Understanding the intricate design and function of modern agricultural machinery is essential for effective operation and maintenance. Each machine consists of numerous interconnected elements, all playing specific roles to ensure smooth performance. By breaking down the system into individual parts, it becomes easier to troubleshoot, repair, and maintain your equipment, ensuring longevity and efficiency.

Maintenance of these components is a critical aspect of machinery upkeep. Identifying wear and tear early can prevent costly repairs and downtime. This guide will explore the essential components of the system, providing clear insights into their function and location, helping you stay informed about the inner workings of your equipment.

Whether you’re a professional in the field or a hobbyist, understanding the detailed construction of your machine enables better decision-making during maintenance. Knowing where each component fits within the overall system is key to keeping everything in optimal condition.

Understanding the Tractor Attachment System

The modern agricultural machine features a sophisticated system designed to facilitate quick and efficient attachment and detachment of implements. This system is engineered to save time and enhance the operator’s ability to switch tools with minimal effort, ensuring smooth workflow in various farming tasks.

The connection mechanism involves a series of components that work together to securely attach and disengage implements. Understanding the layout and function of each element within the system is crucial for proper maintenance and troubleshooting. The ease of use and reliability of this setup significantly improve overall operational efficiency.

Regular inspection and maintenance of the connection system ensure that all elements function properly and last longer. Knowledge of the system’s components allows users to detect potential issues early, minimizing downtime and preventing costly repairs. Proper handling and understanding of these parts are key to maintaining a highly effective and durable system.

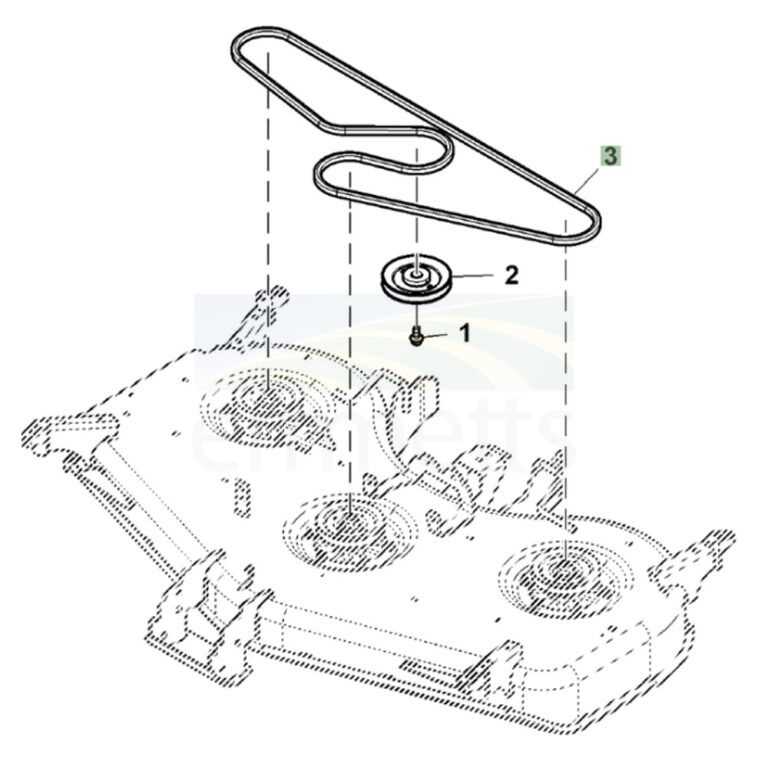

Key Components of the 60D Model

The tractor attachment system includes several critical elements that allow seamless operation and reliable performance. Each component plays a unique role in ensuring smooth interaction between the machine and the implement. Understanding these individual parts is essential for effective troubleshooting and maintenance.

Connection Mechanism

The primary function of the connection system is to securely attach and release implements. This mechanism involves locking and unlocking features that facilitate quick and efficient swaps between tools, ensuring that the user can change implements with ease. Regular maintenance of these connection components is vital to ensure their longevity and proper functioning.

Hydraulic and Support Systems

Hydraulic systems are integral to the efficient operation of the entire setup. These components manage the pressure required to lift and position the implements, ensuring accurate alignment and stability during use. A strong and well-maintained hydraulic system is crucial for the overall effectiveness of the attachment system, especially in heavy-duty tasks.

Maintenance Tips for Attachment System Components

Proper care and maintenance of the components involved in the attachment system are essential to ensure smooth performance and prevent costly repairs. Regular attention to these critical elements can significantly extend the lifespan of your machinery and keep it functioning at its best. By following simple maintenance steps, operators can avoid downtime and ensure optimal efficiency during operation.

Inspecting the Connection Mechanism

The connection system is subjected to wear and tear during frequent use. It is crucial to inspect the locking mechanisms and connectors for any signs of damage or corrosion. Lubricating moving parts and ensuring that locking pins are free of debris will help maintain smooth operation and prevent rust buildup, which can hinder performance.

Hydraulic System Maintenance

The hydraulic system plays a vital role in lifting and positioning implements. Regularly check hydraulic hoses, seals, and fluid levels to ensure proper functioning. Over time, hydraulic fluids can degrade, so changing the fluid as recommended by the manufacturer is essential to avoid pressure loss and system failure. Tightening connections and inspecting for leaks can prevent unnecessary hydraulic system issues.