Having a clear understanding of the individual components of your firearm is essential for proper maintenance, troubleshooting, and repairs. Whether you’re an experienced enthusiast or a new owner, knowing how each part functions and interacts can greatly enhance your overall experience. This guide provides a detailed look at the key elements that make up your firearm, offering insights into their roles and importance.

Maintenance and repair become much easier when you can identify and comprehend the function of every piece. By studying the breakdown of your weapon, you can avoid costly mistakes and ensure its longevity. Properly assembling and disassembling the unit also reduces the risk of malfunctions and keeps the firearm in top condition.

Throughout this article, you’ll gain a better appreciation for the intricate mechanics behind your firearm, making it easier to perform necessary upkeep. Whether for professional or personal use, understanding these elements is crucial to ensuring your equipment functions reliably when needed the most.

Understanding the Taurus 856 Components

Every firearm is composed of a variety of elements, each serving a distinct function to ensure smooth operation and reliability. When it comes to proper handling and maintenance, having a clear understanding of these individual components is crucial. Knowing how each piece contributes to the overall performance allows users to maintain, repair, and troubleshoot more effectively.

Key elements within the firearm include the frame, trigger mechanism, firing pin, and barrel assembly, among others. Each part plays a specific role in the firing process and contributes to the firearm’s safety, accuracy, and longevity. For instance, the frame provides the structural support, while the firing mechanism ensures a smooth trigger pull and reliable ignition.

By gaining insight into how these components are interconnected, users can better appreciate the precision and engineering behind their weapon. This knowledge not only aids in basic upkeep but also enhances the ability to perform more complex repairs when necessary. Understanding these crucial pieces ensures that every part functions optimally, contributing to a safer and more enjoyable shooting experience.

How to Use the Taurus 856 Diagram

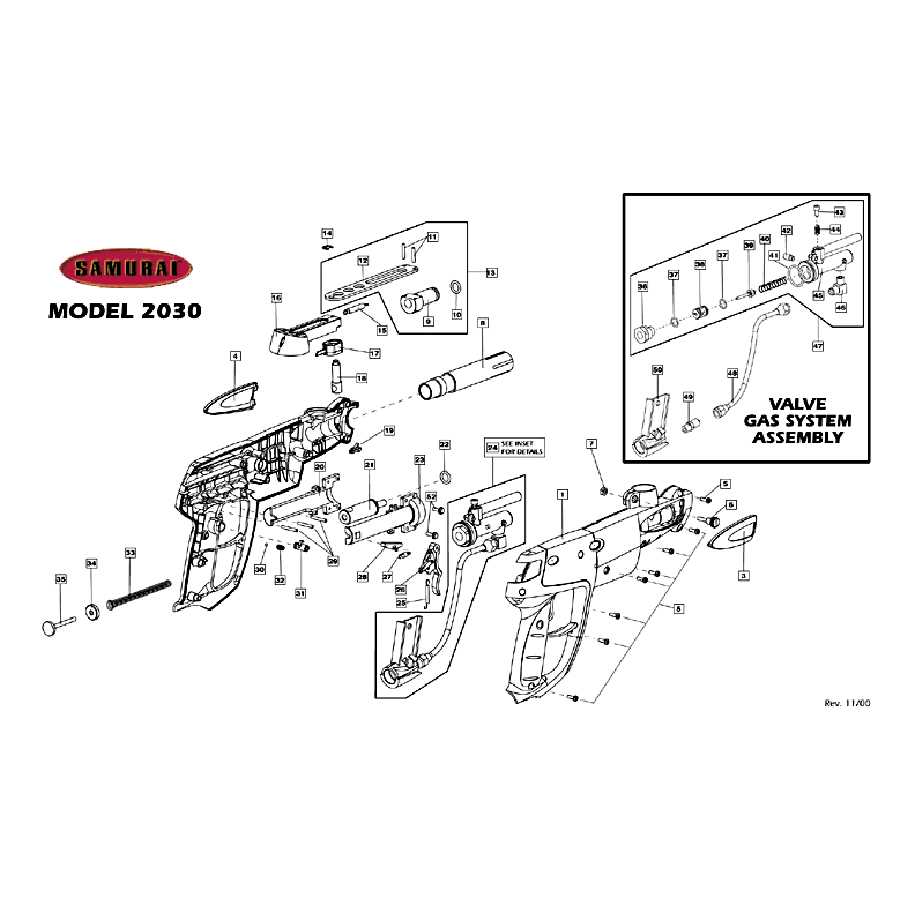

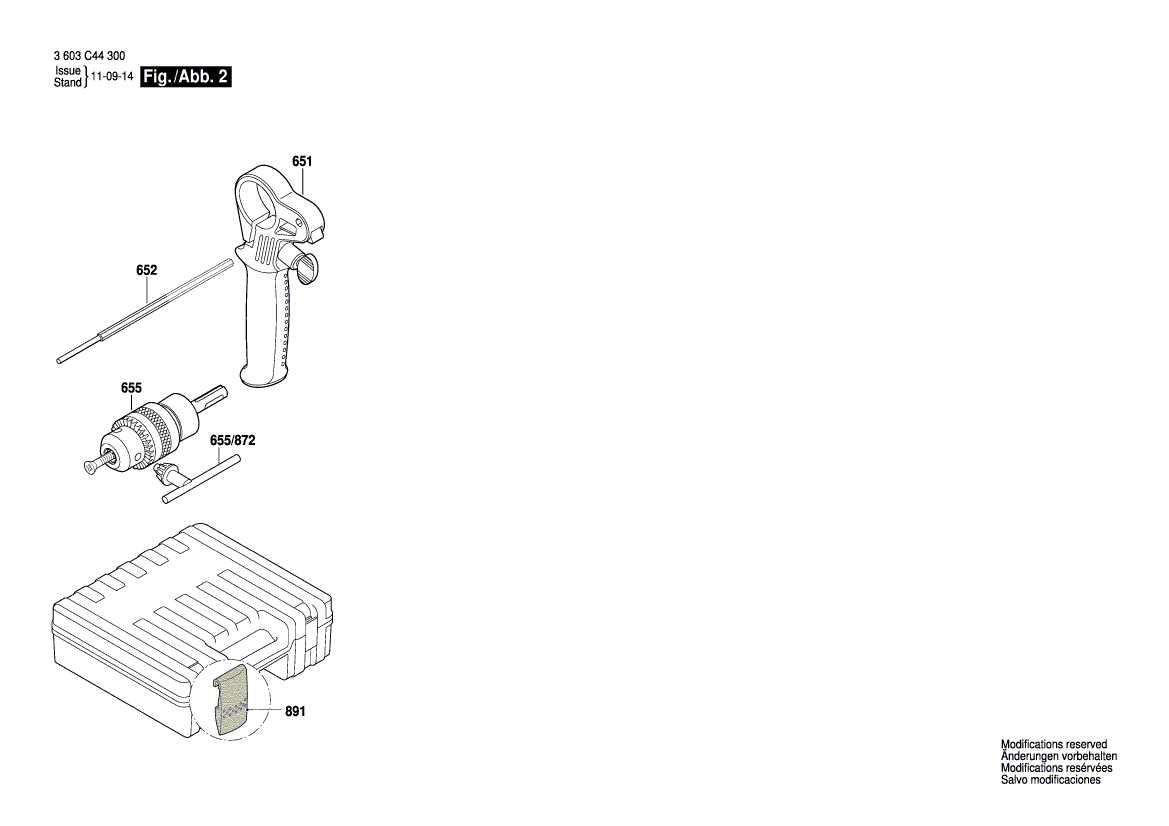

Knowing how to navigate a breakdown schematic of your firearm can significantly simplify maintenance and repairs. By referring to a detailed visual representation, you can quickly identify the individual components and understand their arrangement within the weapon. This can be especially helpful when diagnosing issues or assembling after disassembly.

The schematic is designed to give users a clear, organized view of each component, allowing you to spot wear, damage, or misplaced pieces. It’s essential to study the diagram carefully, starting from the central assembly and working your way outward. Each part is typically labeled, providing clarity on what is being depicted and how it functions in relation to other components.

Once you familiarize yourself with the layout, using the schematic becomes an invaluable tool during both repairs and routine cleaning. Whether you need to replace a worn component or simply check the alignment, this guide offers a quick and efficient way to ensure everything is in its proper place.

Common Repairs with Taurus 856 Parts

Proper maintenance ensures the longevity and reliability of your firearm. Over time, certain components may experience wear and require replacement. Understanding which parts commonly need attention and how to fix them will make repairs more efficient and help keep the weapon in top working condition.

Some of the most frequent repairs include:

- Firing Pin Replacement: The firing pin is a critical component that can wear down over time. If misfires occur, it might be necessary to replace it to restore proper function.

- Trigger Mechanism Adjustments: If the trigger feels stiff or unresponsive, cleaning or adjusting the trigger mechanism can often resolve the issue.

- Recoil Spring Maintenance: A worn recoil spring can affect cycling and performance. Replacing this spring is essential for smooth operation.

- Barrel Cleaning or Replacement: Regular cleaning of the barrel ensures accuracy and proper function. If accuracy decreases, the barrel might need to be replaced.

These repairs are part of standard firearm upkeep and can often be performed with minimal tools and expertise. However, when in doubt, always consult a professional to avoid further damage or safety issues. Regular inspection and maintenance will help prevent these common problems from becoming larger, more costly repairs.