When working with complex machinery, understanding the internal components and their connections is essential for smooth operation and troubleshooting. A clear breakdown of the system’s individual elements allows users to identify potential issues and perform necessary maintenance efficiently.

Having a visual representation of how different sections interact helps with both repair and optimization. Whether you’re a professional technician or a DIY enthusiast, knowing where each piece fits within the larger structure is crucial for effective use and longevity of the machine.

By examining detailed illustrations, you can easily locate specific components, assess their condition, and ensure they are properly maintained or replaced as needed. Proper knowledge of the system enhances both functionality and safety during operation.

Understanding Key Components of Husky Compressors

Every mechanical system consists of various interconnected elements that work together to ensure smooth operation. Identifying these key components and understanding their functions is crucial for effective maintenance and troubleshooting. Each part plays a vital role, and recognizing how they contribute to the overall performance can prevent unexpected failures.

At the core of most systems are power-driven units that supply the necessary force to generate movement or pressure. These engines are complemented by control systems that regulate their output, providing efficiency and consistency during use. Additional components, such as tanks, valves, and filters, ensure that the system runs smoothly and safely, optimizing performance.

Recognizing the structure and layout of these elements allows for faster diagnostics and a more efficient repair process. By familiarizing yourself with the key components, you can maintain a high level of performance and extend the lifespan of your equipment.

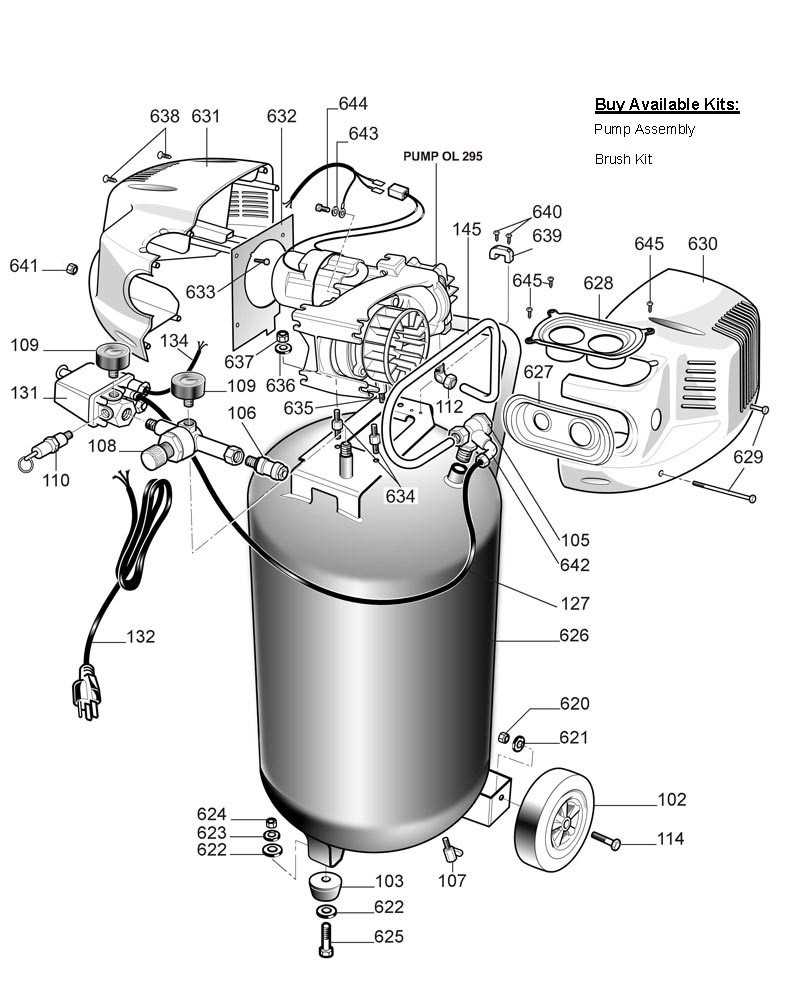

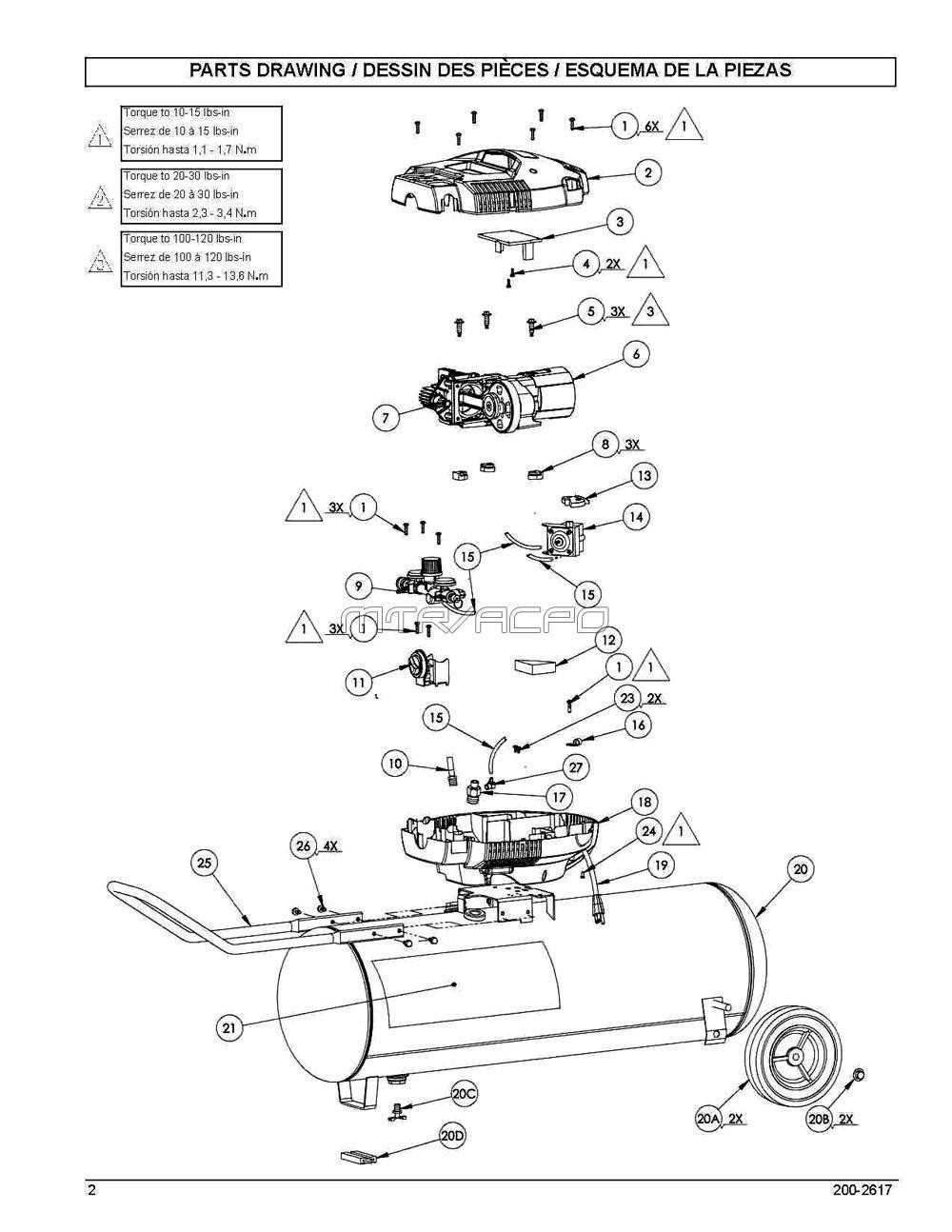

How to Read the Parts Diagram Effectively

Interpreting a schematic representation of a mechanical system requires careful attention to detail and an understanding of how components interact. The ability to read and understand these visual guides is essential for diagnosing issues, performing repairs, or assembling equipment. Familiarity with common symbols, layout patterns, and the relationship between elements can significantly speed up troubleshooting and maintenance tasks.

Familiarize Yourself with Symbols

Each diagram typically uses standardized symbols to represent various components. Recognizing these symbols helps you quickly identify individual parts, such as motors, valves, or piping. Once you become familiar with the symbols, the flow of the system will become much clearer, allowing you to focus on specific areas that may require attention.

Understand Component Connections

It’s equally important to comprehend how the components are interconnected. Pay attention to the lines or arrows showing flow direction or electrical connections. These indicators provide crucial insight into how energy or pressure moves through the system, which can help pinpoint malfunctions or inefficient parts.

Common Issues and Maintenance Tips

Maintaining mechanical systems is essential to ensure longevity and consistent performance. Over time, certain issues may arise, affecting the overall functionality of the machine. Regular maintenance and understanding the most common problems can help prevent costly repairs and extend the lifespan of the equipment.

Identifying Leaks and Pressure Loss

One of the most frequent issues is a loss of pressure due to leaks in hoses or seals. These leaks can significantly reduce efficiency and increase energy consumption. Periodically inspect all connections and joints for signs of wear or damage. Tightening connections or replacing worn seals can often resolve this problem.

Maintaining Proper Lubrication

Another common concern is the lack of proper lubrication, which can cause excessive wear on moving parts. Without adequate lubrication, friction increases, leading to overheating and potential component failure. Ensure that lubrication levels are regularly checked, and use the manufacturer’s recommended oil or grease for optimal performance.