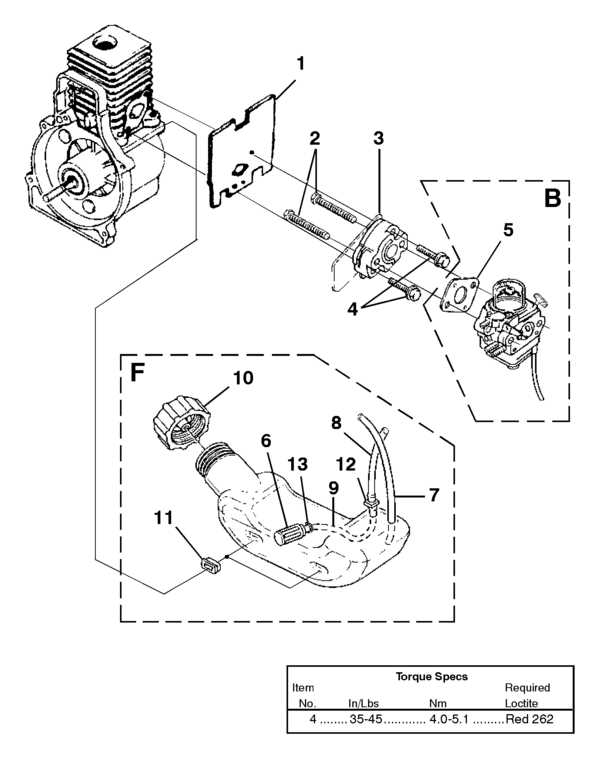

Step-by-Step Guide to Tool Assembly

Assembling a garden tool requires careful attention to each component to ensure proper functionality. Following a clear, step-by-step process helps you avoid errors and ensures that each part is securely connected. A well-assembled device operates more efficiently and can handle tasks without unnecessary strain or malfunctions.

Start by placing the main housing and motor in position. Make sure each part fits securely before moving on to the next. Attach any additional elements such as the cutting mechanism, ensuring that they align correctly with the motor’s drive system. Each piece should be firmly secured to prevent shifting during use.

Once the primary components are connected, proceed to check all fasteners and connectors. Tighten any loose screws or bolts to ensure stability. Finally, perform a function test to ensure that everything operates smoothly. A simple check will save time and frustration in the long run, confirming that the assembly is successful and the tool is ready for use.