When working with a kitchen appliance designed for grinding or mincing, knowing its key elements is essential for both effective operation and maintenance. Each piece within this tool plays a crucial role in its overall function. Whether you are using the device for preparing fresh ingredients or handling more heavy-duty tasks, the proper understanding of its structure can improve your experience.

Identifying the specific roles of each component helps ensure smooth usage and efficiency. A thorough knowledge of the system allows you to troubleshoot potential issues, enhance the lifespan of your equipment, and even improve the quality of your output. Regular care and attention to each part can prevent malfunctions and ensure consistent performance over time.

By breaking down the mechanism into individual sections, you gain insight into how everything works together, from the initial input to the final product. With a detailed overview, anyone can gain confidence in using and maintaining the machine, leading to better results and less downtime.

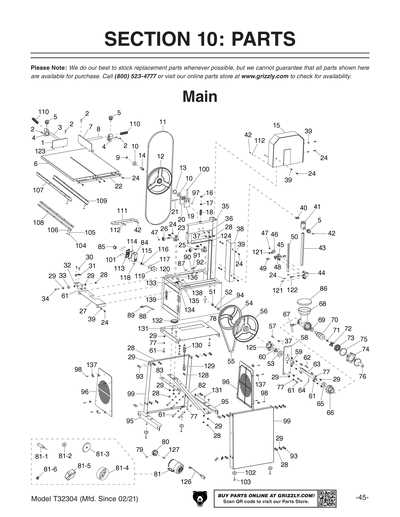

Key Components of a Food Processing Machine

Every appliance designed for mincing and chopping consists of several critical components that work together to ensure smooth operation. These elements, when properly maintained, guarantee that the system functions at its peak efficiency, enabling it to handle various tasks effectively. Understanding each key piece helps users make informed decisions during setup, operation, and upkeep.

Feeding and Grinding Mechanism

The first stage of processing involves feeding and preparing the ingredients for grinding. The hopper is where the input is placed, while the auger ensures a steady flow towards the grinding area. These components work in harmony to direct the materials into the next stage with minimal effort.

Cutting and Output Assembly

Once the materials are directed into the machine, the cutting blades and plates come into play. The blades slice through the input, while the plates determine the final texture of the output. These parts are essential for shaping the product and ensuring consistency across different uses.

Identifying the Function of Each Part

Each element of a food processing tool plays a distinct role in its overall operation. Understanding the function of every component helps users optimize the machine’s performance and troubleshoot any potential issues. By recognizing the purpose of each section, the user can ensure smooth, efficient, and safe use of the device.

Feeding and Directing Mechanisms

The hopper serves as the initial entry point for ingredients, while the auger transports them towards the cutting system. Together, they ensure that materials flow steadily into the device, preventing blockages and ensuring consistent processing.

Cutting and Shaping Tools

The blades and plates work in tandem to slice and shape the input. The blades provide the initial cutting action, while the plates control the output’s texture by determining the size of the final pieces. These components are essential for achieving the desired result, whether it’s for fine or coarse processing.

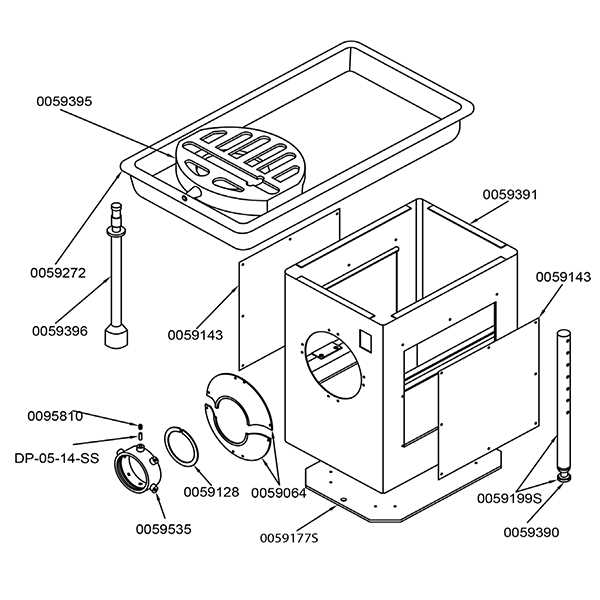

How to Assemble a Food Processing Tool

Assembling a kitchen appliance designed for chopping or mincing is a straightforward process if the steps are followed carefully. Proper assembly ensures that all components fit together securely, allowing the machine to operate efficiently. Familiarity with the parts and their functions will make the process smoother and reduce the chances of errors.

Step-by-Step Assembly Process

- Prepare the Base – Start by placing the base unit on a stable surface. This part will serve as the foundation for the rest of the components.

- Attach the Auger – Insert the auger into the base unit, ensuring it fits into the designated slot. This piece will direct the ingredients towards the cutting mechanism.

- Install the Cutting Blades – Secure the cutting blades onto the auger assembly. Ensure they are tightly fastened to avoid any slippage during operation.

- Place the Plates – Depending on the desired texture of the output, select the appropriate plate and attach it to the assembly. Make sure it is aligned correctly for smooth processing.

- Secure the Hopper – Attach the hopper to the top of the device, making sure it locks into place firmly. This will be the feeding point for ingredients.

Final Checks Before Use

- Ensure all parts are tightly assembled to avoid any loose connections.

- Check that the auger is turning freely and not obstructed by any parts.

- Test the assembly without any ingredients to confirm everything moves as expected.

Step-by-Step Guide for Proper Setup

Setting up a kitchen device for mincing or chopping requires careful attention to detail to ensure everything functions correctly. A proper setup not only maximizes the performance of the tool but also guarantees safety during use. Following these steps will help you assemble the components efficiently and ensure the machine is ready for operation.

Preparation Before Assembly

Before beginning the assembly, make sure all components are clean and dry. It’s important to ensure that no debris or moisture is present to avoid any operational issues. Also, have a stable surface available for placing the appliance to prevent any accidents during setup.

Assembly and Configuration

| Step | Action | Notes |

|---|---|---|

| 1 | Place the base unit securely on a flat surface. | This will serve as the foundation for the setup. |

| 2 | Insert the auger into its designated slot. | Ensure it is aligned properly to avoid jamming during operation. |

| 3 | Attach the cutting blades firmly onto the auger. | Double-check to make sure they are securely fastened. |

| 4 | Install the output plate based on the desired texture. | Choose a plate with the correct hole size for your needs. |

| 5 | Affix the hopper on top of the assembly. | Make sure it locks into place and is secure. |

Maintaining and Cleaning Grinder Parts

Proper maintenance and regular cleaning are essential to ensure the longevity and efficiency of a kitchen device used for chopping and mincing. Keeping the components in top condition not only improves performance but also reduces the risk of contamination and mechanical issues. Regular upkeep is crucial for maintaining the hygiene and functionality of the tool.

Routine Maintenance Tips

Start by regularly inspecting the components for any signs of wear or damage. Pay close attention to the blades and plates, as they are subjected to the most wear. If you notice any dullness or unevenness, sharpening or replacing them may be necessary to maintain smooth operation.

Effective Cleaning Techniques

Cleaning the appliance after every use is vital to prevent buildup of food particles, which can lead to bacterial growth or clogging. Here are some essential steps to follow:

- Disassemble the components carefully and rinse them with warm water immediately after use.

- Use mild detergent and a soft brush to scrub any stubborn residue from the surfaces.

- Dry all parts thoroughly before reassembling to prevent rust or corrosion.

- Store the appliance in a dry, cool place to maintain its condition when not in use.

By consistently following these practices, you can extend the lifespan of your equipment and ensure it remains in optimal working condition for years to come.