Maintaining small engines requires a deep understanding of their individual components and how they function together. Whether you’re working with a lawnmower, generator, or any other machine, knowing the structure and parts of the engine is crucial for effective troubleshooting and repairs.

In this guide, we will break down the key elements of an engine, offering detailed visuals and descriptions to help you identify and replace each part with ease. Understanding how the pieces interact ensures smoother maintenance and more efficient operation of your equipment.

By learning to navigate the detailed structure of these engines, you’ll be better equipped to handle repairs yourself, saving time and money while keeping your machines in peak condition.

Understanding the Small Engine Components

To ensure the optimal performance of any small engine, it’s essential to understand the various components that work together to generate power and drive machinery. Each part, from the intake to the exhaust system, plays a vital role in engine functionality and efficiency.

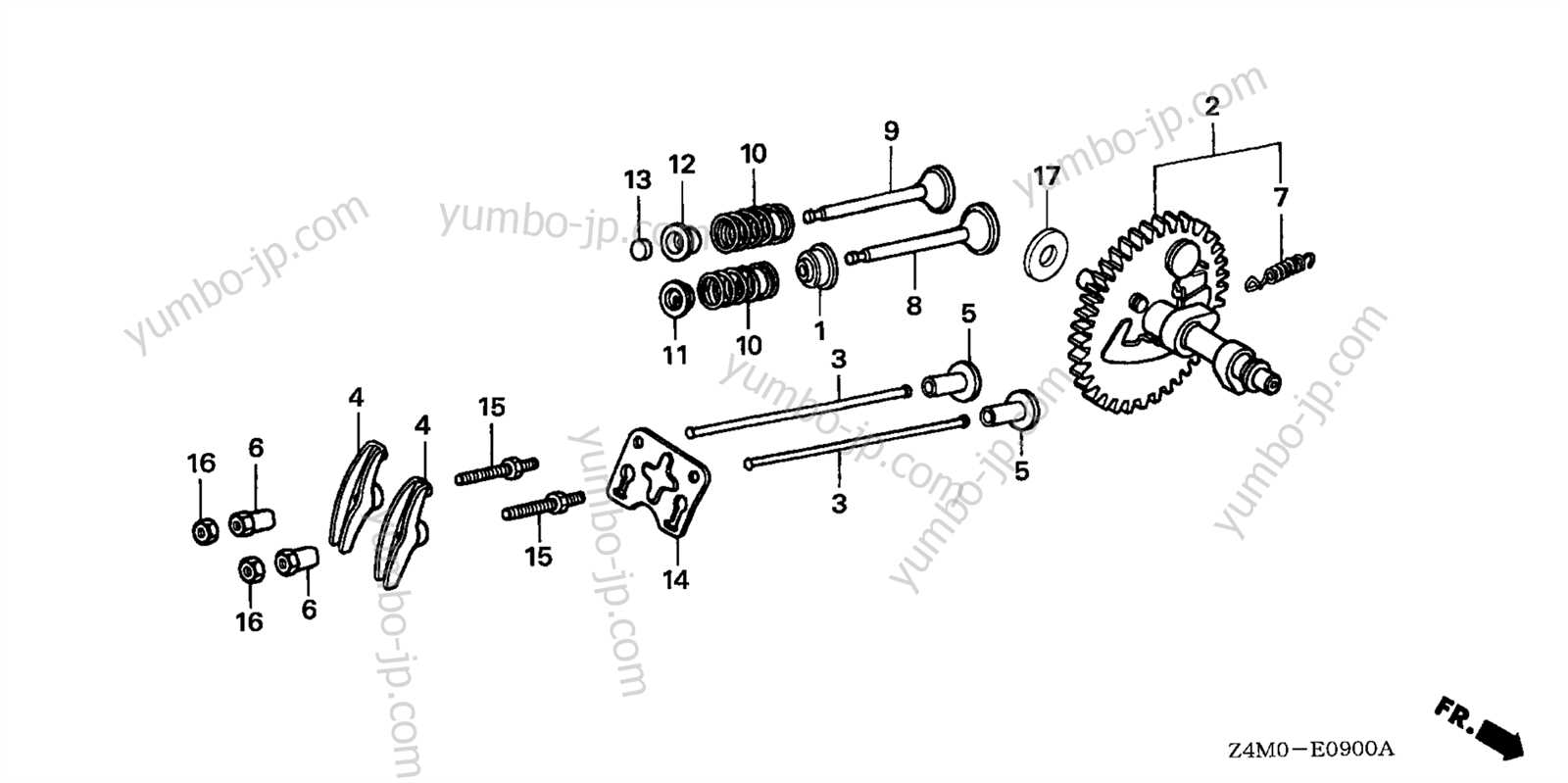

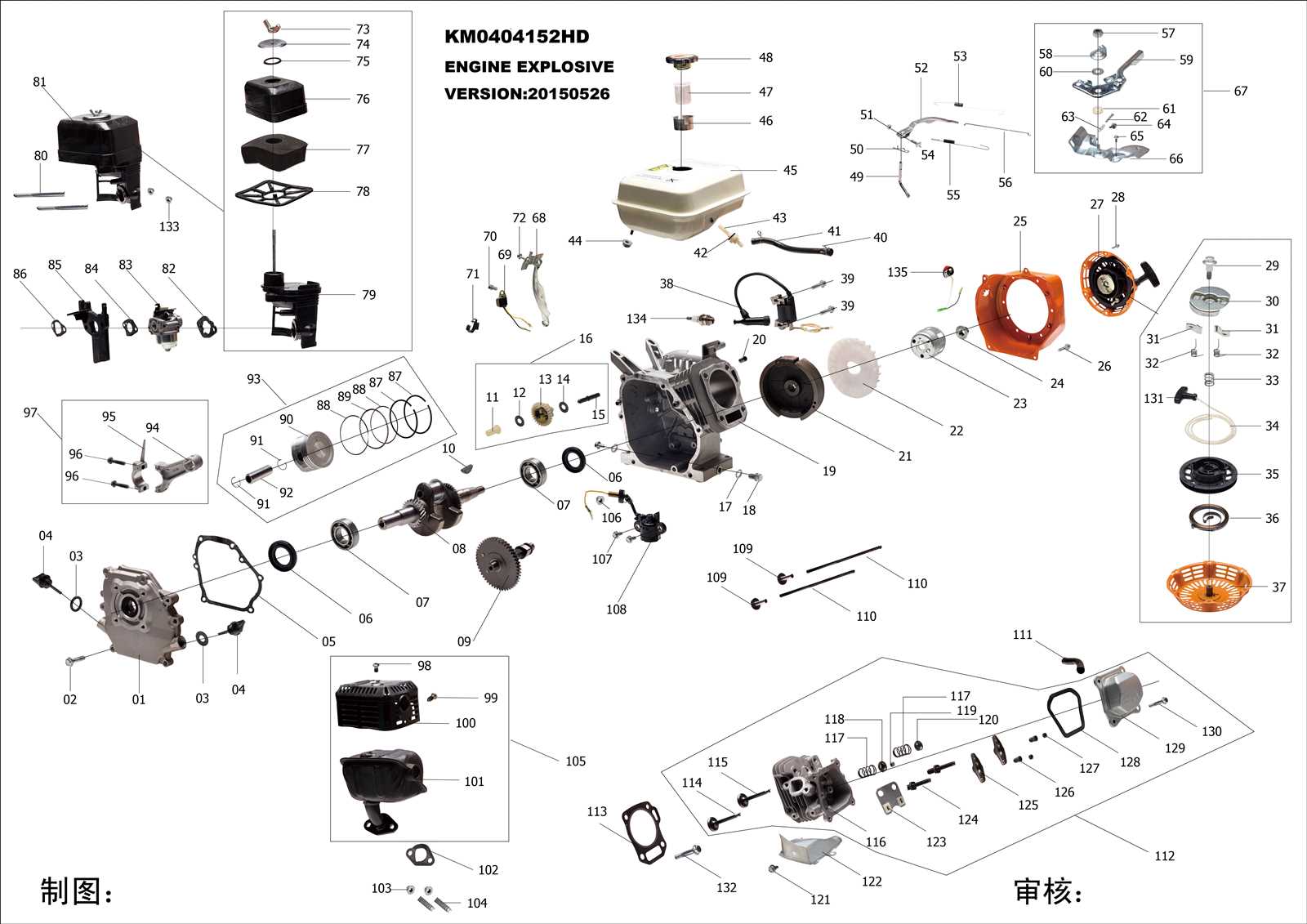

In this section, we will explore the main elements that make up a small engine. This includes the ignition system, fuel delivery mechanism, and the mechanical parts that support movement, such as the crankshaft and camshaft. By familiarizing yourself with these components, you’ll have a clearer understanding of how they interact and contribute to the engine’s overall operation.

Proper knowledge of these parts not only aids in routine maintenance but also helps identify potential issues before they become major problems. Regular inspections and awareness of how each component functions will ultimately extend the life of your engine and improve its performance.

How to Read the Components Breakdown

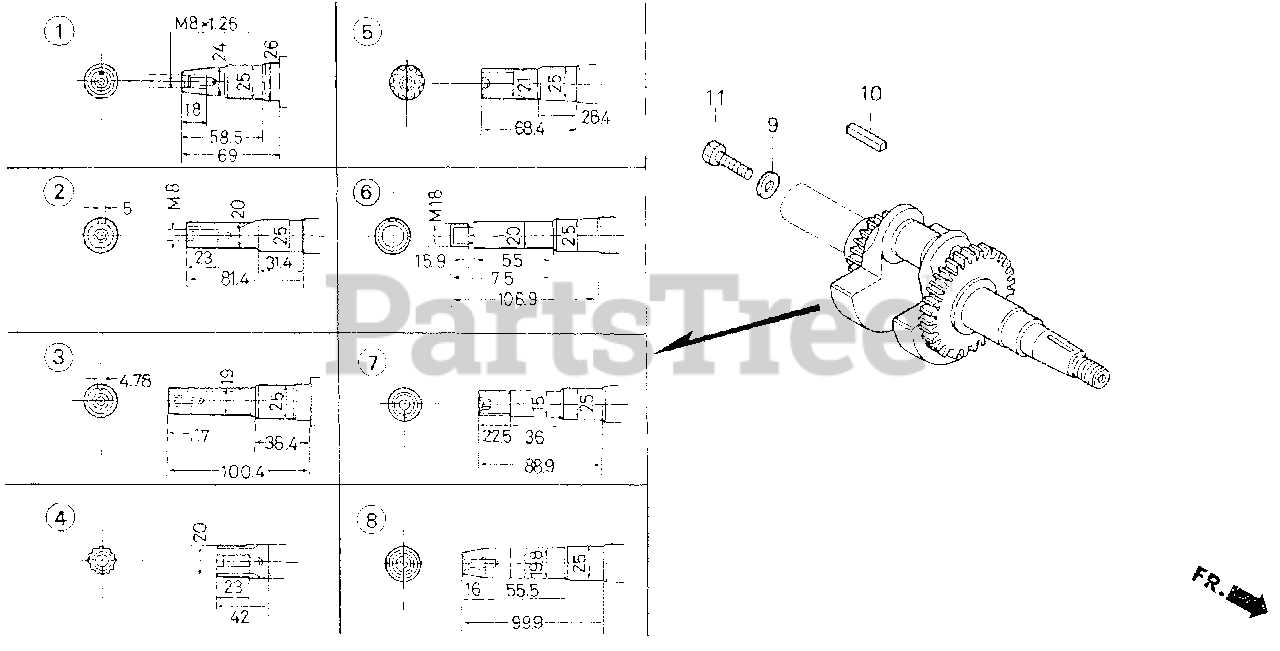

Understanding a schematic or visual breakdown of an engine’s structure is crucial for anyone looking to perform repairs or maintenance. These diagrams provide a detailed representation of the engine’s inner workings, showing how each component fits together and functions in unison.

When reading a schematic, focus on identifying key sections, such as the fuel system, ignition components, and moving parts. Each component will typically be labeled with a number or code, which corresponds to a specific part in the manual or inventory list. Familiarize yourself with these codes to easily match the diagram to real-world parts and ensure accuracy when replacing or troubleshooting components.

By carefully following the lines and labels, you can gain a better understanding of how the engine is assembled and identify potential problem areas quickly. This knowledge allows you to confidently navigate maintenance tasks and make informed decisions about repairs or upgrades.

Common Issues with Engine Components

Even with proper care, certain issues can arise in the components of small engines, which may hinder performance or cause complete failure if not addressed. Recognizing these common problems early on can save time and prevent unnecessary damage to the machine. Below are some of the frequent issues that owners encounter.

Fuel System Blockages

One of the most common issues in small engines is fuel system blockage. Dirt or debris can accumulate in the fuel lines or filter, restricting the flow of fuel. This often leads to engine stalling or difficulty starting. Regular cleaning and replacing filters can help prevent this issue.

Ignition System Malfunctions

Another common problem is malfunctioning ignition components, such as spark plugs or coils. A worn-out spark plug can result in poor combustion, causing the engine to misfire or fail to start. Replacing spark plugs at regular intervals ensures smooth ignition and reliable performance.

By being aware of these frequent issues and performing preventive maintenance, engine owners can significantly extend the life of their machinery and avoid costly repairs.