Understanding the various components of your cleaning appliance is essential for proper care and effective use. By familiarizing yourself with how each part functions, you can ensure that your device performs at its best and lasts longer. Regular maintenance and timely repairs are crucial to avoid costly replacements and keep your machine running smoothly.

In this guide, we will break down the key elements of the machine, offering a detailed look at its structure. You’ll learn how to identify components, recognize signs of wear, and determine when it’s time for a replacement. With a comprehensive understanding of the individual parts, you can troubleshoot issues and maintain peak performance.

Effective maintenance is not only about keeping the appliance clean but also ensuring that every piece is functioning as it should. Being proactive about repairs can help prevent more significant damage in the future. Knowing the names and functions of essential components is the first step toward achieving optimal results from your machine.

Understanding Cleaning Appliance Components

Each cleaning machine is made up of several integral components that work together to ensure smooth operation. By becoming familiar with these parts, users can easily identify what each part does and how it contributes to the overall functionality of the device. Recognizing the role of every element allows for better maintenance and more efficient troubleshooting when issues arise.

These machines typically consist of a combination of brushes, water tanks, suction mechanisms, and electrical elements. Each component serves a unique function, whether it’s scrubbing surfaces, holding cleaning solutions, or facilitating the movement of the machine. Proper knowledge of each part will help you understand how the appliance operates and how to address any malfunctions effectively.

Understanding the inner workings of your device also means being aware of the signs that certain components may need attention or replacement. Regular inspection can prevent unexpected breakdowns and help keep the appliance in optimal condition, ensuring long-term efficiency and performance.

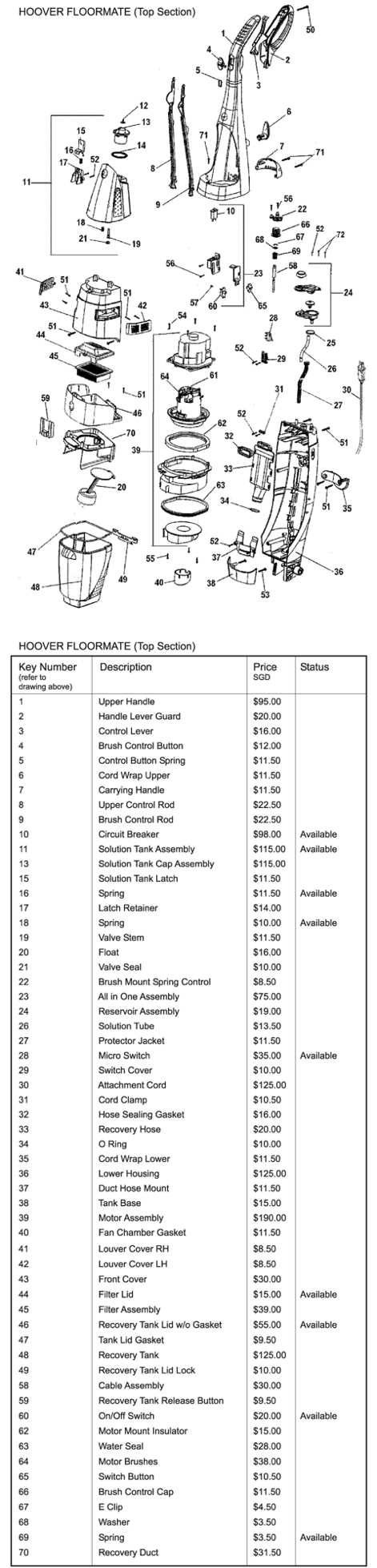

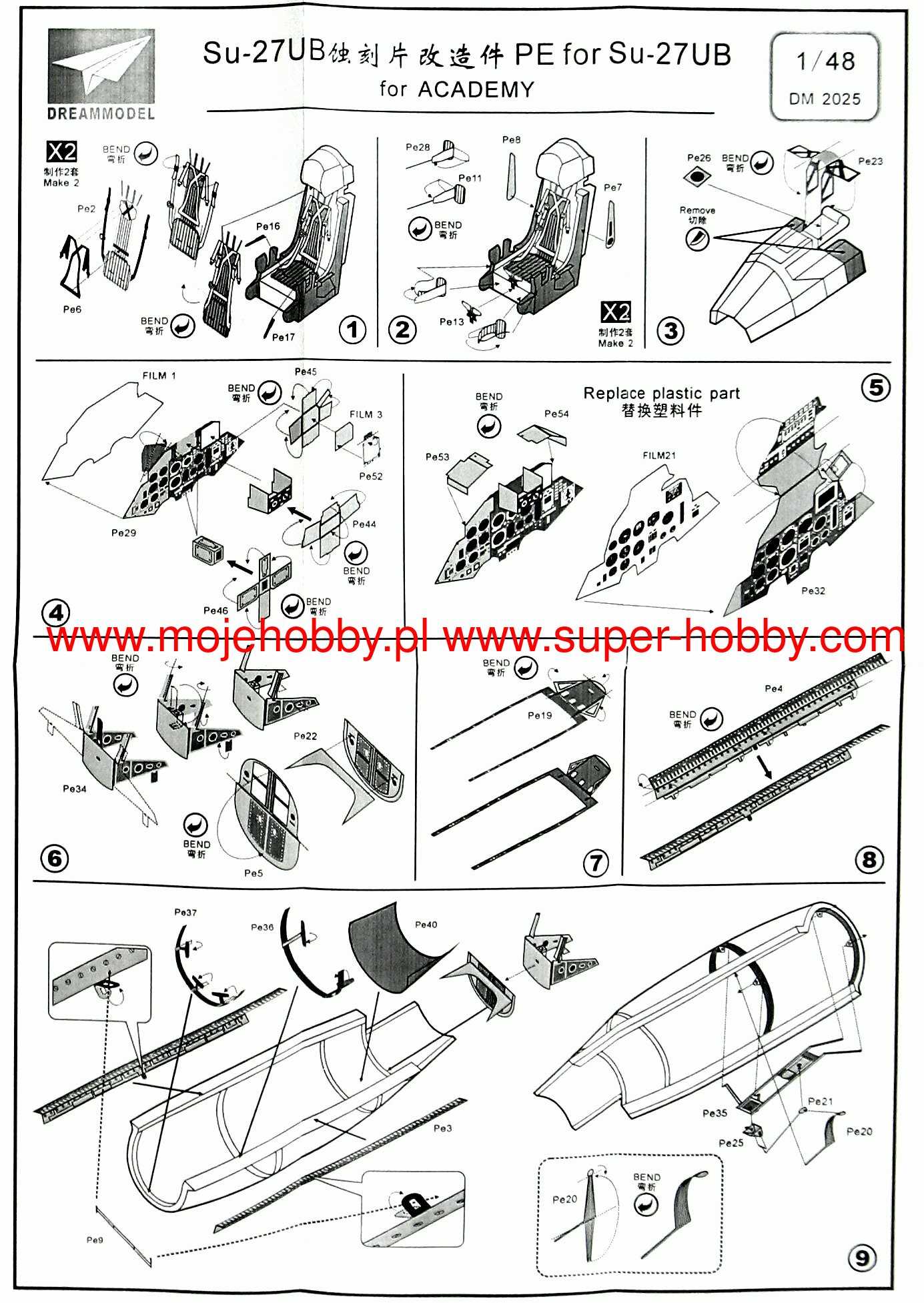

How to Read the Cleaning Appliance Layout

Reading the layout of a cleaning machine’s components can provide valuable insights for maintenance and repairs. The visual representation illustrates how the various parts are connected, making it easier to understand the overall structure and functionality. With this knowledge, users can pinpoint specific elements that may need attention or replacement.

Each element in the layout is typically labeled with both its name and the part number, making it simple to identify individual components. Some layouts also include arrows or lines that indicate how certain parts interact with each other, giving a clearer picture of their relationship within the system. This makes locating problems or understanding assembly much easier for both novices and experienced users.

When using such a layout, pay close attention to the key indicators like part numbers, labels, and visual connections between components. Understanding these details can make maintenance tasks more efficient, reduce the risk of errors, and speed up the repair process.

Common Cleaning Machine Replacement Components

Over time, certain elements of your cleaning appliance may wear out and require replacement to maintain performance. Identifying these components early on can prevent more significant damage and ensure your device continues to operate effectively. Some parts tend to degrade faster due to regular use, making them more common for replacement.

One of the most frequently replaced components is the brush or scrubber, as it comes into direct contact with surfaces and can become worn over time. Additionally, tanks that hold cleaning solutions may crack or develop leaks, necessitating a replacement to ensure proper function. Filters, which are essential for suction efficiency, can also become clogged or damaged and need to be changed periodically.

Other components that may need replacing include hoses, belts, and electrical connectors. These parts play a critical role in the machine’s mobility and power, and ensuring their good condition is crucial for maintaining overall functionality. Regularly inspecting these parts will help you keep the machine in optimal working condition and avoid inconvenient breakdowns.