Understanding the inner workings of your agricultural equipment is essential for proper maintenance and repair. When issues arise, having a clear reference can significantly reduce downtime and ensure efficient operations. Knowing where each component fits and how they interact allows for better decision-making when it comes to servicing your machine.

With the help of detailed visual references, even complex tasks can be simplified. These resources provide step-by-step guidance, highlighting the various elements that make up the system, enabling you to quickly identify and address any potential problems. Accurate identification of each part ensures that the right repairs are made promptly, preventing further damage.

Whether you are a seasoned operator or new to equipment maintenance, using these comprehensive references is a smart approach. Proper upkeep not only extends the life of your machine but also enhances its performance, making it an invaluable tool in your daily operations.

Understanding Tractor Components

Every piece of machinery consists of various crucial elements that work together to ensure optimal performance. A deep understanding of these components is essential for diagnosing issues and making necessary repairs. Recognizing the function and location of each part helps operators quickly identify problems and address them effectively, reducing downtime and increasing efficiency in the field.

The Importance of Component Awareness

Familiarity with the machine’s structure and how each section contributes to the overall functionality can make troubleshooting easier. From the engine to the transmission, each system has its role in maintaining smooth operation. When issues arise, pinpointing the specific malfunctioning component allows for more precise repairs and less disruption to your daily tasks.

How to Identify and Manage Components

When managing repairs, having a clear reference to each item and its function is key. Visual references and manuals provide operators with detailed descriptions, showing how each component interacts within the system. This approach enables faster identification of any damaged or worn parts, helping you determine whether they can be repaired or need replacement.

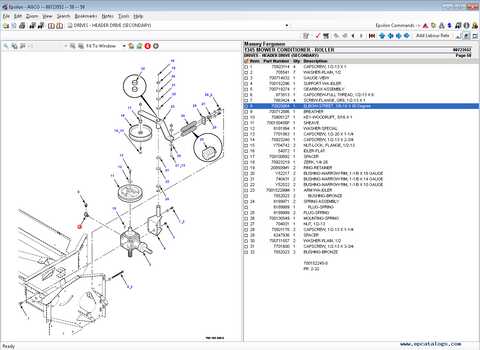

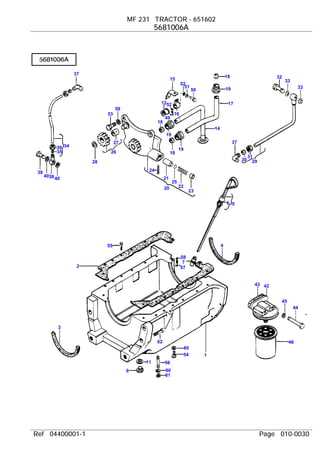

How to Use the Parts Diagram Effectively

To ensure smooth repairs and maintenance, having a clear visual reference is invaluable. These references break down the structure of a machine, allowing operators to see exactly where each component fits and how they interact. Knowing how to interpret these visual tools can save time, reduce errors, and improve overall repair efficiency.

Step-by-Step Analysis of the Visual Reference

Begin by familiarizing yourself with the layout of the schematic. Each section is typically divided into logical groupings, showing related components together. Start by identifying the main systems, such as the engine or transmission, and then move to the smaller, connected elements. By following this flow, you’ll better understand the machine’s structure and the relationships between its various parts.

Using the Diagram for Troubleshooting

When an issue arises, use the reference to locate the specific system affected. By knowing the general layout, you can quickly narrow down where problems are most likely occurring. This focused approach can help you quickly spot broken, worn, or malfunctioning components, making the repair process much more efficient and effective.

Common Repairs for Agricultural Machinery

Maintaining agricultural equipment involves addressing a variety of issues that may arise during operation. From engine malfunctions to transmission problems, regular upkeep ensures that the machine remains reliable and functional. Identifying common failures and understanding how to fix them is key to preventing costly repairs and reducing downtime in the field.

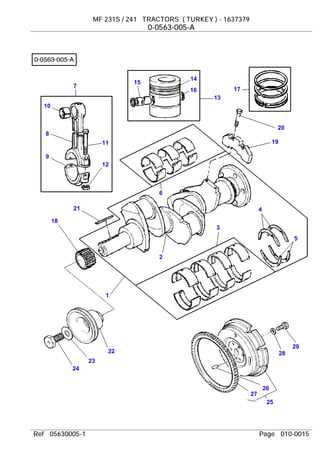

Engine and Fuel System Repairs

The engine is the heart of any machine, and issues with fuel delivery or ignition can significantly impact performance. Common problems include clogged fuel filters, faulty injectors, or issues with the starter motor. Regular inspection of the fuel system and ensuring clean fuel lines can help prevent such problems from occurring. If engine failure happens, a detailed inspection of the components can help pinpoint the exact cause and guide repairs efficiently.

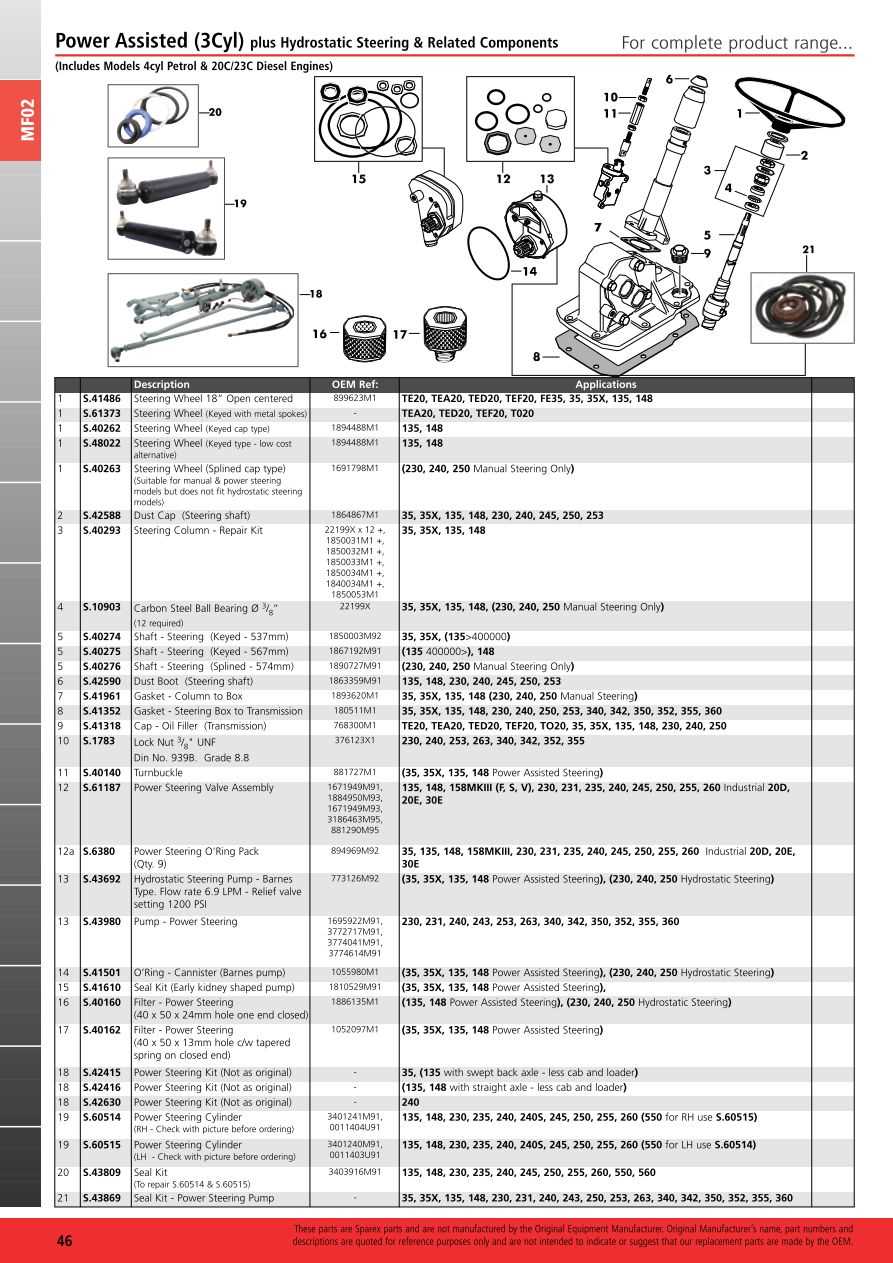

Transmission and Hydraulic System Fixes

Transmission and hydraulic failures can also lead to significant operational disruptions. Issues like low fluid levels, leaks, or worn seals can affect the performance of the transmission and hydraulic systems. Regular checks of fluid levels and seals, along with timely replacement of damaged components, can prevent costly repairs and keep the machinery running smoothly.