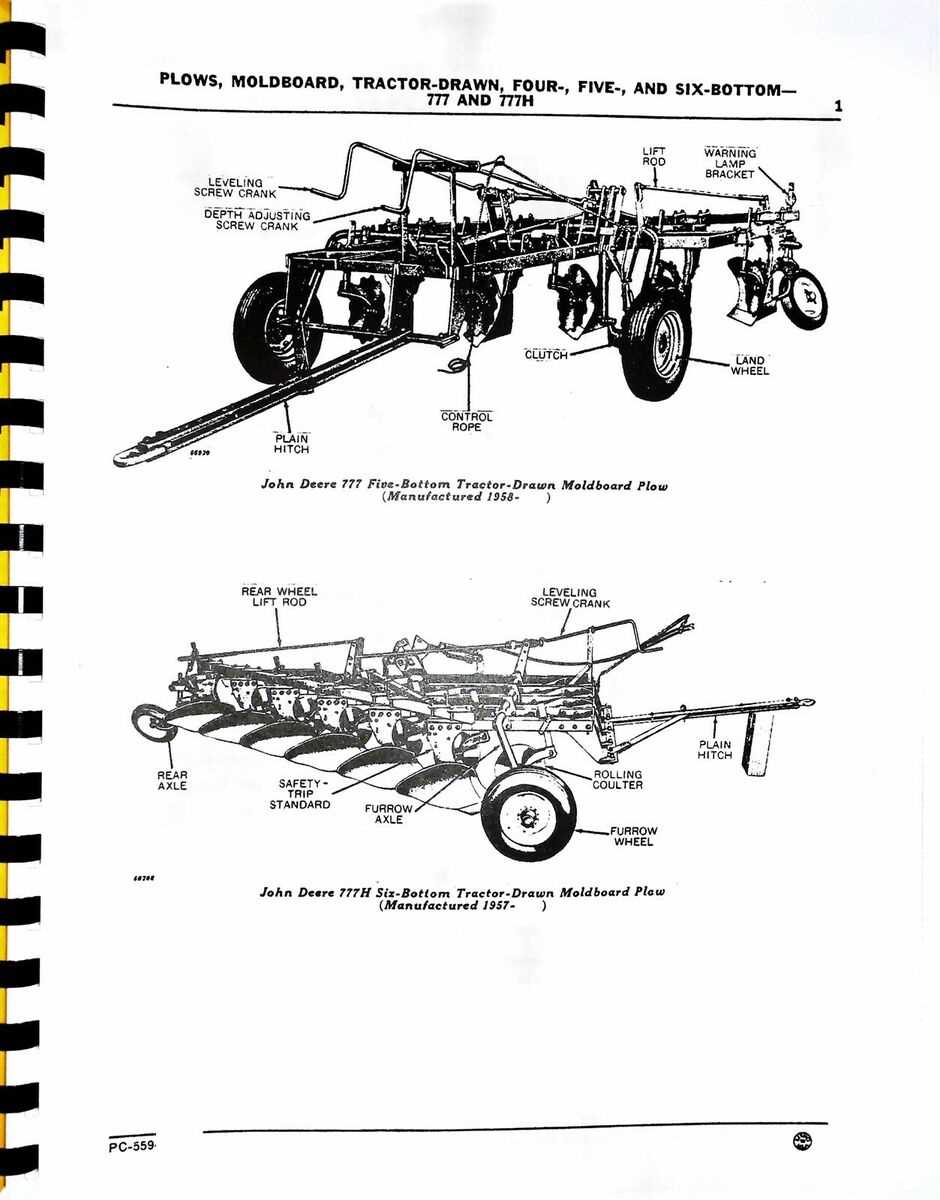

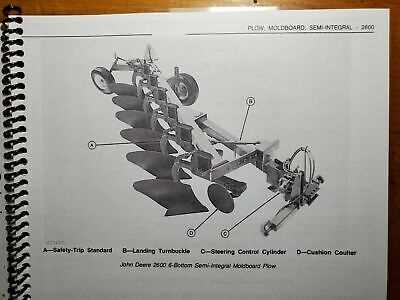

In agriculture, a crucial tool plays an essential role in soil preparation. This equipment, designed for tilling and turning the earth, consists of several critical elements that contribute to its efficient function. Each part has a specific purpose that enhances the overall performance of the machine, ensuring smooth operation during farming tasks.

Familiarizing yourself with the various components and their individual functions can help users maintain and optimize the tool for long-term use. From cutting edges to support frames, these elements work together to achieve precise soil cultivation, which is vital for successful planting seasons.

Understanding how these components interact will not only aid in effective maintenance but also provide insights into their role in improving productivity in agricultural practices. Proper knowledge ensures better decision-making when using, repairing, or upgrading the equipment for specific farming needs.

Understanding the Key Agricultural Tool Components

For efficient soil cultivation, the functionality of the equipment relies heavily on its individual components. Each element is designed to serve a distinct purpose, working in harmony to ensure optimal performance. Knowing how these parts work together is essential for anyone involved in farming or equipment maintenance.

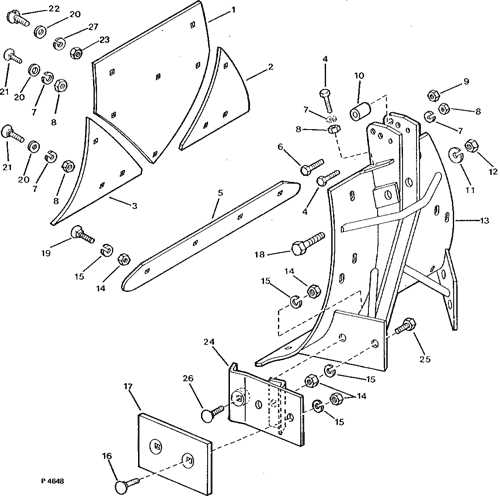

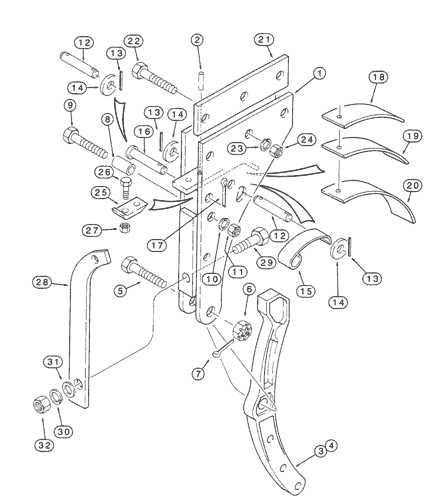

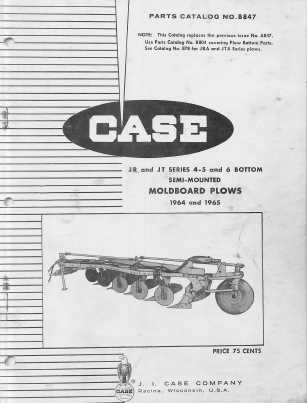

The main components of this agricultural tool include cutting edges, frames, and various support structures. Together, they help achieve the desired soil turnover, preparing the land for planting. Each part must be maintained properly to ensure the machine’s overall efficiency and longevity.

Understanding these components allows for better decision-making when it comes to repairs, replacements, or upgrades. Recognizing the role of each element helps users make informed choices, enhancing the tool’s functionality and extending its useful life in the field.

Key Parts of an Agricultural Tillage Tool

Understanding the individual components of this soil-turning equipment is crucial for proper maintenance and effective use. Each element plays a specific role in ensuring that the machine performs efficiently, making it essential to recognize how they work together to achieve optimal soil preparation. The most critical parts of this machine are designed to interact seamlessly, ensuring maximum productivity in agricultural tasks.

Cutting and Shaping Elements

The cutting edges are vital for slicing through the earth, creating clean, precise cuts. These elements are typically made from durable materials to withstand constant pressure and wear. Their primary function is to break and lift the soil, which is necessary for turning it over and creating a smooth surface for planting.

Support and Framework

The frame and support structures provide stability and durability. These components hold everything together, allowing the tool to function properly under heavy use. They are designed to bear the load of the entire equipment while maintaining its balance and ensuring that each element remains in place during operation.

How to Maintain Agricultural Tillage Tool Components

Regular maintenance is key to ensuring the longevity and efficiency of soil-working equipment. Proper care of its individual elements will prevent wear and tear, reduce the need for costly repairs, and improve overall performance. Regular inspection and timely replacement of worn-out parts help keep the tool running smoothly throughout the season.

Cleaning and Inspection

After each use, it is important to clean the components thoroughly to remove soil, debris, and other materials that can cause corrosion. Inspect the edges for signs of damage or wear. Any cracks, dullness, or bends should be addressed immediately to maintain optimal cutting ability and prevent further damage.

Lubrication and Adjustment

Lubricating the moving parts helps reduce friction and ensures smoother operation. Apply appropriate lubricants to areas such as joints and pivots, where movement occurs. Additionally, check the alignment of the framework regularly to ensure the components are properly positioned for efficient functioning. This simple practice will help extend the machine’s service life and maintain its performance.