Maintaining and repairing your boat’s motor requires a clear understanding of its individual elements. Knowing how each component fits into the overall system allows for more effective troubleshooting and upkeep. Properly identifying the necessary pieces is essential for ensuring optimal performance.

In this section, we will break down the key elements of the system, helping you recognize the role of each part. Whether you’re performing routine maintenance or addressing specific issues, having a comprehensive view of these components will make the process much smoother.

By gaining insight into the system’s design, you can better anticipate needs and act quickly when issues arise. This knowledge empowers you to keep your equipment running efficiently and extend its lifespan. Make sure to review each part’s function and its place within the assembly for a complete understanding of your gear.

Understanding the Minn Kota Ultrex 112 Components

Every boat motor is a complex system of interconnected elements that work together to provide power and control. Familiarizing yourself with these individual components helps in both troubleshooting and optimizing the performance of the equipment. Knowing the function of each part allows for more efficient maintenance and timely repairs.

Core Mechanisms and Their Role

The main components of the motor include the drive unit, steering mechanism, and control system. Each part plays a crucial role in delivering the desired performance. The drive unit provides the necessary propulsion, while the steering mechanism ensures precise movement. The control system allows the user to manage settings and monitor the motor’s behavior.

Critical Elements for Smooth Operation

Regular attention to the key elements, such as propellers, mounting brackets, and wiring connections, is essential for preventing malfunctions. These components require routine checks to avoid issues that could impair functionality. Understanding how they interact within the system helps identify potential problems early, keeping your motor in top condition.

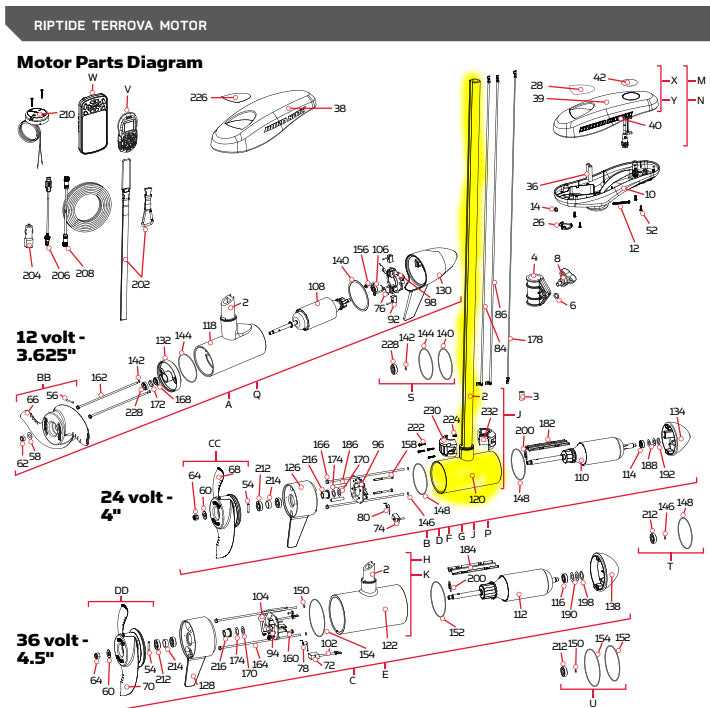

How to Read the Parts Diagram

Understanding how to interpret technical schematics is an essential skill for any boat owner. These diagrams provide a visual representation of the components and their relationships, helping you to easily identify each part and understand its function within the system. Reading these diagrams correctly is crucial for troubleshooting, repairs, and maintenance.

First, locate the key that explains symbols and numbers used in the schematic. This guide will help you match each part with its corresponding identifier. From there, examine how the elements are connected, ensuring you understand their interactions. Pay attention to any special instructions or notes that may indicate specific handling or installation procedures.

By mastering this skill, you can quickly navigate the schematic, making the process of maintenance and repairs more efficient and less time-consuming. This knowledge empowers you to manage your equipment more effectively and avoid unnecessary complications.

Essential Parts for Maintenance and Repair

Proper upkeep of your boat’s motor relies on understanding which components require regular attention. Certain key elements are crucial for ensuring the system continues to operate smoothly. Regular inspection and maintenance of these parts can prevent larger issues down the road, keeping your equipment in optimal condition.

Key Components to Inspect

Among the most vital elements to check regularly are the drive assembly, control system, and steering mechanism. These are the core systems that directly influence the motor’s functionality. The drive assembly is responsible for propulsion, while the control system allows you to manage settings, and the steering mechanism ensures precise navigation.

Additional Elements for Longevity

Equally important are the electrical wiring, mounting brackets, and propeller blades. These components, though often overlooked, play a critical role in maintaining the efficiency of the motor. Routine checks for corrosion, wear, or damage can help avoid costly repairs and extend the life of your equipment.