Maintaining machinery in optimal working condition is essential for ensuring long-term performance. Understanding the layout and structure of your equipment can help simplify repairs and routine checks. A clear visual representation of all key elements can save time and prevent costly mistakes during maintenance tasks.

In this guide, we will explore how to read and interpret an equipment layout for efficient maintenance and repair. By recognizing the critical components, you can identify potential issues early and make informed decisions when replacing or fixing parts. This resource is designed to make the process straightforward and accessible for both experienced technicians and newcomers alike.

With this knowledge, you will be able to confidently navigate the maintenance needs of your machinery, ensuring it runs smoothly for years to come.

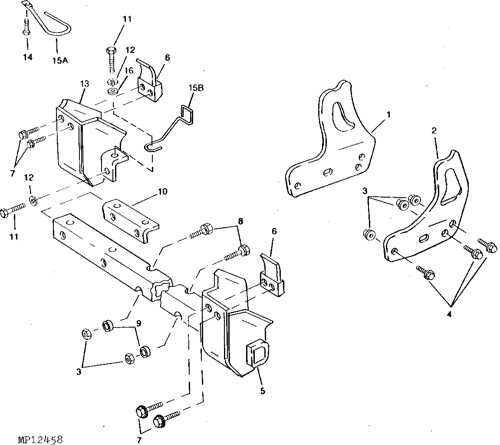

Understanding the Tractor Component Layout

When working on any heavy machinery, knowing the placement and function of each individual component is crucial for effective repairs and maintenance. A well-organized visual layout can serve as a valuable reference, helping you identify different sections and critical parts with ease. This knowledge allows for more accurate troubleshooting and ensures that every component receives the attention it requires.

Key Sections and Their Functions

At the heart of any layout are the key sections that contribute to the overall functionality of the equipment. These areas typically include the engine, drivetrain, hydraulic system, and the electrical components. By breaking down the machine into its main sections, it becomes easier to understand how each part works together to keep the entire system running smoothly.

Benefits of a Clear Layout

A detailed representation not only helps with identifying individual components but also assists in understanding their interconnections. This allows for quicker diagnostics and more efficient repairs. Furthermore, it minimizes the risk of overlooking vital parts that could cause significant issues if neglected.

How to Identify Key Components on the Layout

Recognizing the essential elements of any machinery is vital for efficient maintenance. A clear and accurate visual guide can help pinpoint where each critical component is located, making it easier to perform repairs or replacements when necessary. By understanding how to read such a guide, you’ll be able to quickly identify problem areas and address them with confidence.

The first step in identifying key elements is to familiarize yourself with the overall structure. Most guides will label sections such as the engine, transmission, and hydraulic system, which are typically the most crucial parts of any piece of equipment. Once you understand the general layout, look for specific symbols or color codes that indicate unique parts like belts, filters, or valves.

Pay attention to reference numbers or part codes that are often used to differentiate between components. These numbers will help you cross-reference the layout with part catalogs or manuals, ensuring that you get the correct replacement or maintenance tools for the job.

Essential Tips for Maintaining Your Tractor

Regular upkeep is key to extending the lifespan and performance of your equipment. Following a proper maintenance routine ensures that all systems are working as intended, reducing the risk of unexpected breakdowns and costly repairs. Knowing the right steps to take can help prevent major issues and keep your machine running smoothly throughout the seasons.

Start with routine inspections. Before using the machinery, always inspect vital components such as the engine, belts, and fluid levels. Regularly checking for wear and tear will allow you to catch potential problems early, preventing further damage and ensuring optimal performance.

Clean and lubricate moving parts. Keeping parts clean and well-lubricated is crucial for avoiding friction and reducing the chance of mechanical failure. Pay special attention to the drivetrain, suspension, and hydraulics. Proper lubrication not only ensures smoother operation but also reduces wear over time.

Follow a strict maintenance schedule. Each machine has its own recommended service intervals, from oil changes to filter replacements. Stick to these schedules to keep everything in top condition. Don’t skip maintenance tasks, as neglecting them can lead to more significant issues down the road.

Lastly, always refer to your machine’s manual or reference materials for guidance. Whether it’s checking fluid levels or adjusting settings, following manufacturer recommendations will ensure your equipment stays in peak condition for years to come.