Every household appliance plays a vital role in simplifying daily tasks. Understanding the different elements within these machines can make maintenance and repairs more manageable. When it comes to GE laundry equipment, having a clear understanding of its internal structure can help users troubleshoot and extend the lifespan of their appliance.

By familiarizing yourself with the various mechanisms inside your GE unit, you’ll gain insight into how they work together to ensure effective performance. Whether you’re dealing with a malfunction or simply performing regular upkeep, knowing the key components and their functions is crucial for successful maintenance.

Detailed knowledge of each element empowers you to diagnose issues swiftly and make informed decisions regarding repairs or part replacements. This guide will provide essential details, helping you to better navigate your appliance’s system and address any concerns that may arise.

Understanding GE Laundry Appliance Components

The internal structure of any appliance can be complex, but a clear understanding of its various elements is essential for smooth operation. In the case of GE laundry equipment, recognizing how different components interact ensures that the machine functions optimally. Each part has a specific role, and when these parts work together, they contribute to the efficient performance of the unit.

Key Mechanisms for Efficient Operation

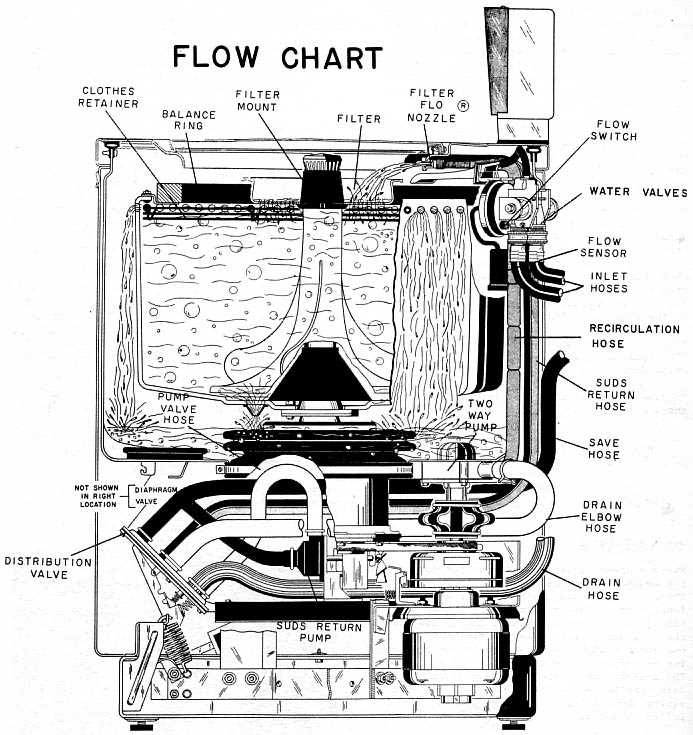

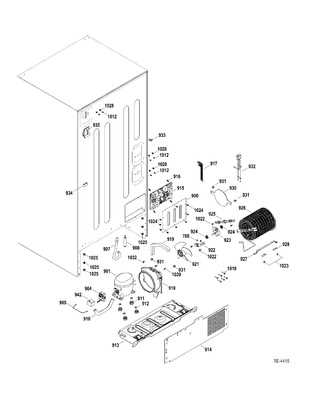

At the heart of the system, several key mechanisms help achieve the desired results. Motors, belts, and sensors work in unison to deliver the necessary power, while the water intake and drainage systems ensure cleanliness and efficiency. Understanding how these mechanisms connect and function can help in identifying common issues.

Maintaining Long-Term Performance

Proper maintenance of these elements is crucial for long-term performance. Regular cleaning, lubrication, and timely replacements can prevent early wear and tear, enhancing the longevity of the equipment. Familiarity with the functions of each component allows for quick diagnosis and easy fixes when issues arise.

Key Parts of a GE Washer Explained

The efficient functioning of any laundry machine relies heavily on its various internal components. Each element plays a unique role in ensuring the appliance delivers optimal results, from the motor to the drum. Understanding these components allows for better maintenance and troubleshooting when needed.

Motor and Drive System

The motor is the powerhouse of the system, responsible for driving the drum’s rotation. It connects to the drive belt, which transfers power to the drum, enabling it to spin and agitate. The motor’s performance is crucial for efficient washing and drying cycles.

Water and Drainage System

The water system, including the inlet valve and drain pump, ensures the proper intake and expulsion of water during the wash. The inlet valve controls the flow of water into the appliance, while the drain pump expels used water after each cycle. A well-functioning water system is vital for effective cleaning and draining.

How to Identify Washer Malfunctions

Recognizing the signs of a malfunction in your appliance is crucial to address issues before they escalate. Common symptoms like unusual noises, water leakage, or failure to complete cycles often point to specific internal problems. By understanding these indicators, users can pinpoint the root cause and take appropriate action.

Listen for any irregular sounds, such as grinding or buzzing, which may indicate problems with the motor or drive components. If the machine fails to drain or fill properly, the issue could lie within the water intake or drainage system. Identifying these signs early can help prevent further damage and ensure smooth operation.