Understanding the internal structure of complex machinery is essential for efficient operation and troubleshooting. Proper knowledge of how different elements interact with each other ensures smoother functionality and easier maintenance. A clear visual representation can make it much easier to identify and replace damaged or worn-out components, saving time and resources in the long run.

Whether you are a professional technician or a DIY enthusiast, having access to detailed diagrams and clear instructions helps when performing repairs. This guide will equip you with the necessary information to approach maintenance with confidence, ensuring that you can tackle any issue that arises.

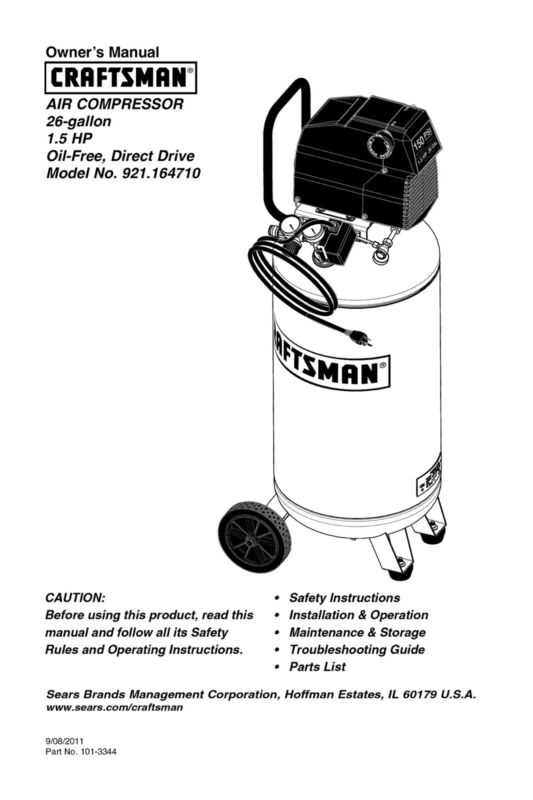

Understanding the Jobsmart Air Compressor Design

The design of mechanical systems plays a crucial role in their efficiency and longevity. A well-organized structure with interrelated components working in harmony ensures smooth operation. Understanding how each part functions and contributes to the overall system is key for both troubleshooting and maintenance tasks.

For optimal performance, it is essential to recognize the different segments that make up the equipment. From the power source to the auxiliary units, each piece serves a specific function to maintain continuous operation. Recognizing the interconnectedness of these components is vital when diagnosing issues or planning for replacement of any malfunctioning unit.

Effective maintenance relies on understanding the engineering behind these machines. By studying their layout and design, technicians can identify weaknesses and enhance durability. Additionally, this knowledge allows users to approach repairs with confidence, ensuring that all elements are properly handled and restored when necessary.

Key Components of the TA-25100VB Model

Every mechanical unit consists of several essential components that work together to ensure smooth performance. Understanding these core elements is fundamental to both operation and troubleshooting. Each segment of the system plays a unique role in maintaining functionality and preventing common issues.

Motor and Power Source

The motor is the heart of the system, converting electrical energy into mechanical power. A reliable power source ensures that the unit runs efficiently without interruptions. Regular maintenance of the motor, including lubrication and inspection of connections, helps prevent overheating or electrical faults, keeping the equipment running smoothly for long periods.

Air Delivery Mechanism

This component facilitates the movement and compression of the internal elements. Its role is crucial for ensuring that the output remains consistent and at the correct pressure. Over time, wear and tear may affect the flow, and understanding its construction allows for quick identification of any blockages or damage that could impact performance.

How to Use the Parts Diagram for Repairs

When performing maintenance on complex machinery, having a detailed visual representation of the system can significantly simplify the process. A well-organized diagram provides clear guidance on where each component is located and how it connects to others, allowing you to easily identify parts that need repair or replacement.

To make the most of the visual guide, start by identifying the part numbers or labels associated with each component. This will help you pinpoint the specific unit causing issues. Once you have located the problematic area, refer to the diagram for step-by-step instructions on how to disassemble, repair, or replace the damaged parts. This approach minimizes errors and ensures that the repair process is carried out efficiently.