When it comes to maintaining any equipment, understanding its structure is crucial for effective operation. Proper knowledge of the various elements that work together ensures smooth functioning and prevents common issues from escalating. In this section, we explore the essential components of a typical spraying device, breaking down its key features for easier troubleshooting and repair.

Each system is made up of several interconnected parts that perform specific tasks. By identifying these components and learning how to handle them, you can improve the performance of the machine and extend its lifespan. We provide a detailed breakdown to help you visualize how everything fits together, making it simpler to manage repairs and maintenance routines.

From the primary function to the tiniest details, a clear understanding of each component’s role enhances your ability to maintain or replace them when necessary. A comprehensive guide will walk you through common issues and give you the tools to fix them with confidence.

Understanding the Hudson Sprayer System

Effective maintenance and operation of any spraying device rely on a clear understanding of its internal mechanisms. Every machine consists of various interconnected elements, each serving a specific function to ensure the smooth application of liquid substances. Recognizing how these components work together helps improve the overall efficiency and durability of the equipment.

The system is designed to distribute liquids evenly and efficiently, with each part playing a role in this process. From the pump mechanism that generates pressure to the nozzle responsible for dispersion, each section must be carefully maintained. A solid grasp of how these pieces function will allow for better troubleshooting and more informed repair decisions.

Understanding the system’s flow, from the liquid reservoir to the final output, is key to diagnosing any issues. By studying the system’s design and structure, you can detect potential problems before they cause serious damage, ensuring optimal performance for an extended period.

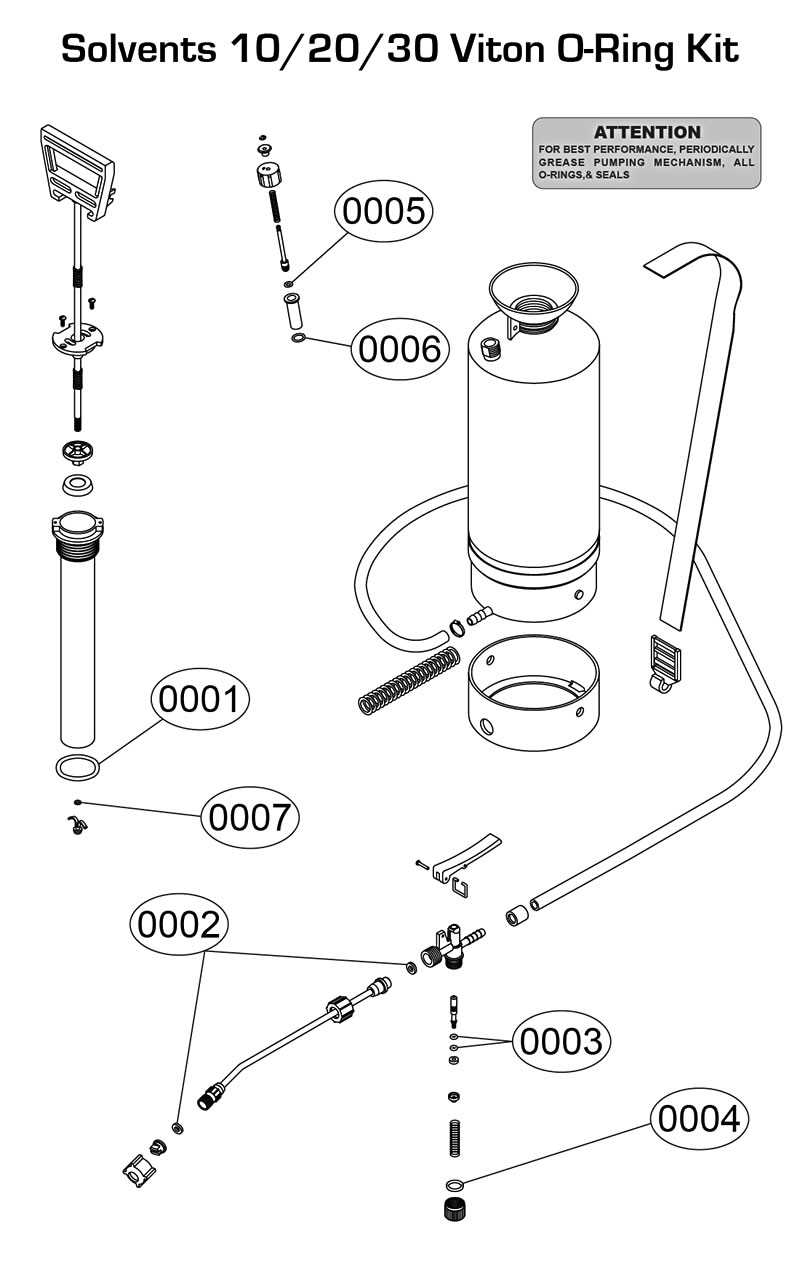

Identifying Key Components in the Diagram

Understanding the essential components of any equipment starts with recognizing the main elements that drive its functionality. Each device consists of several parts that work in harmony, ensuring proper operation. By identifying these key components, you gain a better understanding of how the system functions and how each piece contributes to the overall performance.

From the power source to the delivery mechanism, each element plays a vital role. For example, the mechanism responsible for generating pressure, the control valve that regulates flow, and the nozzle that disperses the liquid are just a few of the crucial parts you’ll encounter. Recognizing these pieces and their interactions is essential for both routine maintenance and troubleshooting.

Once you familiarize yourself with the layout of the components, it becomes easier to spot potential issues. By understanding where each part fits within the system, diagnosing problems and conducting repairs becomes more straightforward, allowing you to keep the equipment in optimal working condition.

Step-by-Step Guide to Repairing Parts

Repairing any mechanical system involves understanding the issue, identifying the faulty components, and taking the necessary steps to restore functionality. By following a clear, systematic approach, you can effectively resolve common malfunctions and ensure the equipment operates as intended. This section provides a detailed guide to help you repair individual components with ease.

Preparing for the Repair

Before starting any repair work, it is crucial to gather the necessary tools and materials. Ensure that the equipment is turned off and disconnected from any power sources to avoid accidents. Once you have the right tools, carefully inspect the system to identify which components need attention. Refer to the manual or component layout to confirm the specific part requiring repair or replacement.

Executing the Repair

After identifying the problematic area, follow these steps to fix it. Begin by disassembling the affected section carefully, making note of the order and arrangement of parts. Once the damaged component is accessible, either replace it with a new one or perform the required repair. Reassemble the system step by step, ensuring everything is securely reconnected. Finally, test the equipment to confirm that the issue has been resolved and the device functions correctly.