Understanding the structure and functionality of various machine components is crucial for effective maintenance and repairs. Having a clear visual reference helps in identifying parts and understanding how they interact within the system. This section provides an insightful overview of the core elements that make up a reliable machine, helping operators and technicians make informed decisions when servicing equipment.

Proper identification of each element ensures smooth operation and minimizes downtime. By following a well-organized layout, it becomes easier to pinpoint the correct components for replacement or inspection. This not only extends the lifespan of the equipment but also contributes to efficient performance in the long term.

Understanding Key Components of the Machine

To effectively maintain and troubleshoot complex machinery, it is essential to comprehend the roles and functions of each integral component. These elements work in unison to ensure smooth operation, and understanding their purpose is the first step in identifying potential issues or necessary repairs. Each part contributes to the overall performance and efficiency, requiring proper knowledge for effective handling.

Familiarity with the layout and functionality of each section helps operators quickly assess and address any concerns that may arise. Recognizing how the individual components interact provides a solid foundation for maintenance strategies. Furthermore, this understanding aids in minimizing errors and optimizing machine longevity, making it a critical aspect for any technician or user.

Systematic inspection of the components, along with a detailed grasp of their interactions, ensures reliable operation and can prevent costly downtime. Regular assessments are crucial for preserving the integrity of the machinery and guaranteeing its readiness for future tasks.

Identifying Key Parts for Maintenance

Proper maintenance begins with recognizing the most crucial components of any system. Understanding which elements are vital for the overall functionality allows for targeted inspections and timely repairs. Regular checks on these parts help prevent breakdowns and ensure optimal performance, reducing the risk of costly issues down the line.

Critical Elements to Monitor

Among the various components, some require more frequent attention due to their high usage or susceptibility to wear. These include moving parts, electrical connections, and systems responsible for power transmission. Knowing which parts are under more stress allows for focused maintenance, improving the lifespan and efficiency of the machine.

Signs of Wear and Tear

Identifying early signs of wear is essential for preventing system failure. Common indicators include unusual noises, visible damage, or a decrease in performance. Regular monitoring and replacing components before they fail completely can significantly extend the operational life of the equipment.

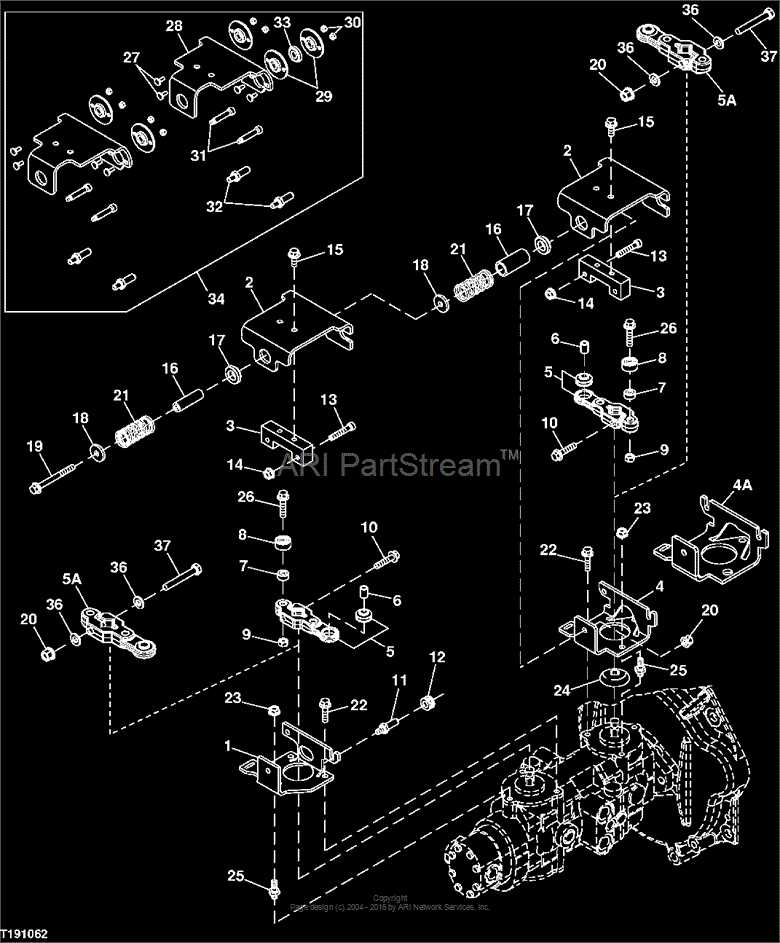

Step-by-Step Repair with Visual Guide

Repairing a machine effectively requires a clear, structured approach that ensures each step is followed accurately. A visual guide, showcasing the arrangement and function of various components, is invaluable during this process. It simplifies the identification of faulty parts, helping technicians and users perform repairs confidently and efficiently.

Preparation for Repair

The first step in any repair is preparation. This includes gathering necessary tools, understanding the machine’s structure, and ensuring safety measures are in place. Before starting the process, it’s essential to inspect the equipment thoroughly, identifying the components that require attention. Knowing which sections to focus on makes the repair process smoother and more efficient.

Executing the Repair Process

Once the preparation phase is complete, the repair process begins with the disassembly of the problematic area. Carefully follow the instructions provided in the visual guide to remove faulty components and replace them with new ones. Take your time to ensure each part is correctly positioned, and double-check all connections for stability and safety.