When working with complex machinery, knowing how each individual component fits into the overall structure is crucial for effective maintenance and repairs. A clear representation of the parts and their placement can save time and effort when troubleshooting or replacing worn-out pieces. Understanding the assembly layout not only enhances the repair process but also ensures that everything is reassembled correctly, preventing potential damage during operation.

Efficient repairs depend on the ability to identify each component quickly. Whether you are replacing a broken part or performing routine maintenance, having a detailed reference at hand can simplify the process. The proper understanding of the mechanical structure allows for accurate identification of faults and ensures that parts are replaced with precision.

Utilizing a well-organized guide offers significant advantages, especially for those unfamiliar with intricate machinery. It aids in visualizing the connections between different parts, ensuring that each piece serves its intended function. This approach not only promotes timely repairs but also helps in maintaining the equipment’s longevity and optimal performance.

Understanding the Tool Assembly Layout

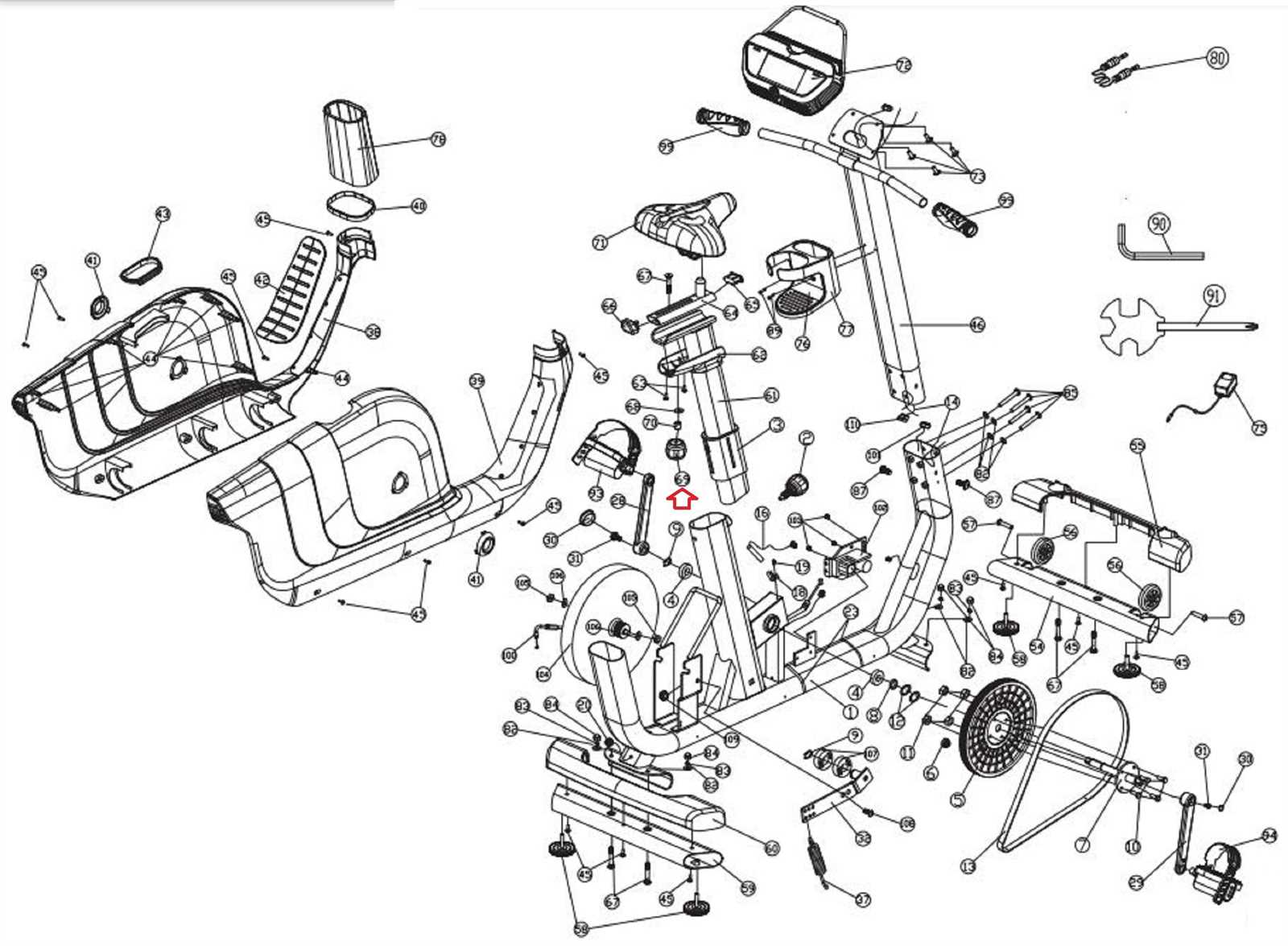

In any mechanical device, the proper organization of its components plays a significant role in both functionality and ease of maintenance. Knowing how each individual element is positioned within the system helps in troubleshooting and replacing worn or damaged components. A well-organized layout allows for a clearer understanding of how each piece interacts with others, ensuring that every part serves its intended purpose and operates efficiently.

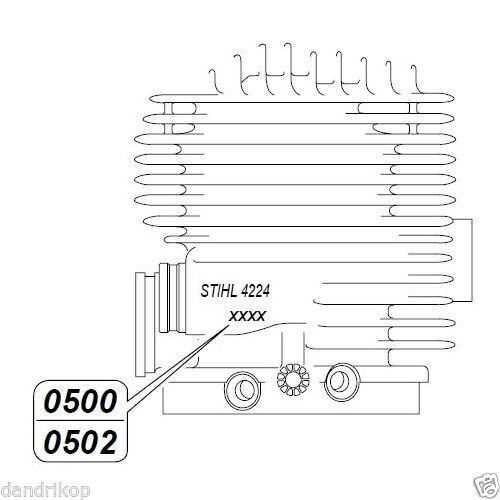

Component identification is key to quick repairs. A visual reference guide offers insight into the exact location of each part, allowing users to pinpoint issues more effectively. By familiarizing oneself with the layout, one can easily identify which parts need attention and how to proceed with repairs or replacements without confusion or unnecessary disassembly.

Efficient operation depends on the accuracy of assembly. Each element must be carefully positioned to avoid potential malfunctions. Understanding the placement and relationship between various components not only streamlines repair processes but also extends the lifespan of the machine by ensuring that all parts are properly maintained and functioning in harmony.

Identifying Key Components in the Diagram

Understanding the essential elements of a machine is vital for efficient operation and maintenance. A clear visualization of the core components allows for quick identification when issues arise or replacements are needed. Recognizing the function and position of each part helps in determining which areas require attention and ensures that repairs can be carried out with precision.

Critical Elements for Efficient Repair

Some components play a more significant role than others in maintaining the overall performance of the equipment. These key parts are often the focus when performing diagnostics or repairs, as they directly influence the tool’s functionality. By learning to identify these parts quickly, you can troubleshoot effectively and avoid unnecessary disassembly.

Visualizing Component Interactions

The relationship between various components is also important. Understanding how parts interact with each other and their contribution to the system’s operation ensures that any changes or fixes made are in the right place. A comprehensive guide makes this process easier by clearly showing how everything fits together, helping to avoid mistakes and reduce downtime.

How to Use the Assembly Layout for Repairs

When performing repairs on complex machinery, a visual reference of the tool’s structure can be an invaluable resource. Understanding how to navigate this reference effectively allows for a more precise approach to fixing or replacing damaged components. By identifying the specific part that requires attention, you can reduce the time spent searching for the issue and ensure a smoother repair process.

Start by locating the part that you believe is malfunctioning. Cross-reference it with the visual guide to ensure you have the correct identification. This helps avoid mistakes and unnecessary disassembly of non-problematic parts. Once the problematic component is identified, use the guide to determine the best method for removal or replacement, making the task more straightforward.

Additionally, a clear guide will help you understand how each component interacts within the overall structure. This understanding ensures that new parts are properly installed and aligned, preventing potential future issues and enhancing the efficiency of the repaired system.