Understanding the structure and individual elements of mechanical equipment is crucial for proper maintenance and repair. A detailed overview of the unit’s internal configuration can make it much easier to identify specific components and troubleshoot potential issues. This guide provides an in-depth look into how each section fits together and contributes to the overall performance.

For anyone working with this machinery, having a clear visual reference of its internal components is an invaluable tool. By following a well-structured map of connections and fittings, users can better navigate through assembly and disassembly procedures, ensuring accurate repairs and replacements.

Knowledge of the system’s layout is essential for smooth operation and extended durability. With the right approach, you can maximize the effectiveness of repairs and minimize unnecessary downtime. The following sections will help break down the key elements involved and offer practical insights into their functions.

Understanding the Stihl TS 700 Parts

When working with complex machinery, a clear understanding of its components is vital for efficient operation and troubleshooting. Each element plays a significant role in ensuring the system runs smoothly, and knowing how these parts interact can save time and effort during repairs and maintenance. This section aims to provide insights into the key elements of the equipment and their functions.

Critical Elements of the Assembly

At the core of the equipment’s design is a range of interconnected components, each serving a unique purpose. From the engine system to the cutting mechanism, every part has been designed to work in harmony. A deep understanding of these components allows for a quicker diagnosis of issues and a more effective approach to fixing any malfunction.

Maintenance and Repair Considerations

Knowing the structure of the machine is not just about identifying parts–it’s about ensuring their longevity through proper care. Regular checks, correct installation, and replacement of worn elements help maintain the machine’s performance over time. Recognizing the wear and tear signs of each key piece ensures that it functions optimally throughout its lifespan.

Detailed Breakdown of TS 700 Components

Understanding the intricate details of machinery components is essential for effective operation and maintenance. Every piece within the assembly contributes to the overall function, and recognizing their specific roles is key to both performance and longevity. This section delves deeper into the primary sections of the equipment and their unique characteristics.

The mechanical system consists of several crucial elements, including the power source, drive components, and cutting mechanisms. Each element is designed to serve a distinct function, whether it’s generating force, directing movement, or performing the cutting action itself. A clear understanding of how these components work together allows for quicker repairs and better long-term use of the equipment.

Regular inspection of the individual parts helps detect wear or damage early on, ensuring that potential issues are addressed before they affect the machine’s overall performance. Proper maintenance is crucial for preserving the integrity of the system, especially in high-demand situations. With a comprehensive understanding of these key elements, users can easily perform troubleshooting, replacements, and repairs when necessary.

How to Use the Parts Diagram Effectively

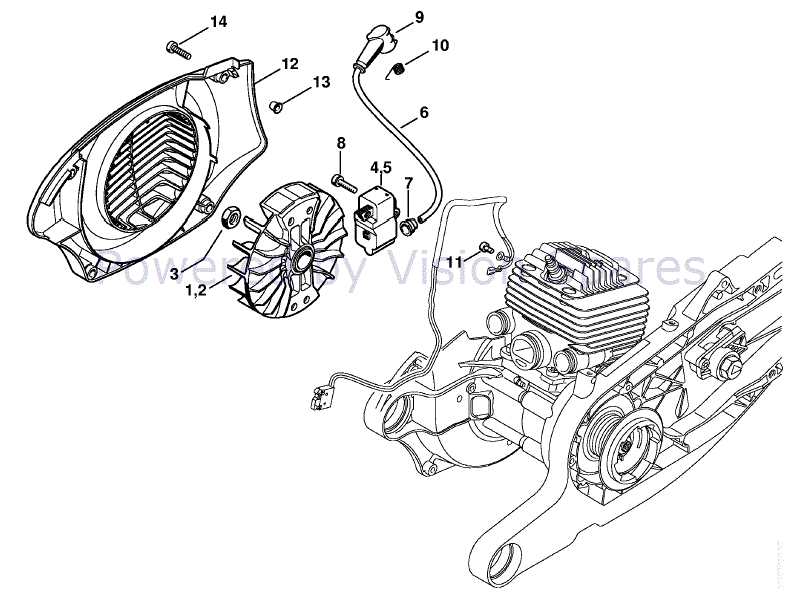

Having a clear visual reference of a machine’s internal layout is essential for anyone working with mechanical equipment. These illustrations provide valuable insights into the arrangement and connection of various components. Knowing how to interpret these images accurately allows for more efficient assembly, troubleshooting, and repairs.

To use these references effectively, begin by familiarizing yourself with the different sections of the machine. Pay close attention to the labels, part numbers, and positioning of each element. This helps ensure you can quickly locate the components you need when performing maintenance or replacing parts. Understanding the flow of the system also aids in identifying potential issues or weak points.

Additionally, always cross-reference the visual guide with the manufacturer’s manual. This ensures that the correct parts are being used and placed in the proper order, minimizing the risk of errors. By following a structured approach and keeping the reference handy during repairs, you can streamline your process and improve the accuracy of your work.