Having a clear understanding of the key components within your engine is crucial for maintaining optimal performance and ensuring safe operation. Whether you’re an experienced boater or a newcomer, knowing how each part functions will help you troubleshoot and prevent potential issues.

The system is made up of various interconnected elements, each playing a vital role in keeping the engine running smoothly. From the power generation unit to cooling mechanisms, every part is essential for effective operation. With the right knowledge, you’ll be able to identify problems early and tackle them before they lead to costly repairs.

Familiarizing yourself with these components can greatly enhance your ability to handle maintenance tasks, such as routine inspections or repairs. By understanding how these parts work together, you’ll gain the confidence to care for your engine properly and extend its lifespan.

Understanding Mercruiser 3.0 Engine Components

To ensure smooth and efficient operation of any boat engine, it is essential to understand how its various systems work together. The components of the engine are designed to perform specific tasks, such as generating power, maintaining cooling, and providing fuel. Familiarizing yourself with the different parts allows for better maintenance, troubleshooting, and overall care.

Key Components of the Engine

The engine consists of several critical units, including the ignition system, fuel delivery system, and cooling mechanisms. Each of these systems plays a role in ensuring the engine operates smoothly under varying conditions. Understanding their functions will help you recognize when maintenance is needed or if something goes wrong.

Maintaining Optimal Performance

Proper care and regular checks on the engine components can greatly increase its longevity and reliability. Key maintenance tasks, such as changing fluids, inspecting belts, and ensuring proper fuel flow, can prevent costly repairs. Knowing how to spot potential problems before they escalate is crucial for any boat owner.

How to Read the Parts Diagram

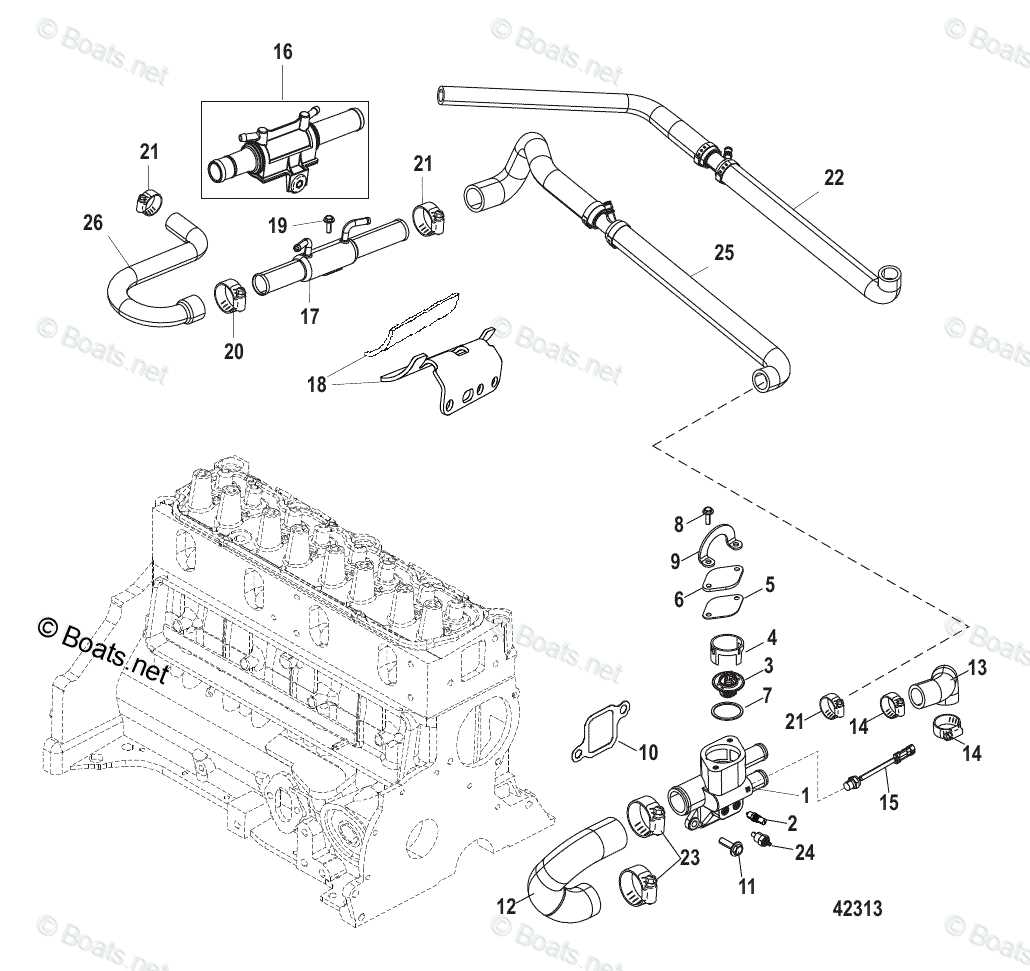

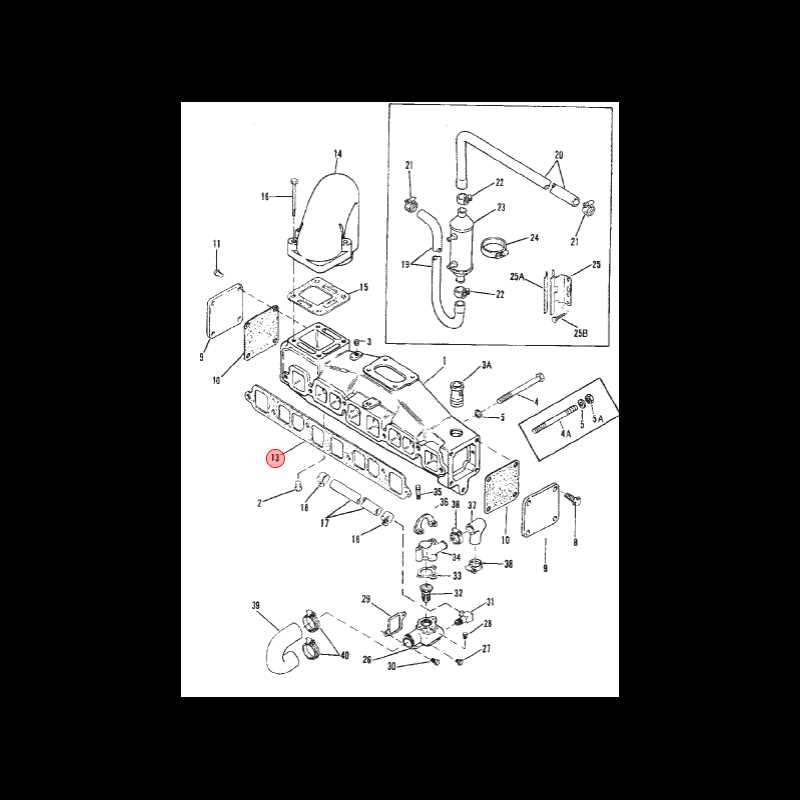

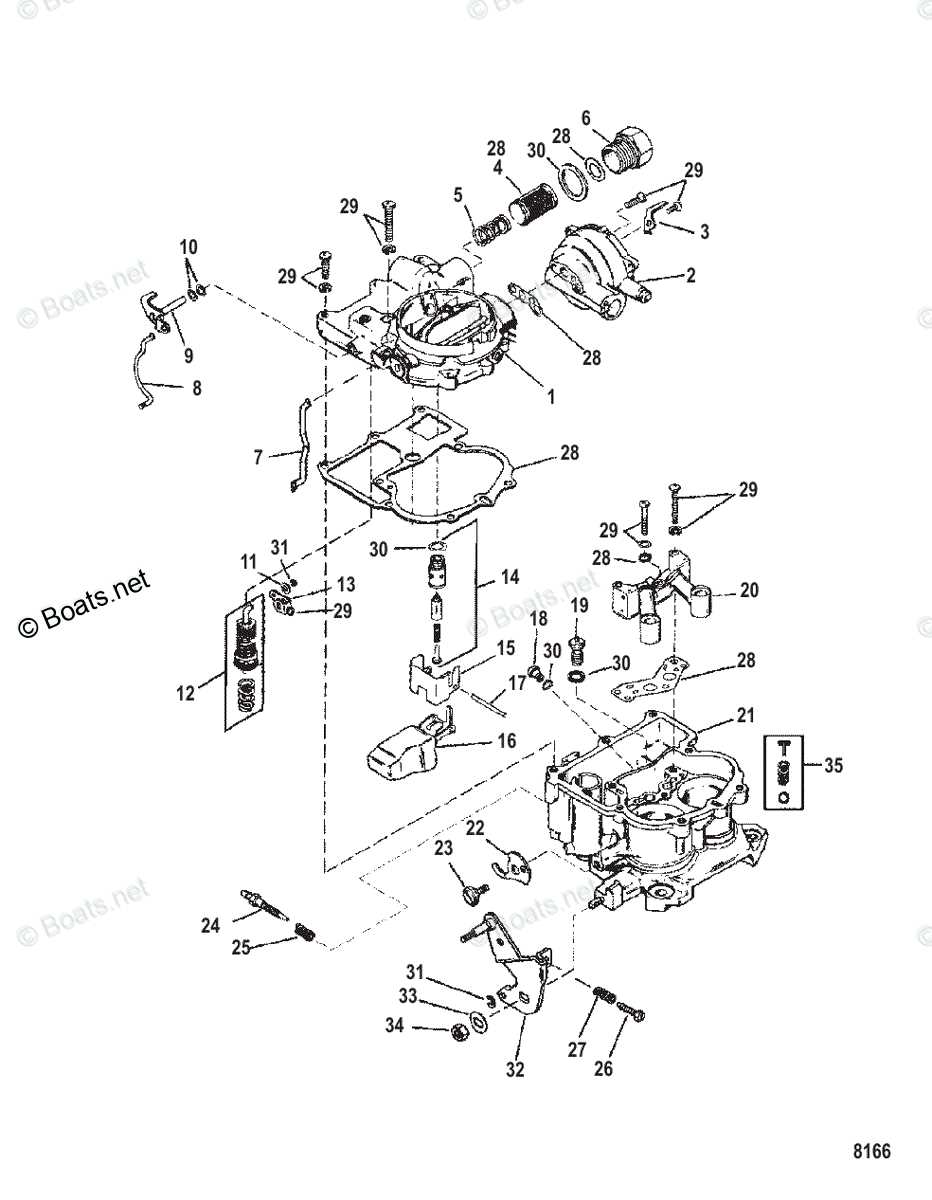

Interpreting a visual guide for engine components is essential for understanding the relationships between different parts and their functions. A clear, organized chart can help you easily identify each unit, its location, and how it connects with others. Learning how to navigate these diagrams will simplify maintenance and repair tasks.

Follow these steps to effectively read and use the diagram:

- Identify Key Labels: Look for labels that identify each component clearly. These often correspond to specific numbers or letters in the chart.

- Understand the Groupings: Parts are often organized into sections based on their function, such as fuel, ignition, and cooling systems.

- Locate Specific Components: Find the part you’re interested in, using the references provided, to understand its placement within the engine structure.

- Follow Connection Lines: Diagrams show how parts are interconnected. These lines represent pipes, wires, or mechanical links between units.

Once you are familiar with how to read the guide, you’ll be able to quickly pinpoint issues or plan your maintenance strategy with precision. Understanding the relationships between components ensures you handle any necessary adjustments or repairs effectively.

Common Issues and Parts Replacement Guide

Throughout the lifespan of an engine, certain components may experience wear and tear, leading to performance issues or malfunctions. Understanding the most common problems and knowing when to replace specific elements can help avoid costly repairs and keep the engine running smoothly. Proper maintenance and timely replacements ensure efficiency and extend the overall lifespan of the system.

Common Issues often arise from the following areas:

- Ignition system failure: A worn-out spark plug or faulty ignition coil can result in poor engine performance or difficulty starting.

- Fuel system clogging: Over time, fuel filters or injectors may become clogged, causing the engine to misfire or run inefficiently.

- Cooling system blockages: Overheating is a common issue when the cooling mechanism becomes obstructed by debris or if the water pump fails.

- Exhaust problems: Leaking or damaged exhaust components can cause increased emissions or engine strain.

When encountering these problems, it’s essential to replace worn components promptly. Regular inspections can help detect issues early, preventing larger system failures. Replacing faulty units at the right time can improve engine performance and prevent unnecessary downtime.

By following a well-structured replacement guide, you can ensure the ongoing reliability of your engine, allowing for smoother operation and a longer lifespan.