Maintaining and repairing power tools is crucial for ensuring their longevity and optimal performance. Knowing the structure of your equipment and its components is the first step towards efficient maintenance. This knowledge allows for easier troubleshooting and faster repairs when something goes wrong.

In this guide, we’ll explore how understanding the individual parts of your tool can help you with repairs and upkeep. Having a clear view of the internal workings enables you to take action before issues escalate, saving time and money in the long run.

Familiarizing yourself with the key components of your tool is an essential part of effective maintenance. Being able to identify each piece makes repairs simpler and more straightforward. With the right information, even minor fixes can be done quickly without the need for professional assistance.

Kobalt KT1015 Table Saw Overview

This power tool is designed to provide precise cutting performance for various types of woodwork. Known for its durability and reliability, it is a popular choice for both DIY enthusiasts and professionals alike. Understanding the essential features and capabilities of this equipment is vital for ensuring its effective use in a variety of tasks.

The machine is equipped with multiple functionalities that allow users to perform different cutting operations with ease. Its robust construction ensures that it can withstand the demands of regular use, while the intuitive controls make it accessible for users of all experience levels. Regular maintenance and knowledge of its structure play an important role in preserving its efficiency over time.

Key features of this tool include adjustable settings that allow for accurate cuts in different materials. Additionally, the sturdy base and high-quality components ensure stability during operation, minimizing vibrations for smoother cuts. Familiarity with how these elements work together is essential for making the most out of the tool’s capabilities.

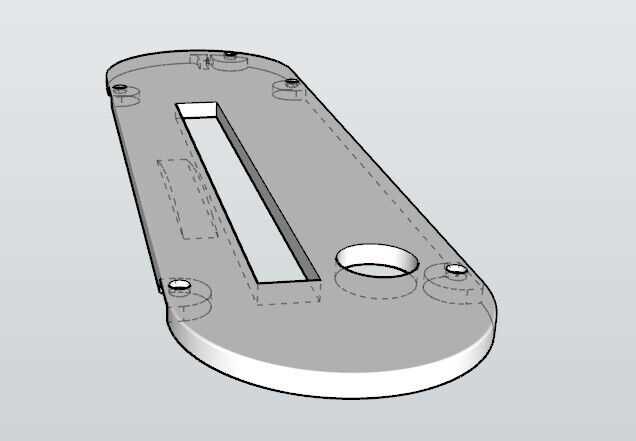

Identifying Key Components of KT1015

Understanding the main components of any power tool is crucial for proper maintenance and operation. Each part plays a specific role in the functionality of the machine, ensuring efficient performance. Identifying these essential elements will help you troubleshoot issues and make informed decisions during repairs or upgrades.

The key components of this tool include its motor, drive mechanism, and cutting mechanism, each contributing to its overall efficiency. The motor powers the tool, while the drive mechanism ensures consistent operation and the cutting mechanism performs the desired tasks with precision. Recognizing the individual parts and how they interact will help users perform necessary maintenance and identify potential issues before they become major problems.

Familiarity with these components allows users to better understand the tool’s operation and ensure that each part is functioning correctly. By knowing the location and role of each key element, users can easily spot when a component is worn or damaged, allowing for timely interventions and extending the tool’s lifespan.

How to Use the Parts Diagram Effectively

Utilizing a visual reference for tool components is essential for accurate repairs and maintenance. A detailed chart provides clear identification of each element, ensuring that users can locate specific pieces quickly and easily. Mastering the use of this reference tool is important for making repairs with precision and efficiency.

Understanding the Layout

When using a reference guide, it’s important to familiarize yourself with the layout. Each component is often labeled with specific identifiers, allowing you to match them with their corresponding names or part numbers. This helps to avoid confusion and ensures that every piece is correctly identified during maintenance or replacement procedures.

Steps for Effective Use

Begin by reviewing the entire guide to get a sense of the different components and their arrangement. Once you are familiar with the layout, start by locating the part that needs attention, then cross-reference it with the guide to ensure you are working with the right element. This process minimizes errors and speeds up repairs.