Effective irrigation relies on the proper function of various essential elements working in harmony. These components allow for a precise distribution of water, ensuring the healthy growth of plants. A well-organized system provides uniform coverage, conserving both water and energy. Below, we explore the different components of a typical irrigation mechanism.

Key Elements of the Irrigation Mechanism

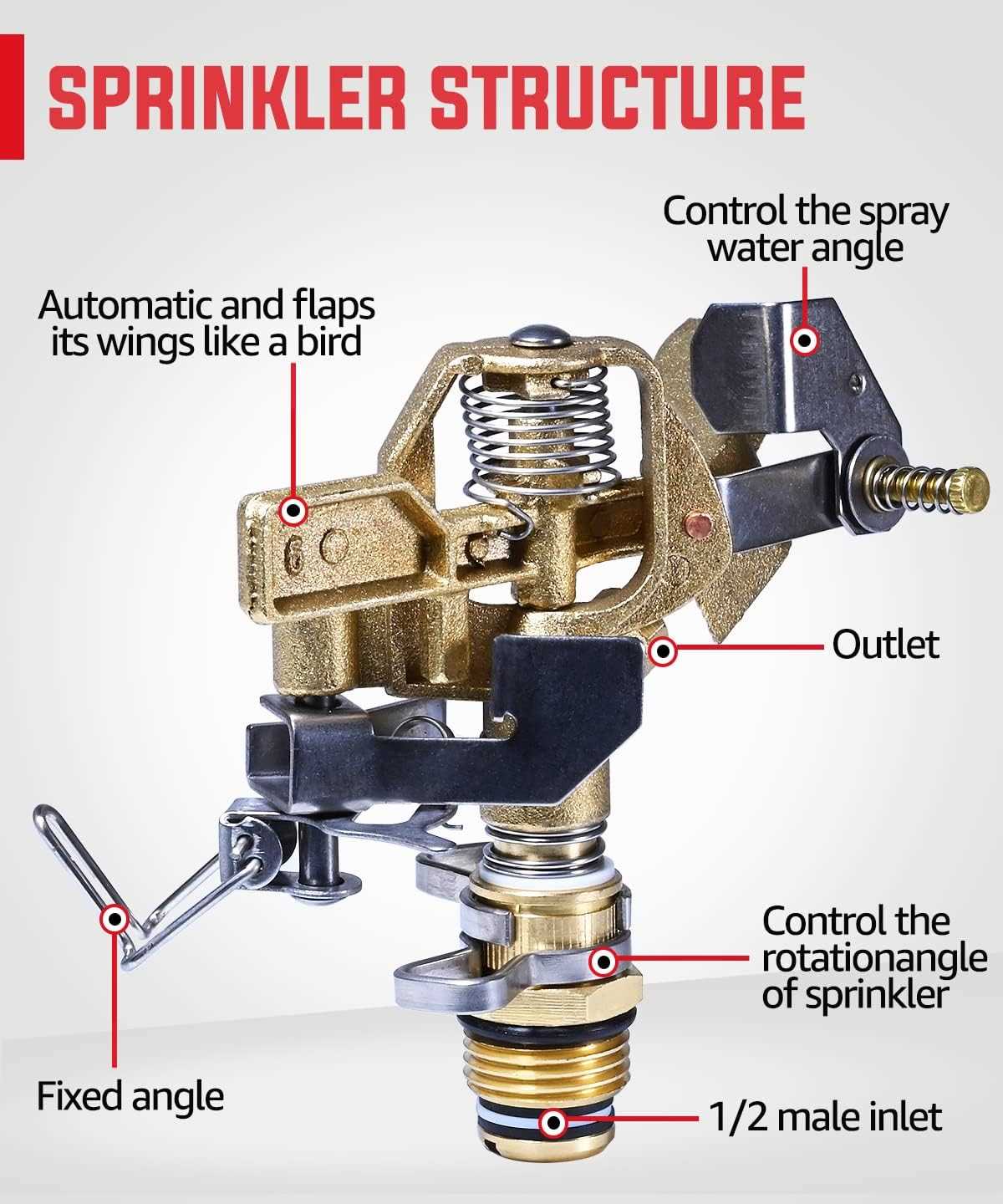

The central part of this system consists of various moving and stationary elements. Each element plays a specific role in delivering water to the intended area. Understanding these parts is crucial for troubleshooting and maintaining the efficiency of the setup.

Rotating Mechanisms

Rotating parts are responsible for dispersing water over a wide area. These often operate on a pivot, allowing the water to reach the soil at various angles. The spinning motion ensures even coverage, reducing the need for manual adjustments.

Water Flow Control

Flow regulation components manage the volume and pressure of water being released. These are essential for maintaining the optimal flow rate and ensuring that the water reaches each plant effectively without wasting resources.

Internal Components and Their Functions

Inside the system, numerous components work together to achieve seamless operation. These elements range from those that ensure movement and rotation to those that secure the system’s structural integrity. Regular inspection of these internal parts helps in preventing malfunctions and ensuring long-term durability.

Movement Mechanism

At the heart of this system, the movement mechanism ensures that the entire setup moves in a predetermined pattern. This movement helps to avoid over-watering or missing sections of the area needing attention.

Supporting Framework

Structural components keep the system in place and support its various parts. These sturdy elements prevent wear and tear, ensuring that the mechanism functions efficiently for extended periods.

Common Issues and Solutions

Like any mechanical setup, issues can arise with time and usage. However, by understanding common faults, users can quickly diagnose problems and perform necessary repairs to restore functionality.

- Clogged nozzles: Can be cleaned or replaced to restore full functionality.

- Worn-out seals: These can be replaced to prevent leaks and maintain pressure.

- Imbalanced flow: Often caused by a malfunctioning regulator, this can be adjusted for more consistent distribution.

With proper maintenance, users can maximize the life and efficiency of their irrigation systems, ensuring plants receive the water they need without excess waste.

Understanding Irrigation System Design and Operation

Effective irrigation systems are designed to distribute water evenly across large areas. These systems rely on a variety of components that work together to ensure optimal performance and water conservation. Understanding how each part functions and contributes to the system’s overall efficiency is crucial for both installation and maintenance.

The main components of a functioning irrigation system include rotating mechanisms, water regulators, and distribution channels. These elements control the movement and volume of water, ensuring that every section of the garden or field receives the necessary amount of moisture without waste. A properly configured system will rotate or move across the designated area to provide consistent coverage.

Efficient operation depends on the synchronization between these components. The movement system allows for a broad coverage area, while regulators ensure that the water pressure is appropriate for the size of the area. When all elements work in harmony, the irrigation system operates at peak efficiency, ensuring that water is distributed properly and conserves both resources and energy.

Internal mechanisms are responsible for controlling the movement and flow of water. These often involve gears, springs, and seals that help to maintain smooth operation. Regular checks of these internal components are essential for preventing wear and tear, which can affect the system’s functionality.

Common issues that arise with these systems include blockages, leaks, and uneven water distribution. Blockages may occur in the flow channels, affecting the pressure and reach of the system. Leaks can cause water loss and reduce efficiency, while uneven distribution can lead to over-watering or dry spots. Routine maintenance and prompt repairs ensure long-lasting, reliable performance.