Every garden or industrial water management system relies on a set of interconnected elements that work together to ensure smooth operation. Recognizing the individual functions of each component is essential for effective maintenance and problem-solving. Whether you’re a professional or a DIY enthusiast, understanding these key elements will help you make informed decisions when it comes to repairs or upgrades.

Identifying the various sections of the system can sometimes be a challenge, especially when you’re unfamiliar with their design and purpose. However, with the right knowledge, you can easily spot which parts need attention and which are functioning as expected. This knowledge ensures that your system will remain in top condition for optimal performance.

Regular inspections and basic troubleshooting practices can prevent common issues from escalating. By familiarizing yourself with the structure and working of each section, you will be better equipped to tackle maintenance tasks, extending the life of the system and improving its efficiency over time.

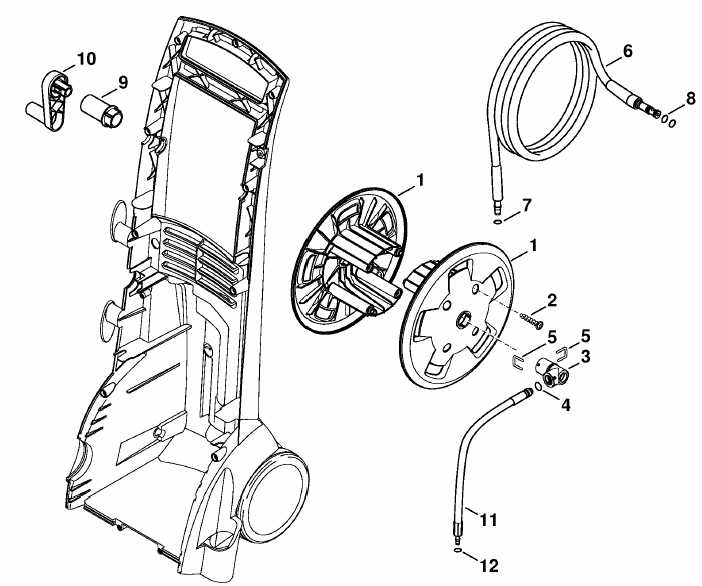

Hose Reel Components and Their Functions

The functionality of any water distribution system is determined by the cooperation of several interconnected components. These elements are carefully designed to handle tasks like storing, distributing, and retracting the material used in the system. Understanding the role of each component helps ensure smooth operation and efficient performance. Each section serves a specific purpose, from guiding the flow to facilitating easy storage.

Core Elements of the System

The central unit is designed to provide support and manage the materials within the system. It houses mechanisms for controlling tension, allowing for smooth deployment and retraction. Other key components include the rotating mechanism that aids in easy storage and the supporting frame that holds everything in place.

Control and Support Mechanisms

At the heart of this system lies the control mechanism, which enables users to adjust the flow or manage the retracting process. Additionally, the support structure ensures stability and proper alignment, preventing any unwanted movements or damage during use. Together, these components work seamlessly to provide an effective and user-friendly system for everyday use.

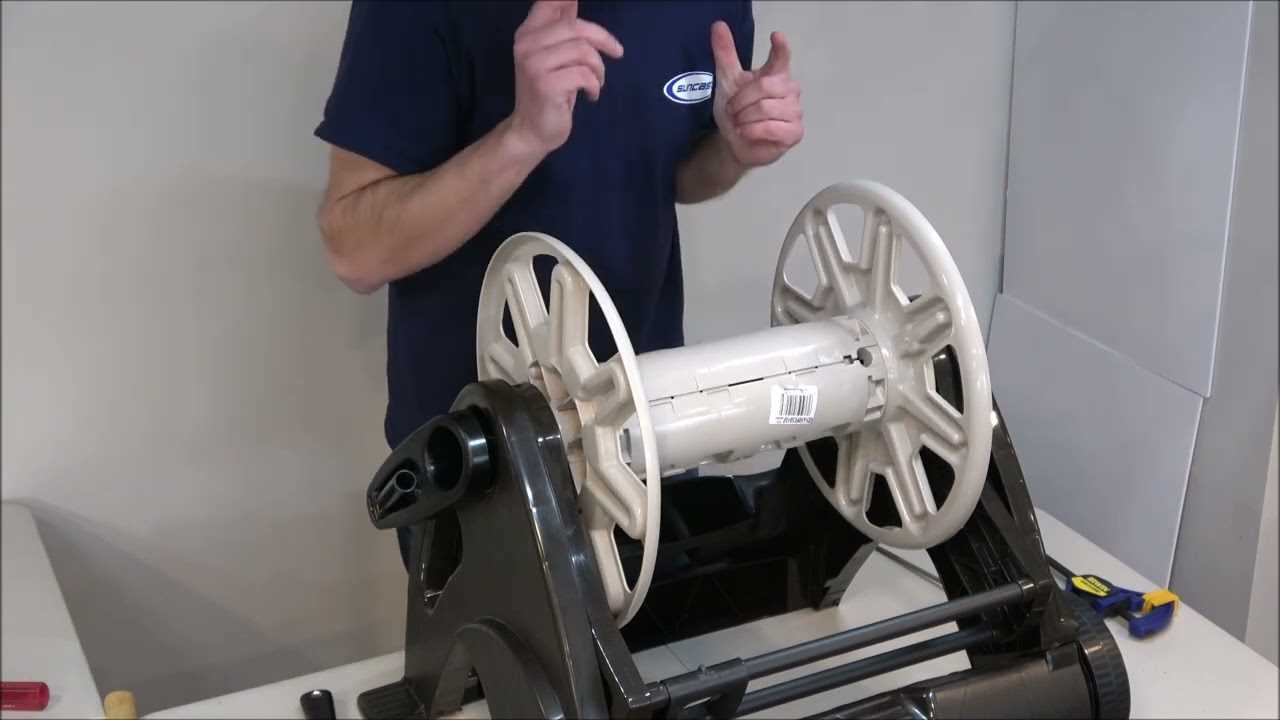

How to Identify Hose Reel Parts

Recognizing the various components within a water distribution system is crucial for effective maintenance and repair. Each element plays a distinct role in ensuring smooth operation. Whether you’re troubleshooting or performing routine inspections, being able to identify these sections will help you understand how the system works and where potential issues may arise.

Key Features to Look For

The first step in identifying components is to examine their shape, size, and function. Look for elements that are responsible for guiding, supporting, or retracting the material. These key features often help distinguish between the main structural supports and the moving elements that facilitate the system’s operation.

Understanding the Function of Each Section

Once you’ve located the components, the next step is to understand their specific function. Some sections are designed to hold the material in place, while others are responsible for controlling the tension and enabling movement. Understanding these functions will make it easier to detect wear or damage that may need attention during your inspections.

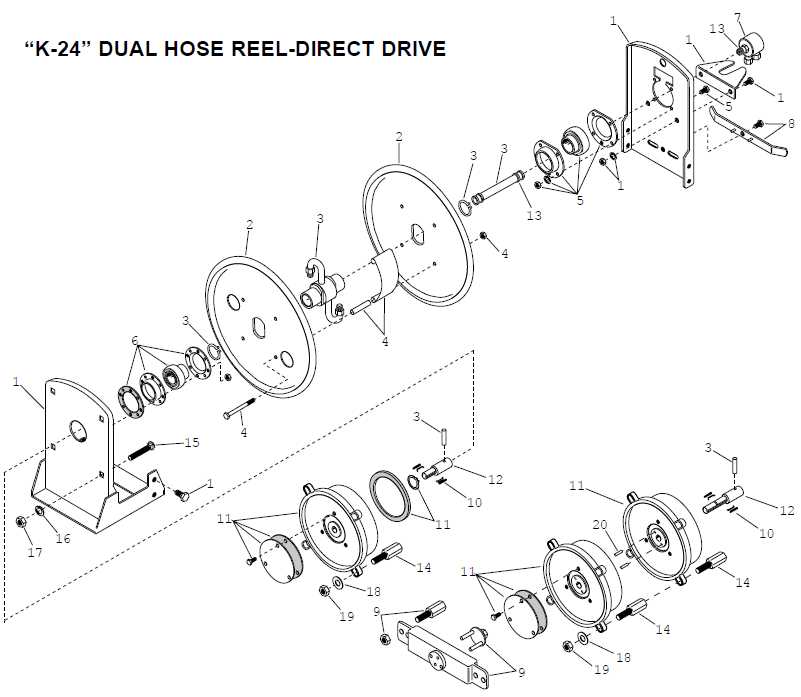

Maintaining Your Hose Reel Assembly

Proper upkeep of a water management system is essential for ensuring its longevity and optimal performance. Regular maintenance helps prevent breakdowns and prolongs the life of individual components. Understanding the critical areas to focus on during maintenance will help you keep the system running smoothly and avoid costly repairs.

Inspection and Cleaning

One of the first steps in maintaining your system is routine inspection. Check for any wear or damage on the structural supports, rotating mechanisms, and tension control units. Cleaning the system regularly ensures that no debris or dirt interfere with its operation. Pay special attention to areas where friction occurs, as these are prone to wear over time.

Lubrication and Adjustment

Lubricating moving parts is essential to minimize friction and wear. Apply a suitable lubricant to rotating mechanisms and tension control sections to maintain smooth operation. Regularly adjust the tension to prevent strain on the components and ensure proper storage and deployment when needed. This proactive approach will keep your system functioning effectively for years to come.