When maintaining outdoor machinery, understanding the components and their connections is crucial. Properly identifying each element ensures that repairs and replacements can be made efficiently, keeping your equipment in optimal working condition.

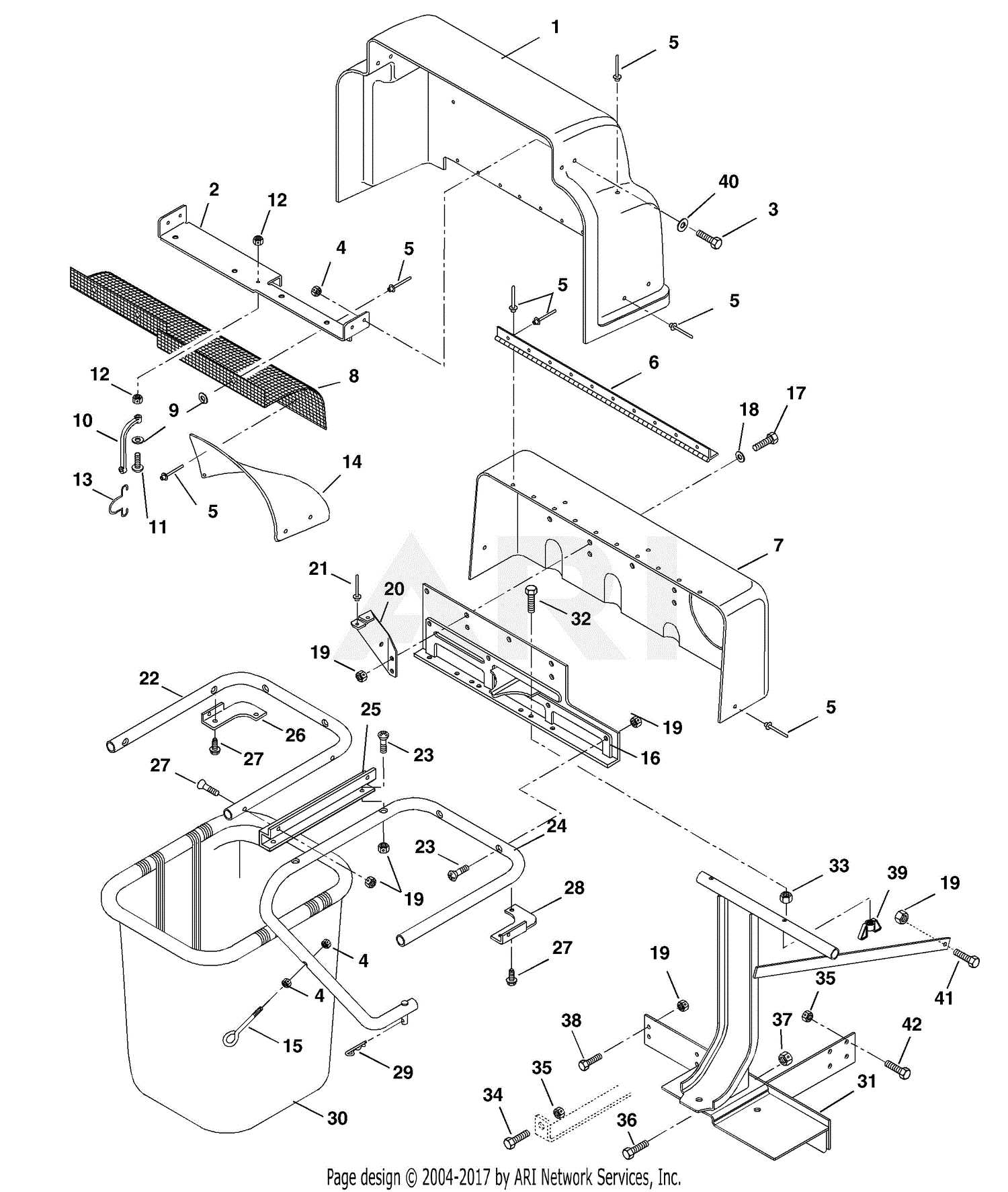

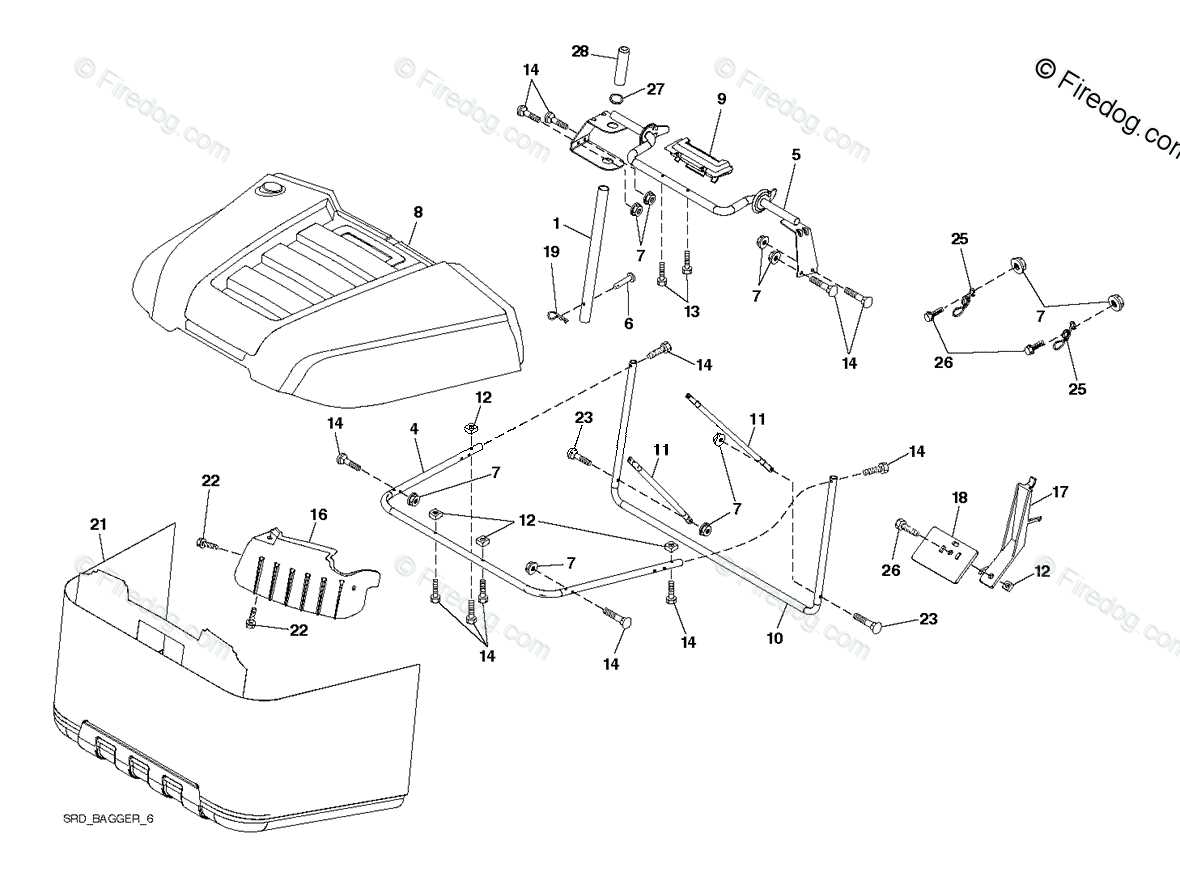

Visual representations of mechanical systems play a key role in simplifying this process. These illustrations offer a clear view of how each part fits together, helping users troubleshoot and address common issues with ease.

Whether you’re replacing worn-out components or conducting routine maintenance, knowing the structure and function of each piece will improve your ability to handle repairs and prolong the life of your machine.

Understanding Lawn Equipment Components

In order to properly maintain outdoor machinery, it is essential to have a clear understanding of the individual elements that make up the system. Each component plays a specific role in ensuring the overall functionality and efficiency of the machine. Identifying these pieces and knowing their functions can greatly simplify repair and maintenance tasks.

Key Elements of the System

Every machine is made up of various mechanical pieces, each serving a distinct purpose. For example, the collection system typically includes a hopper for holding debris and a conveyor system to transport materials. Understanding how these work together helps in troubleshooting issues and ensuring the machine performs as expected.

Commonly Replaced Components

Some components, due to wear and tear, are more likely to need replacement over time. Drive belts and filters are among the most commonly replaced items. Knowing where these parts are located and their role in the system can save time during repairs and ensure proper functionality after replacements.

How to Read a Lawn Equipment Schematic

Understanding technical drawings of machinery can significantly improve your ability to maintain and repair equipment. These illustrations provide a detailed view of the machine’s components, showing how they are connected and their specific functions within the system. Reading these schematics correctly allows for efficient problem-solving and accurate replacement of components.

Interpreting Symbols and Labels

Each part of the schematic is represented by specific symbols and labels. Familiarizing yourself with these conventions is the first step in understanding the diagram. Parts are often labeled with numbers or codes, and these references help identify the exact components in the system. Knowing what each symbol stands for can make reading the schematic straightforward and less overwhelming.

Identifying Relationships Between Components

The schematic illustrates how different pieces work together within the machine. Connections between parts are often shown with lines, which can indicate physical links or flow paths. Understanding these relationships helps identify potential issues, such as clogged pathways or malfunctioning links between parts.

Common Issues with Lawn Equipment Components

Outdoor machinery can experience a variety of issues due to the wear and tear of its individual elements. Recognizing these common problems early on helps prevent larger breakdowns and costly repairs. Familiarity with typical malfunctions allows users to troubleshoot efficiently and replace affected parts before they cause more damage.

Clogging and Obstructions

One of the most frequent issues involves the buildup of debris, which can cause blockages in the system. Hoppers, conveyors, and hoses are particularly susceptible to clogs, especially when they are not regularly cleaned. Obstructions can reduce the machine’s efficiency and, if left unchecked, may damage the components.

Worn-Out Belts and Filters

Another common problem is the deterioration of drive belts and filters. Belts may become loose or snap due to constant friction, while filters can become clogged and ineffective over time. Regular inspection and replacement of these components are essential to maintain optimal performance.