Maintaining high-performance cleaning equipment requires a solid understanding of its internal structure. Knowing the function of each component allows users to troubleshoot and replace faulty elements efficiently. This guide will help you identify key sections and explore how they work together to ensure optimal functionality.

By familiarizing yourself with the key elements of your machine, you can address common issues and perform necessary repairs without the need for professional assistance. The following sections will walk you through the essential parts and their roles, as well as offer tips for identifying and replacing damaged components.

Empower yourself with the knowledge to keep your equipment running smoothly for years. Whether it’s for routine maintenance or solving specific issues, understanding the layout of your machine is a crucial first step.

Understanding the Key Components of Your Cleaning Equipment

Every cleaning device consists of various critical elements that work in harmony to provide the performance you expect. These components, though individually distinct, all contribute to the overall functionality of the machine. Understanding how they interact can help you with troubleshooting, repairs, and ensuring long-term reliability.

Main Functional Elements

The primary sections of your equipment include the motor, pump, and the various hoses that regulate water flow. Each of these elements plays a crucial role in ensuring efficient operation. A clear understanding of these core components allows users to pinpoint specific issues when the machine isn’t performing as expected.

Internal Mechanisms and Flow Regulation

Inside the machine, internal mechanisms like valves, seals, and the control system help regulate the operation and flow of water. These elements are often where issues arise, such as leaks or blockages. Familiarity with the configuration of these components will help you diagnose and replace damaged parts with ease.

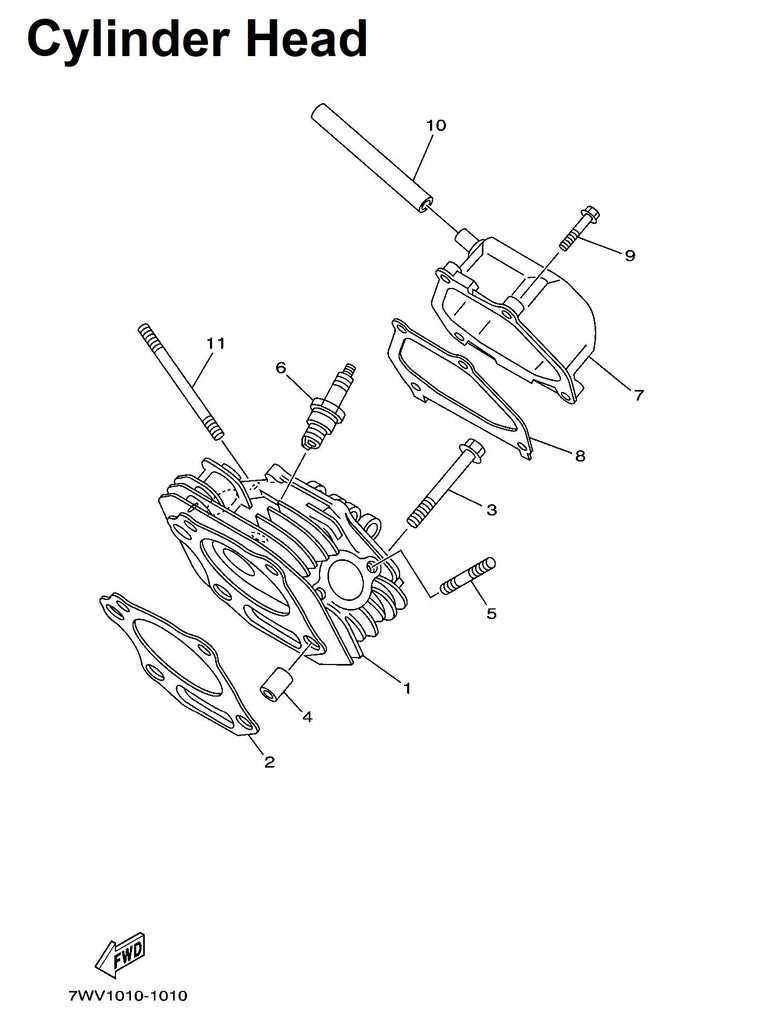

How to Identify Key Components in the Diagram

Recognizing the main elements of your cleaning machine is essential for understanding its operation and addressing potential issues. A well-detailed diagram can serve as a map, guiding you through each segment of the machine. Identifying these components helps in pinpointing where specific problems may arise and where replacements are necessary.

Locating the Central Components

The first step is to locate the primary components, such as the motor, water intake, and pressure regulator. These sections are typically highlighted in the diagram and are crucial for the overall function of the device. Once you’ve identified these key elements, you can trace their connections to see how they work together.

Understanding Flow and Connections

Next, focus on understanding the flow of water and the connection between various components. The diagram will typically include lines or arrows to show how water moves through the system, helping you see where blockages or leaks may occur. Familiarizing yourself with these flow paths can make diagnosing issues easier.

Common Issues and Replacement Parts for Your Cleaning Equipment

Like any mechanical device, your cleaning equipment may experience wear and tear over time. Identifying common issues early can save both time and money. Understanding the components that are most likely to fail and knowing how to replace them ensures that your machine continues to operate effectively.

Common problems include worn-out seals, malfunctioning motors, and damaged hoses. These issues can lead to reduced efficiency or complete failure if not addressed promptly. Having replacement components on hand, such as new seals, filters, or motors, will allow you to perform quick repairs and avoid downtime.

It’s also important to keep an eye on internal elements like valves and the water flow control system. Regular inspection of these parts helps prevent issues before they escalate and ensures that your machine continues to run smoothly.