When working with everyday office or industrial equipment, knowing how each element functions can make a significant difference in efficiency and longevity. These tools are made up of several interconnected elements that work in harmony to deliver smooth performance. Understanding the role of each component ensures not only effective operation but also easy troubleshooting and maintenance.

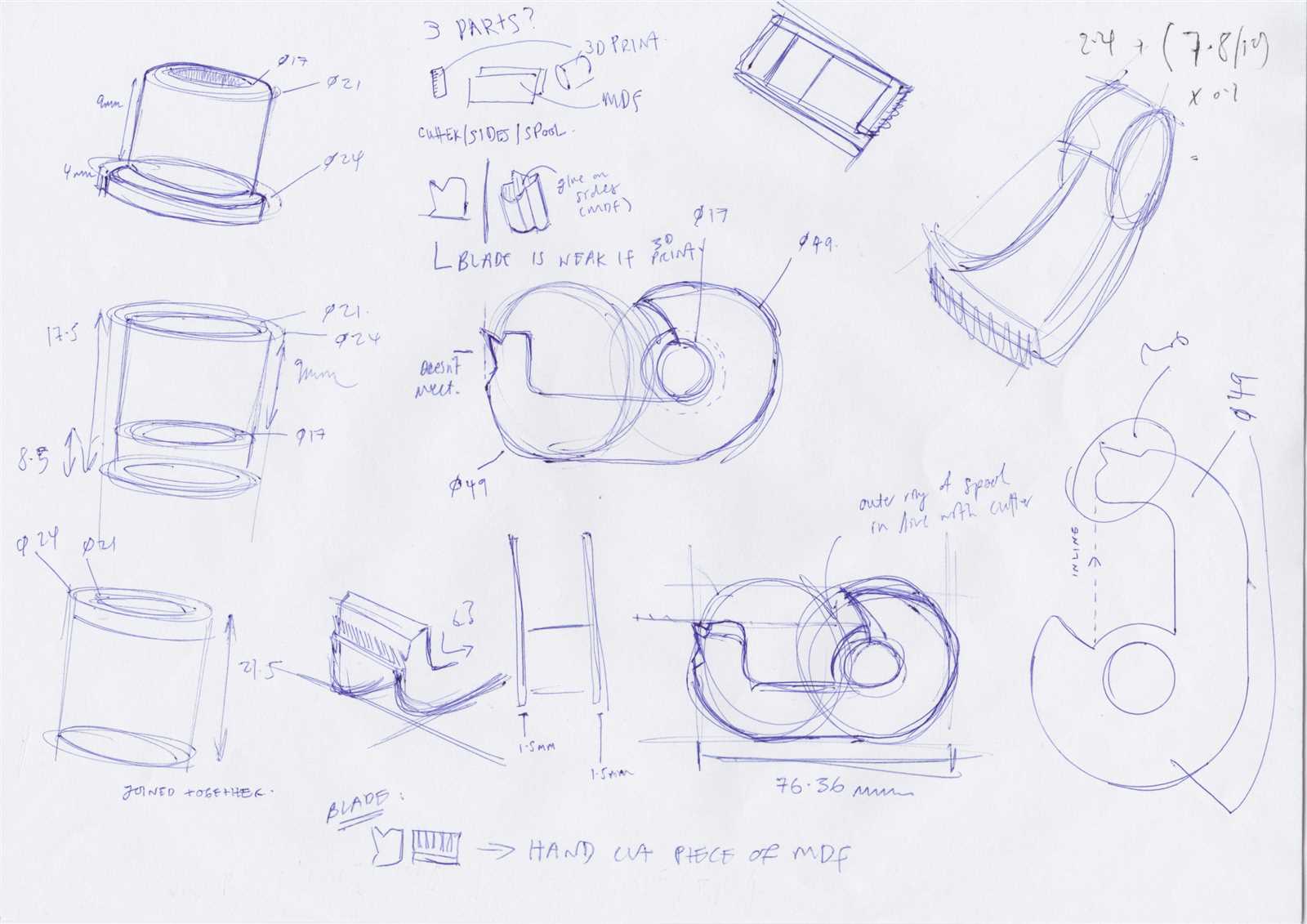

Breaking down the tool’s structure into its individual components allows users to gain a deeper understanding of how these parts work together. Each element, whether mechanical or functional, plays a unique role in the tool’s overall performance. Familiarity with their specific functions will help in identifying issues and making necessary repairs.

Proper knowledge of these components can also prevent costly repairs by promoting timely maintenance. By observing how the tool’s pieces interact, users can optimize its use and increase its lifespan, making it a valuable asset in various settings.

Tape Dispenser Components Breakdown

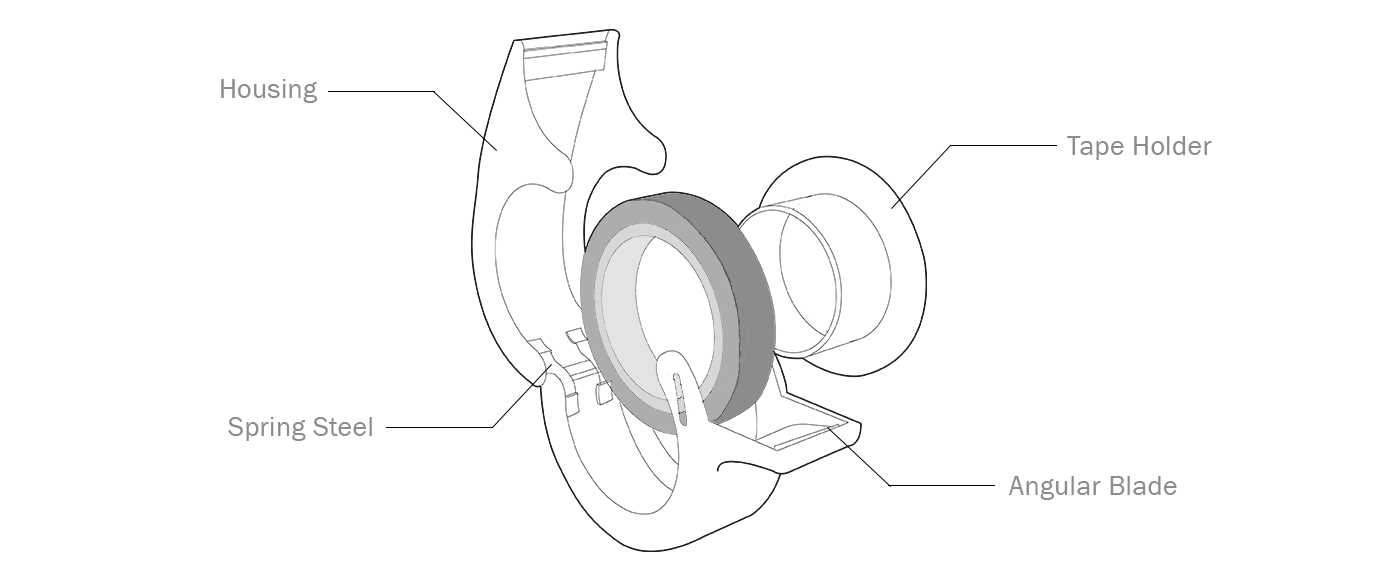

Understanding the structure of a common office tool is essential for effective use and maintenance. This device is made up of various elements, each playing a crucial role in its operation. These parts work together seamlessly to ensure smooth functionality, from the initial setup to everyday use. Knowing how these components interact can improve performance and simplify repairs when necessary.

The core elements typically include a housing that holds everything in place, a mechanism that controls the movement, and a cutting tool for precise operation. Each of these pieces contributes to the overall effectiveness of the device, making it reliable for frequent tasks. Whether it’s the spring-loaded section that ensures tension or the guiding mechanism that aligns the roll, each part is vital to its smooth operation.

When properly assembled and maintained, this tool can provide long-lasting service. Understanding the role of each component not only aids in troubleshooting but also allows users to identify areas for improvement, contributing to a more efficient and cost-effective working environment.

Understanding the Function of Each Part

Each element of an office tool has a specific role that contributes to its overall functionality. By understanding how each component operates, users can gain better control over the tool, ensuring it performs efficiently and reliably. The following breakdown highlights the essential functions of the key components:

- Base: The foundational structure that provides stability, ensuring all other elements are securely held in place.

- Guiding Mechanism: Helps align the material, making sure it feeds out smoothly and consistently.

- Cutting Edge: Responsible for cleanly severing the material, ensuring a neat and precise cut every time.

- Roll Holder: Keeps the material securely in place, allowing it to roll out with controlled tension.

- Tension Control: Maintains the correct tension to prevent the material from rolling too freely or too tightly.

Each component is designed to work in harmony with the others, contributing to the overall efficiency and reliability of the tool. Whether you are using it for occasional tasks or daily operations, recognizing the function of each element will enhance your ability to use the device effectively and maintain it in optimal condition.

How to Identify Tape Dispenser Parts

Recognizing the components of an office tool is key to understanding its function and troubleshooting any issues that may arise. Identifying the individual elements requires a closer look at the structure and how each part contributes to the overall operation. By familiarizing yourself with these elements, you can easily determine which component may be causing a malfunction or require maintenance.

The first step in identifying the components is to observe the general structure of the tool. Focus on the main body, which typically houses most of the other parts. Look for specific features like the tension control, which may appear as a knob or lever, and the cutting edge, usually positioned near the feeding mechanism. Additionally, the roll holder and guiding system can be identified by the way the material is fed through and positioned for use.

Once you have a basic understanding of the tool’s design, it’s important to pay attention to any distinguishing marks or labels that might indicate specific components. Many tools have small identifiers or shapes that differentiate parts with specific functions. By noting these details, you can quickly recognize the part’s purpose and whether it needs attention.

Common Issues and Solutions

Like any frequently used tool, common issues can arise over time that may affect its performance. Recognizing these problems early can prevent further damage and ensure smooth operation. Understanding the root causes of these issues and knowing how to address them can help keep the device functioning at its best.

Difficulty in Cutting

If the material isn’t cutting cleanly, it may be due to a dull or misaligned cutting edge. In some cases, debris may accumulate around the blade, preventing a smooth cut. Solution: Clean the cutting edge carefully and check if it’s properly aligned. If the blade is worn, replacing it with a new one can restore the tool’s effectiveness.

Material Not Feeding Properly

When the material doesn’t feed smoothly, it could be caused by improper tension or a jammed guiding mechanism. This can make the operation difficult and frustrating. Solution: Ensure that the tension control is set correctly and that there is no obstruction in the guiding system. If the material is tangled, carefully untangle it and reset the mechanism.

Addressing these issues promptly will extend the lifespan of the tool and maintain its functionality for everyday tasks.

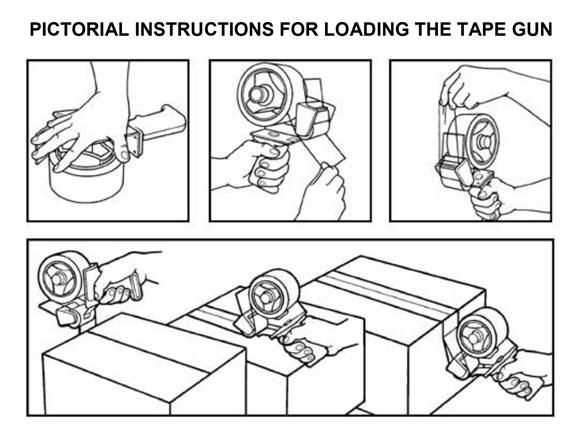

Step-by-Step Guide to Assembling Parts

Assembling a tool requires careful attention to the order in which the components are put together. Following a clear, methodical process ensures that each part is securely connected and functions as intended. This guide will take you through the steps to properly assemble the essential elements of the device, ensuring smooth operation from the start.

| Step | Action | Details |

|---|---|---|

| 1 | Secure the Base | Begin by placing the main housing on a flat surface. This provides the foundation for the other components. |

| 2 | Install the Roll Holder | Position the holder inside the base. Ensure it is aligned and locked into place to support the roll properly. |

| 3 | Attach the Tension Mechanism | Connect the tension control system to the base, making sure it functions smoothly and adjusts the material’s movement. |

| 4 | Place the Cutting Blade | Position the cutting edge in its designated slot. Ensure it is securely attached and free of obstructions. |

| 5 | Check Alignment | Verify that all components are aligned correctly. Adjust as needed to ensure everything functions without interference. |

By following these steps, you can easily assemble the tool, ensuring that each element is securely positioned for optimal performance. Proper assembly not only enhances efficiency but also reduces the likelihood of malfunctions during use.