When it comes to maintaining your lawn equipment, understanding its individual components is crucial. Knowing how each part functions and connects with others ensures that repairs and maintenance are carried out effectively. Whether you’re a seasoned technician or a DIY enthusiast, having a clear understanding of the system is essential for smooth operation.

To help with repairs and replacements, it’s important to consult the appropriate resources that provide detailed visual guides. These guides allow you to easily identify the various elements within the machine, ensuring you’re equipped with the knowledge to troubleshoot and fix any issues that arise.

Common issues, such as engine malfunctions, blade wear, and transmission problems, often require part replacements. Having a visual reference helps you make accurate decisions, minimizing downtime and ensuring the longevity of your equipment.

L120 John Deere Parts Overview

Understanding the core elements of your lawn equipment is fundamental to its maintenance and performance. Each machine consists of several interconnected components that work together to ensure smooth operation. Familiarizing yourself with these essential parts not only helps in routine upkeep but also aids in identifying and fixing problems quickly.

The most critical elements include the engine, transmission, blades, and fuel system. Each plays a pivotal role in the overall function of the mower, and being aware of their specifications and how they interact is key to efficient repairs and replacements.

Engine and Transmission

The engine is the powerhouse of the mower, responsible for generating the necessary force to drive the machine. The transmission, on the other hand, transfers this power to the wheels, enabling movement. Regular inspection of these components ensures optimal functionality and prevents overheating or power loss issues.

Blades and Fuel System

Blades are essential for cutting grass efficiently, and over time, they may become dull or damaged. The fuel system, which includes the tank, filter, and pump, is vital for proper engine performance. Ensuring these elements are in good condition helps maintain both cutting efficiency and overall engine health.

Identifying Key Components for Repair

Effective repairs begin with knowing which components are essential for the proper functioning of your equipment. Recognizing the most critical elements that require attention can help streamline the maintenance process. Understanding how these parts work together ensures that replacements and fixes are accurate and timely.

The most commonly serviced components are the engine, cutting mechanism, and the power transmission system. By regularly inspecting these parts, you can identify wear and tear or potential failures before they affect the overall performance of the machine.

Engine and Power Systems

The engine is responsible for the overall power generation, and the transmission system is crucial for transferring this power efficiently. A malfunction in either of these systems can lead to a decrease in performance. Regular checks on fuel filters, belts, and engine condition can help prevent these issues from escalating.

Cutting Mechanism and Blades

The cutting system, including the blades, is directly responsible for the efficiency of the lawn mower. Dull or damaged blades can result in uneven cuts or unnecessary strain on the engine. Inspecting the blades for signs of wear and replacing them when needed ensures a clean, efficient cut every time.

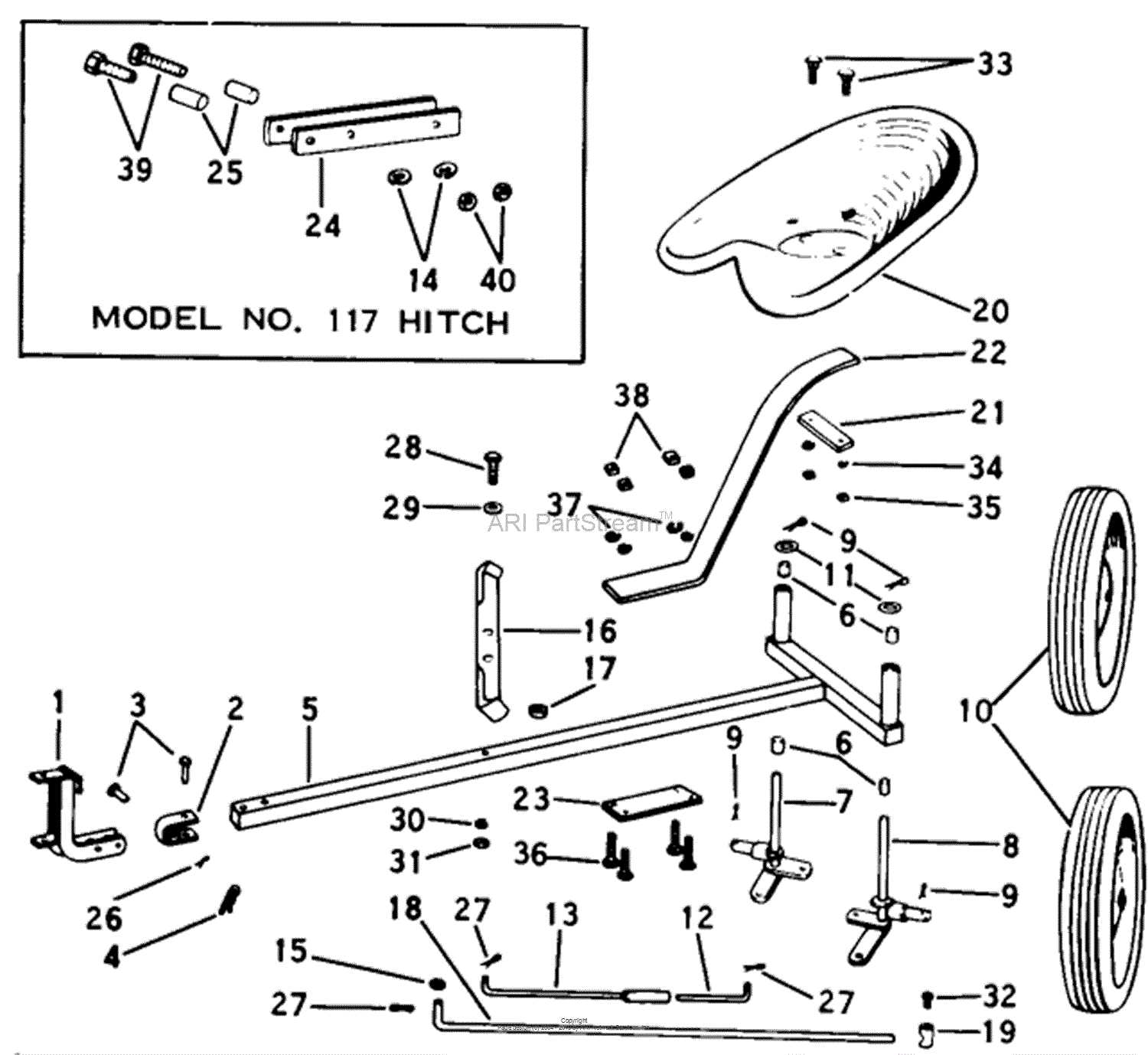

How to Read L120 Parts Diagrams

Understanding how to interpret visual guides is an essential skill when it comes to maintaining or repairing your lawn equipment. These illustrations offer a clear representation of the machine’s components and their layout, allowing you to identify parts and understand their connections. By learning how to read these guides, you can pinpoint specific parts that need attention or replacement.

These guides typically display the equipment in a clear, exploded-view format. This style helps you visualize the relationship between components, making it easier to find and replace faulty elements. The key is to understand the markings, labels, and numbering systems used to identify each component.

Understanding the Layout and Symbols

Most visual guides feature a layout where each part is numbered or labeled, often with a reference key beside it. Symbols are used to indicate specific instructions, such as arrows showing movement or labels pointing to the location of critical elements like bolts or screws. Familiarizing yourself with these symbols will help you navigate the diagrams with ease.

Following the Assembly Sequence

The guide will also present an assembly sequence to show how the parts fit together. By following this, you can understand the order in which components should be disassembled or reassembled. This step is crucial for ensuring that repairs are completed correctly without damaging any parts during the process.

Step-by-Step Guide to Diagrams

Using visual guides effectively requires understanding how to break down the information presented in each step. By following a structured approach, you can identify components, troubleshoot issues, and complete repairs with accuracy. This step-by-step method ensures you don’t miss crucial details that could affect the function of your equipment.

Each diagram is designed to guide you through the assembly or disassembly process. By following the order of steps, you can ensure that parts are handled properly and replaced when necessary. This organized process is key to making repairs efficiently without damaging other components.

Step 1: Identify the Components

The first step is to locate the key components within the visual guide. Pay close attention to the labels and numbers assigned to each part. This will help you recognize which pieces need inspection or replacement.

Step 2: Follow the Assembly Instructions

Once the parts are identified, follow the sequence in which they should be assembled or disassembled. These instructions are critical for ensuring that no components are overlooked or misplaced during the process.

| Step | Action | Components to Check |

|---|---|---|

| 1 | Identify components | Engine, transmission, cutting blades |

| 2 | Disassemble as per sequence | Belts, bolts, fuel system |

| 3 | Reassemble following guide | All previously identified parts |

Common Issues and Parts Replacement

Over time, machinery may experience wear and tear that affects its performance. Identifying common issues early can help prevent further damage and ensure that your equipment continues to function at its best. Replacing worn-out components at the right time is essential to maintain optimal efficiency.

Several components are prone to issues such as damage, wear, or clogging, making them prime candidates for replacement. Regular inspection and timely action can significantly reduce downtime and improve the longevity of your machine.

Common Problems

- Engine Failure: Overheating or improper maintenance can lead to engine malfunctions.

- Clogged Fuel System: Dirt or debris buildup can obstruct fuel flow, causing performance issues.

- Dull or Damaged Blades: Blades may become dull or chipped, leading to uneven cuts and added strain on the engine.

- Transmission Issues: A faulty transmission can cause problems with speed control and movement.

Replacement Recommendations

- Engine: Check the spark plugs, air filters, and oil regularly. Replace damaged parts as needed.

- Fuel System: Replace the fuel filter and clean the fuel lines to ensure proper fuel flow.

- Blades: Inspect for wear or damage and replace blades that no longer cut effectively.

- Transmission: Inspect belts, pulleys, and cables for wear, and replace them if they show signs of damage or wear.