When it comes to maintaining and repairing your chainsaw, understanding its internal structure is essential. Knowing how each component fits together allows for better troubleshooting and more effective repairs. This guide aims to simplify the process by offering a detailed look at the essential parts of your saw and how they interact.

Proper maintenance relies on being able to identify individual elements and understand their role in the saw’s overall function. By familiarizing yourself with these components, you can save time and effort when addressing issues, ensuring a longer lifespan for your equipment.

In the following sections, we will explore the key pieces that make up your tool, offering practical advice on their functions and how to access them for replacement or repair. Whether you’re a professional or a hobbyist, having this knowledge at your fingertips will make your tasks more efficient and less intimidating.

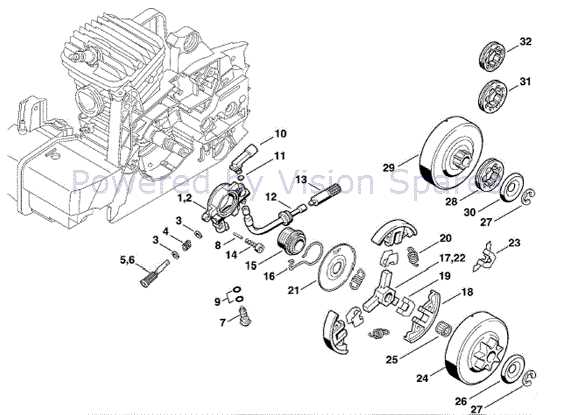

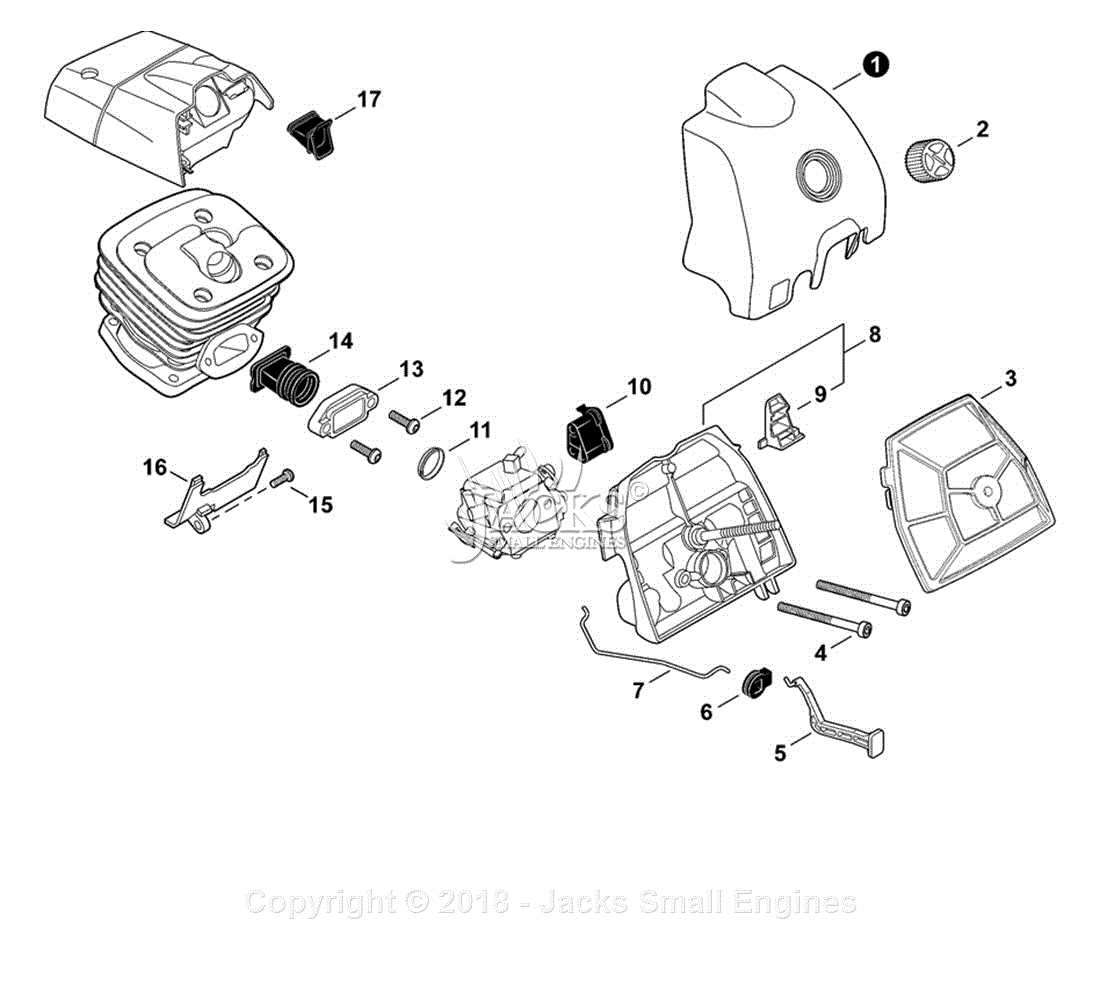

Understanding the Chainsaw Component Layout

Familiarizing yourself with the visual representation of your chainsaw’s internal structure is key to effective maintenance. A clear layout helps you identify each part’s role, how they interconnect, and where potential issues may arise. These visual guides serve as an essential tool for anyone looking to perform repairs or regular maintenance, providing a step-by-step reference for component assembly and disassembly.

How to Read a Component Map

Understanding a visual map of your chainsaw’s components begins with recognizing how each part is labeled and arranged. These guides typically feature numbered sections or marked areas that correspond to individual elements. This makes it easy to trace each part’s function, whether it’s a small fastener or a major functional piece like the engine or carburetor.

Key Benefits of Using a Component Layout

Utilizing a component map provides several advantages, from improving repair accuracy to reducing downtime. It simplifies complex repairs by offering a clear, organized reference. With the layout in hand, locating replacement parts or troubleshooting becomes much more efficient, ultimately saving you time and effort during the maintenance process.

Identifying Key Components of the Chainsaw

Every chainsaw consists of several essential components that work together to ensure smooth operation. Recognizing these key pieces is crucial for performing accurate diagnostics and repairs. Each part plays a specific role, from powering the tool to ensuring the chain moves efficiently through wood. Understanding the function of each element will help in both routine maintenance and troubleshooting issues when they arise.

Engine: The engine is the heart of your chainsaw. It provides the power needed to drive the chain and allows the saw to perform its cutting tasks. Regular checks on the engine’s condition are vital for avoiding unexpected breakdowns.

Chain Brake: The chain brake is a safety feature designed to stop the chain in the event of kickback. It’s important to make sure the brake is in good working order to ensure maximum safety during use.

Fuel System: The fuel tank, carburetor, and fuel lines work together to provide the engine with the necessary fuel. Issues with the fuel system can lead to poor performance or difficulty starting the saw, making it essential to check these components regularly.

Drive Sprocket: The drive sprocket is responsible for transferring power from the engine to the chain. Any wear or damage to the sprocket can directly affect the performance of the chainsaw, making its inspection a critical part of routine maintenance.

How to Use the Chainsaw Component Guide

A component guide is an invaluable tool for anyone performing maintenance or repairs on their chainsaw. It provides a clear visual reference that simplifies identifying individual elements and understanding how they fit together. By using this guide effectively, you can streamline the repair process and ensure that each part is correctly installed or replaced.

Step 1: Familiarize Yourself with the Layout

Before diving into repairs, take a few moments to study the layout. Look for numbered or labeled sections, which correspond to different parts of the saw. This will help you quickly identify components during the repair or inspection process.

Step 2: Trace Connections and Functions

Once you have a basic understanding of the layout, focus on tracing the connections between parts. Many guides include arrows or lines showing how different components interact. This is especially useful when diagnosing problems or determining which parts need to be replaced.

Step 3: Locate Replacement Parts

When it’s time to replace a worn or damaged component, use the guide to find the exact part number. Many diagrams include detailed part lists, which you can cross-reference with the component map to ensure you’re ordering the correct piece.

By regularly using this visual reference, you can maintain a deeper understanding of your chainsaw’s inner workings, making future maintenance tasks easier and more efficient.