When it comes to maintaining small engines, having a clear visual reference for their internal parts can be incredibly helpful. Identifying each component, from the carburetor to the ignition system, ensures proper maintenance and troubleshooting. With a well-organized chart or reference guide, even those with minimal mechanical experience can better understand engine function and repair needs.

Visual references are essential tools for anyone working on small engine systems, especially when trying to pinpoint issues or replace worn-out components. Whether you are a professional mechanic or a DIY enthusiast, knowing the layout of these systems can save you time and effort. A detailed map of engine components helps to navigate through complex repairs or upgrades with greater ease.

In this guide, we will explore the critical elements of a 37-horsepower small engine, highlighting the most common parts and their functions. By the end of this article, you’ll have a deeper understanding of how these engines work and what you need to know for successful repairs and maintenance.

Understanding the 37 HP Engine Components

Small engines, especially those with higher horsepower, consist of various critical components that work together to ensure optimal performance. From the fuel system to the exhaust, each part plays a vital role in the engine’s overall function. Understanding these key components is essential for both effective maintenance and troubleshooting.

The heart of the engine lies in its internal mechanisms, which include the crankshaft, pistons, and valves. These elements work in unison to create power by converting fuel into mechanical energy. Additionally, the ignition system, including the spark plug and coil, is crucial for initiating combustion. A failure in any of these parts can result in poor engine performance or even complete failure.

Another significant group of components is the fuel and air intake system. The carburetor, fuel injectors, and filters are responsible for delivering the right mixture of air and fuel to the engine. A properly functioning intake system ensures smooth operation, efficient fuel use, and reduces the risk of engine knock or overheating.

Finally, the cooling system, including the radiator and fan, helps maintain optimal operating temperatures, preventing damage from excessive heat. Regular inspection and proper maintenance of these parts can extend the lifespan of the engine and ensure it runs at peak efficiency.

How to Read the Engine Component Layout

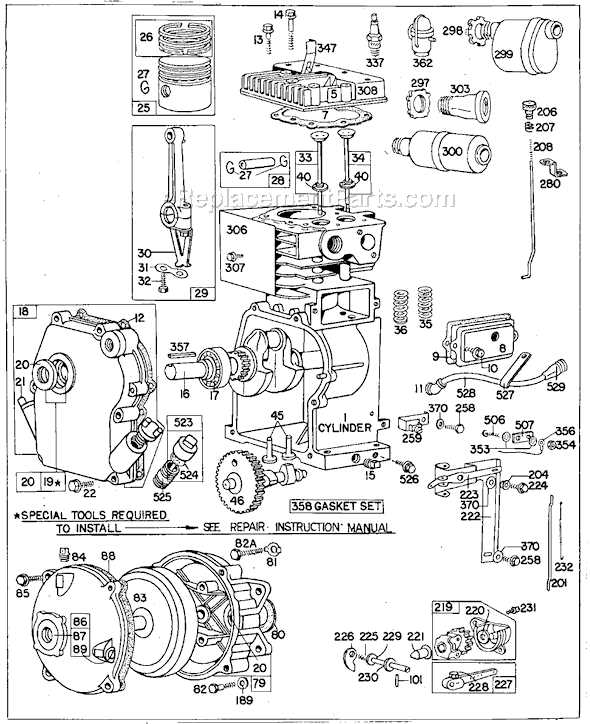

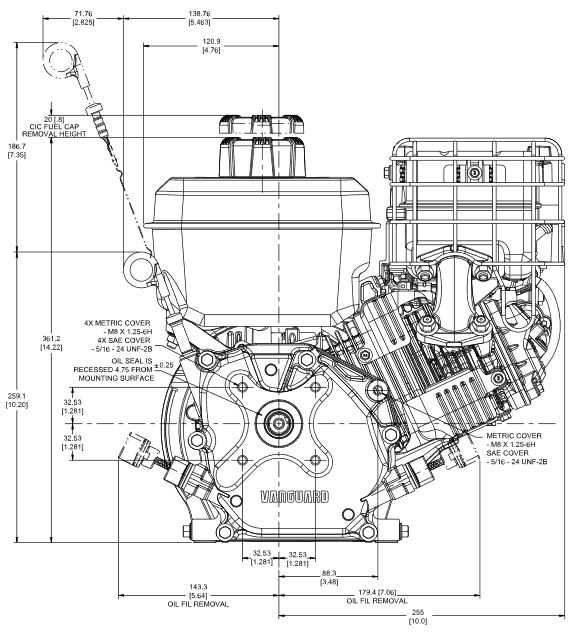

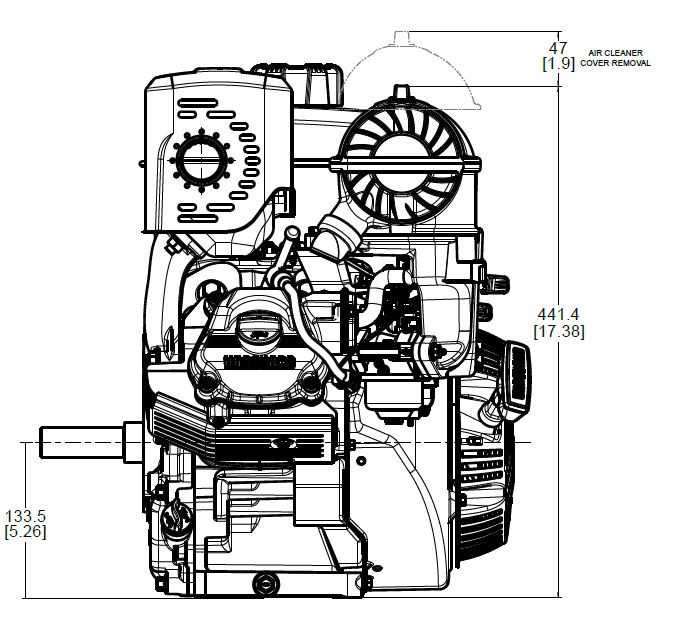

Understanding a component layout or schematic is crucial for anyone working with small engines. These illustrations provide a visual representation of how different parts are arranged and interact within the system. By knowing how to read these guides, you can more easily identify each component and its function, making maintenance and repairs more efficient.

Typically, these layouts are broken down into sections, each representing a different part of the engine, such as the fuel system, electrical system, or cooling system. Each component is labeled, often with a reference number or code, which can be cross-referenced with a parts list for more detailed information. Pay attention to how the parts connect or align with each other, as this can give clues about how they work together.

One of the key things to look for when studying these diagrams is the orientation of the components. Often, the layout will be presented from a specific viewpoint, such as the front or side of the engine, and this perspective can impact how parts are identified and understood. Understanding this will help you recognize where each component fits and how it functions within the larger system.

Additionally, note the differences between various types of engines and layouts. Some systems may have more complex components, such as multiple fuel injectors or advanced electrical systems, while others might have simpler setups. Being familiar with the typical structure of a 37-horsepower engine will help you interpret these guides more effectively.

Common Issues with 37 HP Engine Components

Even the most reliable engines can experience issues over time, and small engines are no exception. Common problems often arise due to wear and tear, poor maintenance, or improper handling. Understanding these issues can help prevent costly repairs and extend the life of the engine. Let’s explore some of the most frequent problems that can occur with a 37-horsepower engine.

Fuel Delivery Problems

One of the most common issues with small engines is fuel delivery failure. Over time, fuel lines can become clogged with debris, or the carburetor may get gummed up from old fuel. If fuel isn’t reaching the engine properly, it may lead to hard starting or stalling. Regularly cleaning the fuel system and using fresh, clean fuel can help prevent these issues.

Ignition System Malfunctions

A faulty ignition system can cause starting issues and poor engine performance. Worn spark plugs, corroded ignition coils, or damaged wiring can disrupt the engine’s ability to fire properly. Regular inspection and timely replacement of these components are essential for reliable engine operation.