Efficient maintenance of heavy machinery requires a clear understanding of its internal structure and functional elements. Having access to a detailed visual guide can make the repair and upkeep process much simpler, allowing owners and mechanics to quickly identify each crucial component.

Knowing the layout of key elements in an agricultural machine is essential for anyone who operates or services such equipment. By familiarizing yourself with the positioning and function of these elements, you can minimize downtime and extend the machine’s lifespan.

Repairing specific parts requires accuracy and attention to detail, and with a proper reference, even complex tasks become more manageable. Whether you are a professional technician or a DIY enthusiast, understanding these visual aids is an indispensable tool for successful maintenance.

Understanding Agricultural Machine Components

For effective operation and maintenance of heavy farming equipment, it’s crucial to have a deep understanding of its individual elements. Each component plays a vital role in ensuring that the machine runs smoothly, and recognizing their specific functions is key to troubleshooting and repairs.

From the engine to the transmission system, every aspect of the machine is designed for efficiency. Identifying these elements and their interconnections helps users quickly address any mechanical issues that may arise during operation.

By familiarizing yourself with the key systems, such as the hydraulic setup and the electrical components, you can perform precise maintenance and avoid costly breakdowns. Accurate knowledge also allows for better decision-making when it comes to part replacements or upgrades.

How to Use a Parts Diagram Effectively

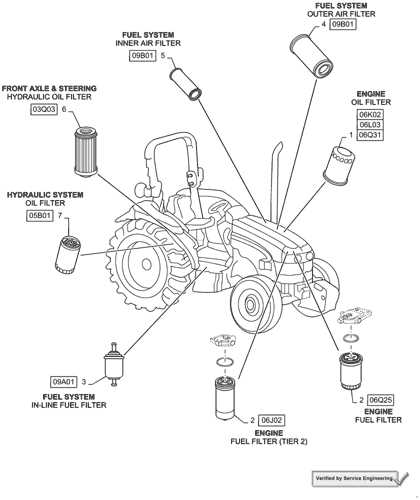

When repairing or servicing complex machinery, having a visual reference can significantly improve the accuracy and efficiency of the process. A well-organized guide helps identify each part and its corresponding function within the system, making it easier to locate issues and find the right solutions.

Start by reviewing the entire layout to get familiar with the overall structure before focusing on specific components. This gives a clearer understanding of how the different elements interact and depend on each other, ensuring a comprehensive approach to repairs.

Pay attention to labels and numbers that often accompany these visual guides, as they will help you cross-reference with manuals or online resources to find the exact specifications for replacement or maintenance. Knowing how to read these guides efficiently will save you time and minimize the risk of errors during repairs.

Common Replacement Components for Agricultural Machines

Heavy farming equipment is subject to wear and tear, and certain elements often require replacement over time. These components are crucial to the machine’s performance and should be replaced promptly to avoid operational disruptions.

Engines, hydraulic systems, and transmissions are some of the most commonly replaced parts due to their high usage and complex functions. Regular inspection of these areas helps prevent unexpected breakdowns and ensures smooth operation during intensive work.

Filters, belts, and seals are also frequently replaced as part of routine maintenance. While these parts may seem minor, their proper function is essential for the overall efficiency and longevity of the machine.