Having a clear understanding of your tool’s individual elements is crucial for efficient maintenance and repair. Knowing where each component fits into the larger mechanism allows for better care and faster troubleshooting. By familiarizing yourself with the specific parts, you can avoid common mistakes and ensure smooth operation for years to come.

Properly identifying and replacing worn-out components is essential for keeping your equipment running at its best. Whether you are fixing a broken piece or simply conducting routine upkeep, understanding how everything works together is key. This knowledge empowers you to take on repairs with confidence and accuracy, saving time and effort.

For those seeking detailed guidance on managing the system of internal parts, learning the layout of each section helps in making informed decisions. A thorough breakdown allows for efficient problem-solving, ensuring optimal performance with minimal downtime. With careful attention to the most critical aspects, you’ll be prepared for any necessary maintenance tasks.

Understanding the MS660 Parts Layout

To maintain optimal performance of your tool, it’s essential to grasp the structure of its internal system. By familiarizing yourself with the individual components and their placement, you gain insight into how they function together to power the machine. This knowledge helps identify issues, simplify repairs, and prolong the lifespan of the equipment.

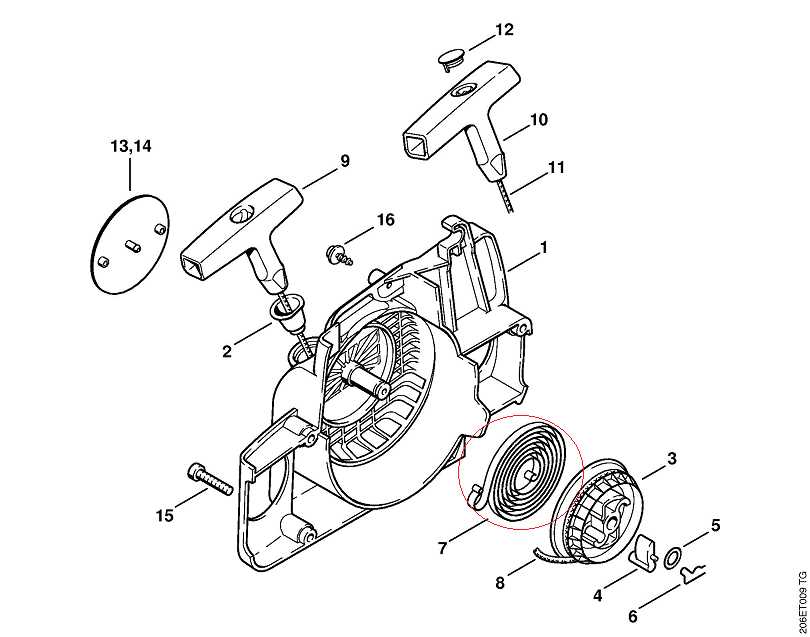

Key Components and Their Functions

The internal system of the machine consists of multiple elements, each serving a specific purpose. From the engine to the ignition system, every part plays a vital role in ensuring smooth operation. Understanding how each piece interacts with others enables you to spot potential problems early and take the right steps for correction.

Effective Repair and Maintenance Tips

Once you’re familiar with the layout, you can effectively carry out maintenance tasks such as replacing worn-out elements, tightening loose connections, or cleaning internal parts. Regular checks and basic upkeep are crucial for preventing unnecessary wear and tear. By knowing the exact placement of each component, you can ensure that all elements are in good working order, minimizing downtime and enhancing performance.

How to Identify Key Components of MS660

Identifying the key elements of your equipment is essential for understanding its functionality and performing effective maintenance. By recognizing the different sections, you can diagnose problems more quickly, replace damaged components, and maintain overall performance. Knowing the role of each piece helps prevent unnecessary wear and ensures the tool continues to function optimally.

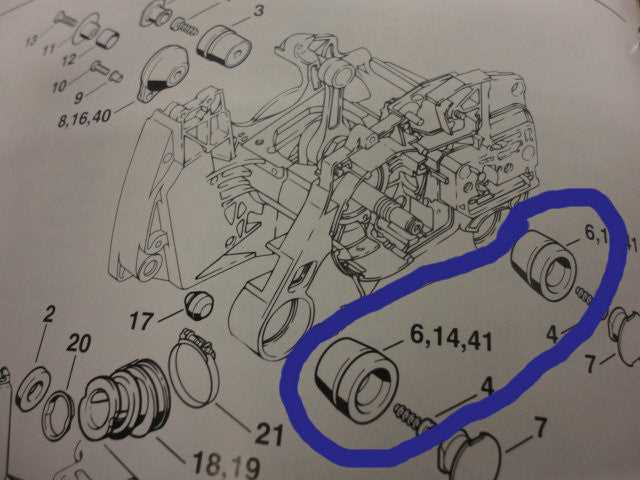

Recognizing the Engine and Ignition System

The engine is the heart of the machine, and understanding its structure is crucial. The ignition system, including the spark plug and coil, plays a pivotal role in starting and running the engine. Identifying these components allows you to troubleshoot starting issues, and regular inspection can prevent failures caused by wear and corrosion.

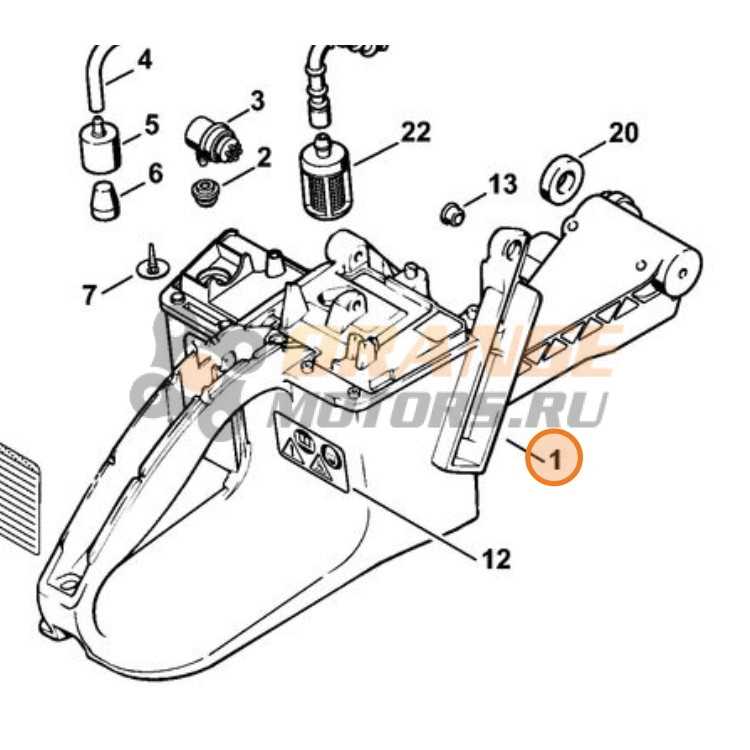

Understanding the Fuel and Air Flow Systems

Fuel delivery and air intake are equally important for the machine’s efficiency. The carburetor and air filter are vital in regulating fuel flow and ensuring the engine receives clean air. By identifying these systems, you can clean or replace filters and check for blockages to maintain proper airflow and fuel combustion, which directly impacts performance.

Steps for Effective MS660 Maintenance and Repairs

Regular maintenance and timely repairs are essential for keeping your equipment in peak condition. By following a structured approach to upkeep, you can avoid major malfunctions and extend the life of your tool. Proper care ensures smooth operation and reduces the risk of unexpected failures during use.

Start by performing routine checks on key systems, such as the engine, fuel lines, and air intake. Regular cleaning of the air filter, spark plug, and carburetor is necessary to ensure optimal performance. Inspecting and replacing worn components like the fuel filter or ignition coil can prevent disruptions during operation.

During maintenance, always use genuine replacements and follow the manufacturer’s guidelines for assembly and disassembly. This ensures proper fitting and reduces the risk of damaging components. After repairs, test the equipment in a controlled environment to confirm all systems are functioning correctly before regular use.