Maintaining the functionality of an engine requires understanding the internal components and how they interact. When repairs or replacements are needed, a clear overview of each part is essential for efficient troubleshooting. This guide will help you navigate through the essential elements of your engine and provide insights on keeping it running smoothly.

By examining a detailed breakdown of your engine’s structure, you can quickly identify potential issues and locate the necessary replacements. Whether you are performing routine maintenance or dealing with unexpected malfunctions, having a clear understanding of the system will save you time and effort. This information will also help in sourcing the correct replacements to avoid costly mistakes.

Familiarizing yourself with the layout and functions of the various components will lead to more informed decisions when repairing or upgrading the system. With the right knowledge, you can ensure that your engine continues to operate at peak performance, minimizing downtime and maximizing longevity.

Understanding Engine Components

Every engine consists of various key elements that work in unison to deliver optimal performance. These components, ranging from fuel systems to ignition systems, each play a vital role in maintaining the engine’s functionality. A comprehensive understanding of how these pieces fit together is essential for proper maintenance and troubleshooting.

At the core of the engine are the primary elements, such as the crankshaft, pistons, and camshaft, which are responsible for converting energy into motion. These internal parts rely on supporting systems, including cooling, lubrication, and electrical circuits, to ensure smooth operation. Each piece is designed with precision to handle specific functions that contribute to the engine’s overall efficiency.

Identifying and understanding the different elements can help users quickly pinpoint issues when they arise. Whether you’re conducting routine maintenance or performing more complex repairs, recognizing each component’s role will make the process more straightforward and effective.

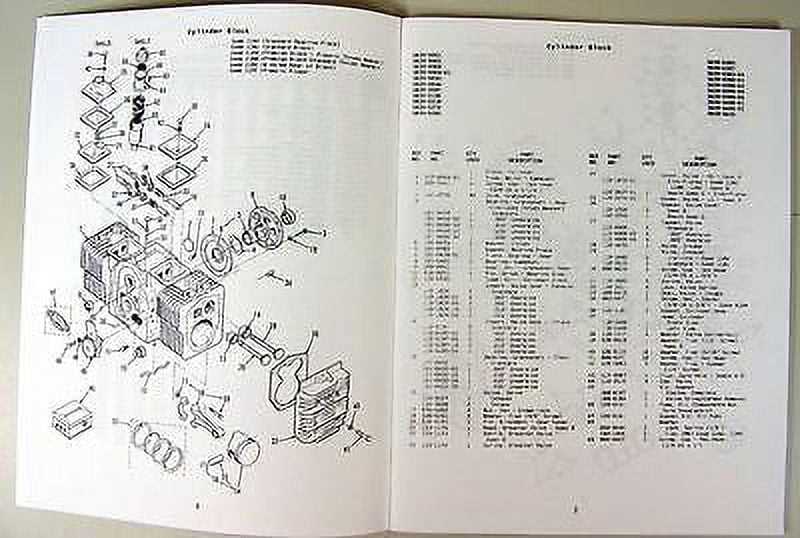

How to Read Engine Schematic

Interpreting an engine schematic requires understanding the layout of its components and how they are connected. These visual representations provide a clear map of the internal systems, showing how each element interacts with the others. Properly reading this schematic will help you identify key components and their functions, making maintenance and repair much easier.

The first step in reading the schematic is to familiarize yourself with the symbols used to represent various parts. These symbols indicate different systems such as the fuel, electrical, and cooling systems, and each part is labeled for easy identification. Pay attention to the lines connecting the symbols, as they show how the systems are interlinked and where the flow of energy or fluids occurs.

Once you have a basic understanding of the schematic symbols and connections, you can start analyzing the specific sections relevant to your issue. By following the flow from one part to another, you can pinpoint where problems may lie and determine which components need attention or replacement.

Common Issues and Component Replacements

Engines, like any complex machinery, can experience various issues over time. These problems often arise due to wear and tear, improper maintenance, or manufacturing defects. Recognizing common issues early on can help prevent further damage and ensure the engine operates efficiently for a longer period.

Some frequent concerns include fuel system blockages, faulty ignition components, or worn-out belts. In many cases, these issues can be traced to specific components that need replacement. For example, a clogged fuel filter may restrict fuel flow, leading to poor engine performance. Similarly, a malfunctioning spark plug can cause misfires or difficulty starting the engine. Regularly inspecting these critical parts will help in identifying the root cause of problems and determine which parts require attention.

Replacing worn or damaged components is essential to maintaining optimal engine performance. Once the problematic part is identified, sourcing the correct replacement ensures that the system continues to function as intended. With the right tools and knowledge, many of these repairs can be done efficiently, reducing downtime and improving the engine’s reliability.