When working with complex machinery, having a clear understanding of its individual elements is crucial for maintenance and repair. Knowing how the different parts are connected and function together helps in troubleshooting and ensuring the equipment runs smoothly. Properly identifying and handling each part can extend the lifespan of the machine and reduce downtime.

The guide will walk you through the essential components of a typical construction vehicle, highlighting their roles and interconnections. Whether you’re a professional mechanic or an operator, this information can assist in daily operations and emergency repairs.

Familiarizing yourself with these essential components and their layout not only improves your repair skills but also enhances overall efficiency on the job site. Understanding the visual map of these elements makes it easier to identify issues and take quick action.

Understanding Heavy Equipment Components

For effective maintenance and operation of construction machinery, it is essential to comprehend the various elements that make up the vehicle. Each component plays a critical role in the overall performance and durability of the machine. Familiarity with how the system functions can help prevent issues and improve troubleshooting skills.

Key Elements of the Vehicle

The primary elements include the engine, hydraulics, transmission, and structural framework. Each of these systems is integral to the machine’s function. Understanding their layout and interaction is necessary for proper maintenance and repair. Regular inspections and knowing where each component is located will save time and effort during operations.

Common Issues and Solutions

Without proper care, even the most durable machinery can encounter problems. Common issues may include wear and tear on the engine or hydraulic system. Early detection of these issues ensures a quicker response and reduces the chance of extensive damage. Routine checks are key to identifying problems early and maintaining the machinery’s efficiency.

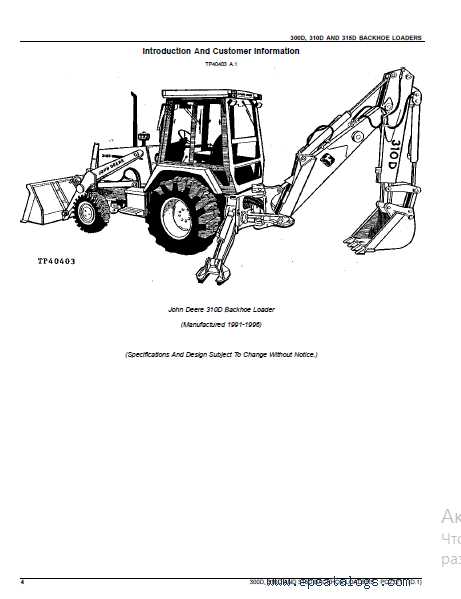

Key Components of the 310D Backhoe

The efficient functioning of heavy machinery relies on a series of interconnected elements. These elements, when properly maintained, ensure the machine performs at its best, delivering power and precision across various tasks. The following sections highlight some of the core components that contribute to the optimal operation of this versatile construction equipment.

Hydraulic System

The hydraulic system plays a crucial role in enabling movement and lifting capabilities. It powers key mechanisms such as the bucket and arm, allowing for smooth operation and adaptability in different digging or lifting tasks. Proper maintenance of this system is essential to prevent leaks and maintain the pressure required for efficient operation.

Engine and Transmission

The engine and transmission work in tandem to provide the necessary power to the machine. The engine delivers the energy required for various functions, while the transmission ensures the appropriate speed and torque are applied to the wheels or tracks. Regular checks of these components help maintain the performance and longevity of the equipment.

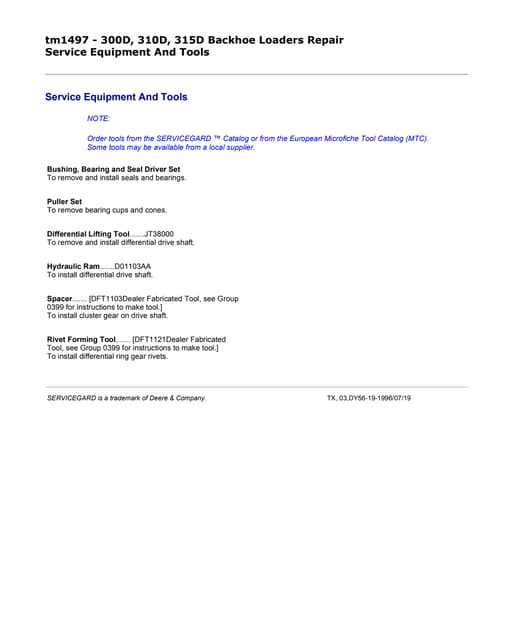

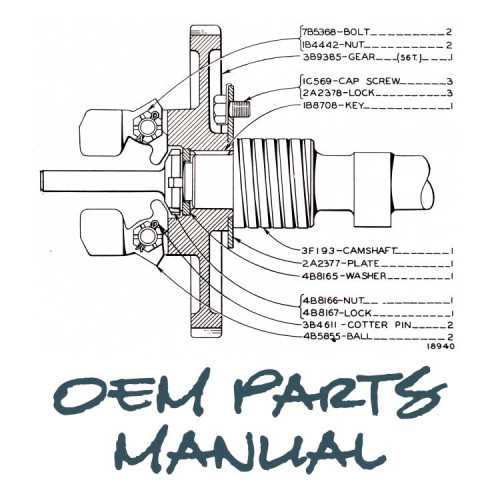

How to Use the Parts Diagram Effectively

Understanding the layout and structure of a mechanical layout is essential for maintenance and repairs. A well-organized visual representation can be a valuable tool, providing clarity on the components and their placement within the machine. Knowing how to interpret these illustrations ensures that tasks are completed accurately and efficiently, reducing errors and downtime.

Identifying Key Components

The first step in utilizing the schematic is to familiarize yourself with the major components and their functions. Pay attention to labels, part numbers, and connections between different elements. By focusing on these details, you can quickly locate specific parts and understand their roles in the overall system, streamlining your maintenance efforts.

Understanding Relationships Between Parts

Once the key components are identified, the next step is to study how they interact with one another. Pay particular attention to connections, fasteners, and the flow of power or fluid. Understanding these relationships will help in troubleshooting issues, as it allows you to pinpoint which parts may be causing malfunctions and need attention.