Every kitchen appliance consists of multiple components that work together to ensure smooth operation. Having a clear understanding of how these parts fit together can significantly ease the process of maintenance and troubleshooting. Whether you’re looking to replace a worn-out piece or simply trying to identify specific functions, knowing the layout and function of each section is crucial.

In this guide, we will explore the inner workings of your kitchen mixer. We’ll help you identify essential parts, explain how they function, and provide a visual reference for when you need to make repairs. With this knowledge, you’ll be equipped to address any mechanical issues and extend the lifespan of your appliance.

Maintenance and repair become easier when you understand the role of each component, from the motor to the attachments. This article will also assist you in navigating the complexities of appliance upkeep, empowering you to handle minor fixes independently. By familiarizing yourself with the internal structure of your mixer, you can keep it running efficiently for years to come.

Understanding Your Kitchen Mixer Components

Every kitchen mixer is built from a series of interconnected elements that work in unison to perform tasks efficiently. Each component has a specific role, whether it’s providing power, transferring motion, or aiding in mixing and kneading. Familiarizing yourself with these key elements is essential for effective maintenance and troubleshooting.

Within your appliance, you’ll find parts that manage everything from the motor’s power to the attachment system. Some components handle the mixing speed, while others ensure that ingredients are incorporated evenly. Understanding their layout and functionality can help identify issues before they become major problems.

Being aware of the various sections and their interdependencies allows for smoother repairs and part replacements. With the right knowledge, even a novice user can successfully maintain and fix minor issues without relying on professional help, saving both time and money in the long run.

How to Read Appliance Component Diagrams

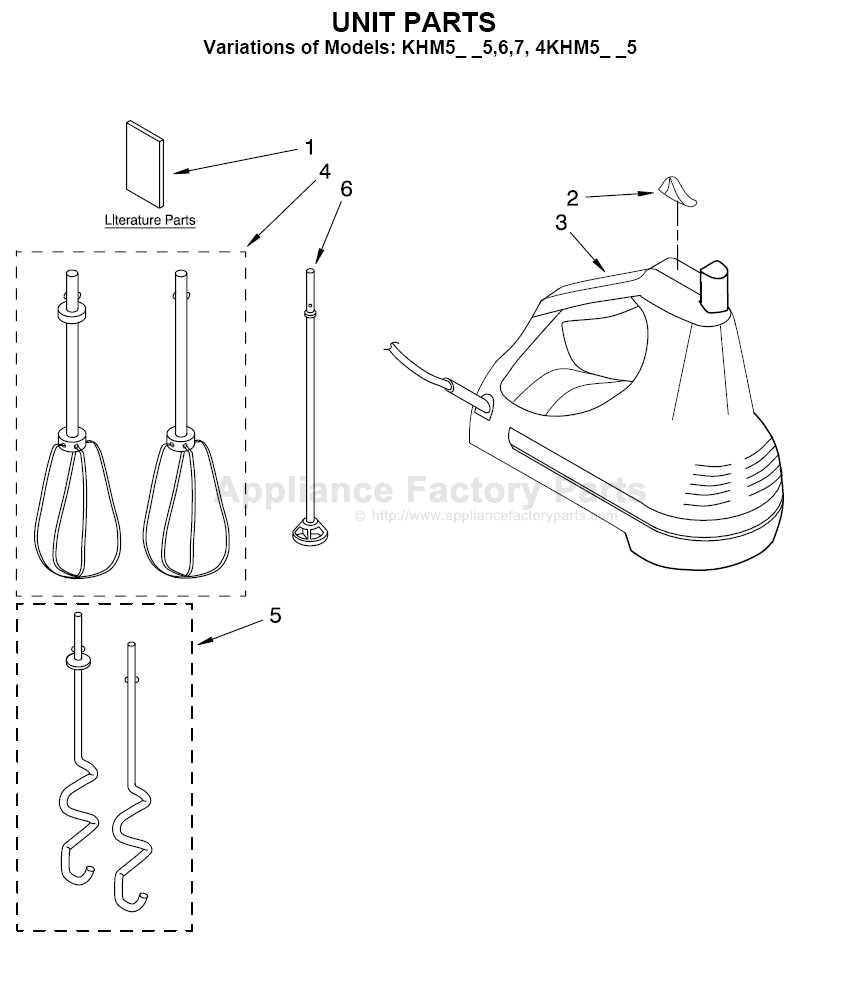

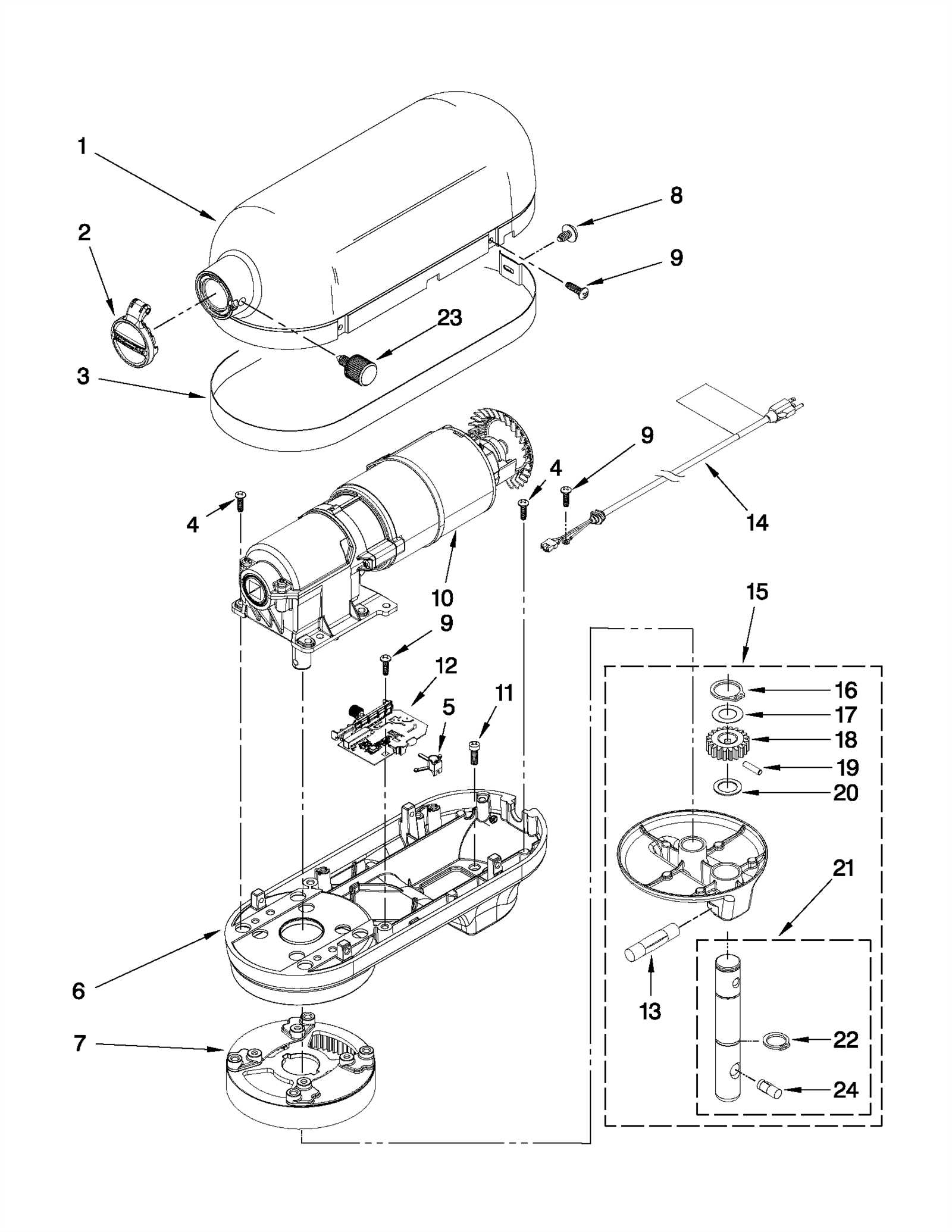

Understanding the visual representation of your kitchen mixer’s internal elements is key to making effective repairs and identifying issues. These detailed illustrations show the layout of all essential components and how they interact. To make the most of this information, it’s important to know how to interpret the symbols, connections, and labels provided in these diagrams.

Identifying Components and Labels

Each part in the diagram is labeled with a specific identifier, typically a number or code. These labels correspond to a list or key that describes the part in detail. It’s essential to familiarize yourself with these identifiers so you can quickly locate the components you need to examine or replace. Pay attention to any special symbols that indicate orientation or movement directions, as these are crucial for assembly and disassembly.

Understanding Connections and Relationships

The lines and arrows in the diagram show how the components are connected. Arrows usually represent movement or flow, while lines indicate physical connections. Understanding these relationships is vital, as it helps in troubleshooting mechanical problems by showing which parts work together and which may be affecting others.

Common Appliance Component Issues

Like any mechanical device, kitchen mixers can experience problems over time due to wear and tear or improper maintenance. Understanding the most common issues with internal components can help you identify and address them quickly. These issues often stem from mechanical failure, misalignment, or simple dirt and debris buildup.

One frequent issue is a malfunctioning motor, which may result in the appliance failing to start or running at inconsistent speeds. This can often be linked to worn-out brushes or a faulty power connection. Another common problem is the attachment mechanism, which can become loose or fail to connect properly due to damaged pins or gaskets.

Additionally, the mixing gears and belts may wear out or lose alignment, leading to reduced efficiency or strange noises during operation. This type of issue is typically caused by overuse or improper loading of ingredients. Regular checks and maintenance of these key areas can prevent most of these common problems from escalating into more serious issues.