Maintaining your lawn mower in top condition requires a thorough understanding of its internal and external components. By familiarizing yourself with the layout and function of each part, you can ensure smooth operation and extend the life of your machine. Whether you’re a seasoned mechanic or a first-time owner, knowing how to identify and replace damaged components is key to proper upkeep.

Effective maintenance involves more than just regular cleaning; it’s essential to recognize when parts wear out and need replacement. With the right information, you can diagnose issues quickly and avoid costly repairs down the line. Knowing how to read and use a visual guide to parts can make troubleshooting much easier.

When you are equipped with detailed references and step-by-step guidance, performing basic repairs yourself becomes a simple task. This approach not only saves time and money but also gives you a deeper appreciation of how your equipment functions. In this guide, we will walk you through the most important aspects of identifying components, understanding their roles, and carrying out maintenance efficiently.

Understanding Lawn Mower Components

Every lawn mower is built with a variety of key elements, each contributing to its overall performance. These components work together to ensure the machine operates smoothly, from the engine to the cutting mechanism. Recognizing the function of each part allows you to make informed decisions when it comes to maintenance or repair.

Key Elements of a Lawn Mower

The main elements that power a lawn mower include the engine, transmission, wheels, and cutting blades. Each part is essential for efficient operation, and understanding their role can help with troubleshooting when problems arise. For instance, the engine provides the necessary power, while the transmission ensures the mower moves forward and backward at the desired speed. The blades are crucial for a clean, even cut, and the wheels affect maneuverability on various terrains.

Importance of Regular Inspection

Regular inspection of each component is vital to avoid unexpected failures during use. Over time, parts may wear down due to constant movement or exposure to outdoor elements. For example, belts can stretch or break, and engine filters may become clogged. By checking these components periodically, you can replace or repair them before they affect the mower’s performance. A proactive approach helps maintain optimal functionality and reduces the need for expensive repairs.

Maintaining a strong understanding of your equipment’s internal structure ensures that you’re prepared for any situation. Whether performing minor adjustments or replacing worn parts, being familiar with your mower’s components gives you greater control over its upkeep.

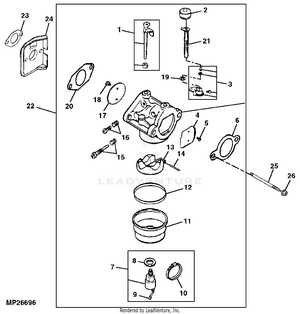

How to Use the Parts Diagram Effectively

Visual references are invaluable tools when working with machinery. They offer a clear, easy-to-understand overview of the components and their positions, helping you locate and identify each part quickly. Knowing how to interpret these references can make maintenance and repairs much simpler, especially when replacing or fixing specific elements.

Steps for Efficient Use

To make the most of these visual guides, follow these simple steps:

- Familiarize Yourself with the Layout: Before starting any repairs, take time to understand the overall layout. Identify major sections such as the engine, transmission, and cutting components.

- Locate the Part in Question: When an issue arises, look up the specific part you need. These guides typically group similar parts together, making it easy to find the one you’re after.

- Verify the Part Number: Always double-check the part number against the guide to ensure compatibility. This reduces the risk of ordering the wrong component.

- Understand Part Interaction: Some components rely on others to function properly. Understanding how they interact can help prevent further damage during repairs.

Common Mistakes to Avoid

While using a visual reference can simplify the process, certain mistakes can hinder your progress. Avoid the following:

- Not double-checking the part number before purchasing.

- Skipping the step of understanding part connections and functionality.

- Attempting repairs without the proper tools or knowledge of the part’s placement.

By following these steps, you ensure a smoother repair process and reduce the chances of mistakes. Properly using these references allows for quicker, more effective fixes, keeping your equipment in top working condition.

Common Repairs for Lawn Mowers

Regular maintenance and timely repairs are essential to keep your equipment running smoothly. Over time, various components may wear out or malfunction, affecting the overall performance. Identifying common issues early on and knowing how to fix them can prevent further damage and ensure optimal functionality.

Engine and Power System Repairs

The engine is the heart of any lawn mower, and it’s crucial to keep it in top condition. One of the most common issues is a malfunctioning starter or dead battery, which can prevent the machine from starting. Replacing the battery or cleaning the spark plugs often resolves these problems. Additionally, fuel system problems such as clogged filters or damaged fuel lines can cause poor performance and engine stalling. Regularly cleaning and replacing these components helps maintain a smooth-running engine.

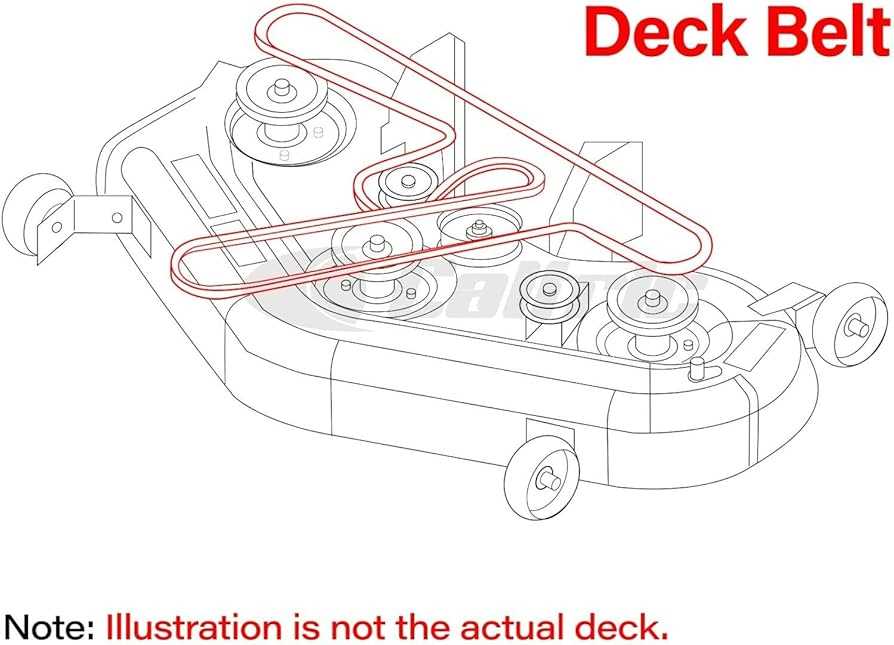

Transmission and Cutting Blade Issues

The transmission system is another area that frequently requires attention. Problems such as slipping gears or difficulty shifting can be due to worn-out belts or low fluid levels. Checking and replacing the drive belt or topping up transmission fluid can restore proper operation. Additionally, cutting blades often need sharpening or replacement after prolonged use, especially if the mower is used on tough grass or debris. Ensuring the blades are sharp and properly aligned is essential for achieving a clean, even cut.

Addressing these issues promptly helps maintain the mower’s efficiency, extending its lifespan and reducing the risk of costly repairs down the road. Regular inspections and timely replacements of worn parts are key to keeping your equipment in peak condition.